Iíve been thinking about necking up some more 6.5-.284 Lapua brass for use in a .284 Winchester, and ways of reducing the occurrence of donuts. The same would apply to other similar forming where the case neck is being taken up in calibre. Not that bullets will necessarily be seating deep enough to where the shank will contact the problem area, but you never know initially just what engagement or jump a given bullet is going to prefer and so how deeply it will end up being seated. I figure it is best to prepare the cases to accommodate all eventualities and try to remove any donut and have the inside of the necks as uniform in diameter as possible - top to bottom.

There are two methods commonly used to fix the donut issue when taking necks up to a larger calibre: use an inside neck reamer to remove them, or turn off the excess brass with outside neck turning gear after expanding them to the new calibre.

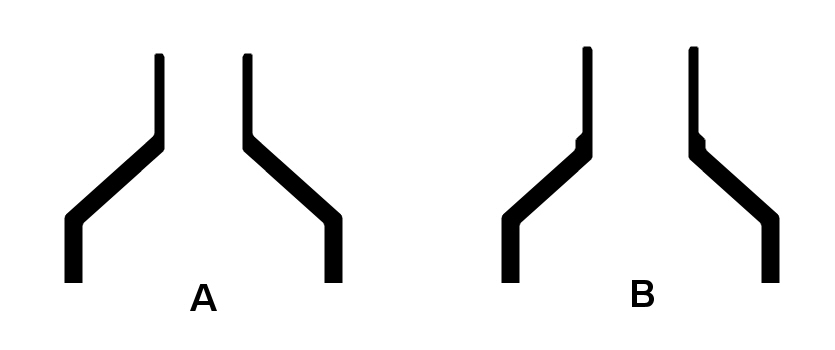

Looking at how donuts are formed using diagrams that show the cross-sectional profile of the top part of the cases: running an expander through the neck should give B shown below right from the parent case A in the original calibre, where a portion of thicker shoulder brass is moved around into the bottom of the necks.

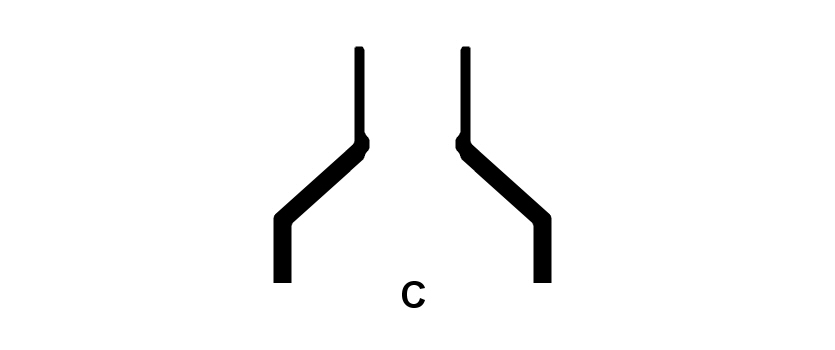

On firing, the brass in the neck conforms to the chamber profile, and a donut develops internally, shown in C.

One strategy to reduce this is to take the expanded brass at B and turn the cases, removing the excess thickness at the base of the necks while perhaps also reducing the shoulder thickness in the process to much the same as that of the neck, as shown below in D. The case is then fire formed to E, hopefully now without a donut developing.

The outside neck turning gear will require a cutting bit ground for the appropriate shoulder angle. Most reloaders seem to take this indirect route of outside turning to prevent donuts rather than the alternative of reaming them out.

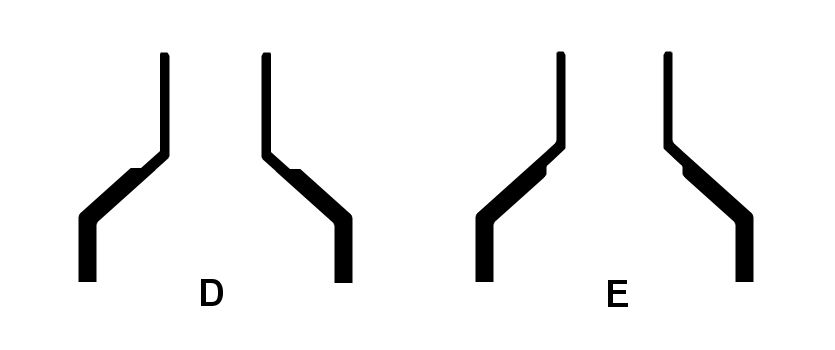

However I have found that B is not a true representation of what happens when the necks have an expander run through them. My observation is that an expander is not effective in pushing ALL the excess brass to the outside of the cases and instead leaves partial donuts, as pictured in F, unavailable for removal solely with outside turning.

