Hey team, does anybody do annealing of cases?

I'm looking into doing it and was wondering if the canister attached blow torches from bunnings etc get hot enough to do it?

Any tips and tricks would be appreciated

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 25

Thread: Blow torch for annealing

-

08-12-2019, 06:59 AM #1Member

- Join Date

- May 2016

- Location

- Nz

- Posts

- 1,350

Blow torch for annealing

-

-

08-12-2019, 07:02 AM #2

Plenty of vids on youtube about it, I reckon they would.

I'll be giving it a crack when I get my WSM back from the shop.

-

08-12-2019, 07:28 AM #3Bah, humbug !

- Join Date

- Nov 2013

- Location

- Auckland, until I can escape south....to Southland.

- Posts

- 1,696

I use one of those blow torches powered by a blue ‘camping gas’ cylinder

Same one as the cookers use

Works for me.

I’m highly unscientific, anneal every 4 reloads, hold the case in the flame, rotating it, until I start to feel the heat

through my fingers, then drop it in water.

Seems to improve neck tension.

Then again, maybe I’m fooling myself !

It’s part of the reloading procedure I’ve ended up doing, anyway.He nui to ngaromanga, he iti to putanga.

You depart with mighty boasts, but you come back having done little.

Sounds like a typical hunting trip !

-

08-12-2019, 07:29 AM #4Member

- Join Date

- Jun 2019

- Location

- Tasman

- Posts

- 506

They get plenty hot enough. The problem is moderating the heat so you don’t over anneal and ruin the brass.

-

08-12-2019, 07:41 AM #5

What's everyone's thoughts about dropping them in water ? I've read that dropping them in water can create inconsistencies and better off dropping them in a tray to cool down, also best to do in a slightly darkened rooms you can see when they turn to a dark cherry red which is apparently all they