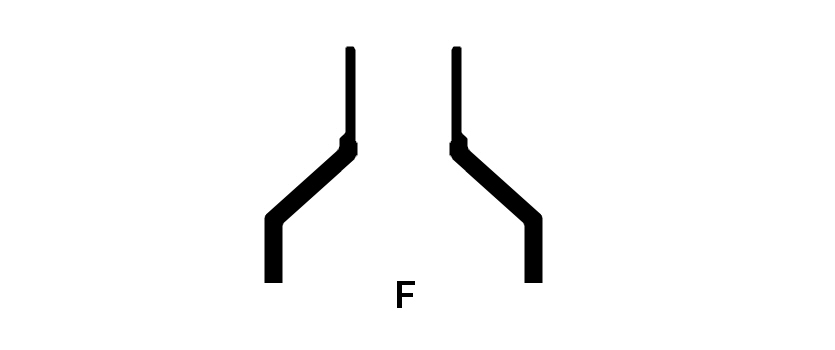

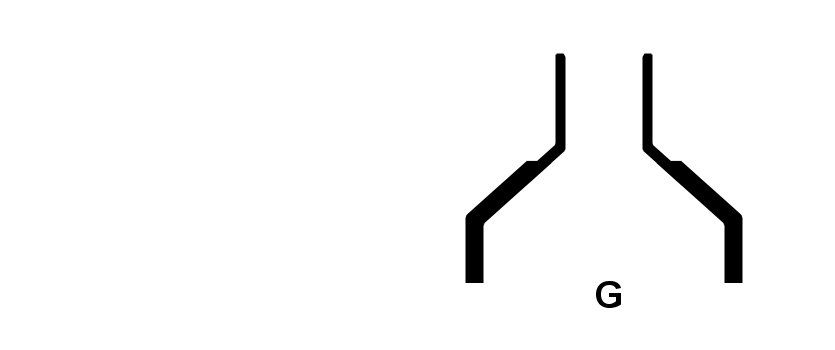

So my question is: has anyone here instead gone down the path of thinning the shoulders of the cases in the

original calibre down to the same thickness as the necks prior to expanding, as a method for reducing the occurrence of donuts? That is from A to G below

Iíve not tried this but am thinking that G may be more likely lead to donut-free cases?

For the .284Win this will mean thinning the shoulders of the 6.5-.284 brass prior to expanding the necks. The necks can still be uniformed again for thickness once at .284Ē and at the same time the shoulders checked and re-cut as necessary. Extra work, as the cases will be turned twice, but hopefully no donut.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 5 of 5

Thread: Another way to avoid a donut ?

-

17-01-2020, 10:02 PM #1

Another way to avoid a donut ?

-

-

17-01-2020, 10:35 PM #2Member

- Join Date

- Jul 2012

- Location

- Napier, Hawkes Bay

- Posts

- 4,460

From my experience necking up the same cases I would concur on your theory of partial removal of donuts resulting in your figure F

I reckon your theory is sound.

I've ended up neck turning mine twice, once after necking up then again after firing a couple of times.

-

18-01-2020, 12:02 AM #3

Yep pick f is where I ended up, I inside reamed fired cases but neck turning into the shoulder as you describe should pre empt it forming.

Or you could run 284 brass and save yourself the hassel?

Sent from my S60 using Tapatalk"Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

-

18-01-2020, 07:34 AM #4

Similar Threads

-

Another Lever Action thread question. Wanted to avoid thread drift

By ZQLewis in forum Firearms, Optics and AccessoriesReplies: 11Last Post: 29-03-2019, 09:41 PM -

22 LR MAXXTech 40gr LRN. Avoid this crap ammo.

By Simon in forum Questions, Comments, Suggestions, Testing.Replies: 1Last Post: 30-04-2017, 01:29 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

1Likes

1Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks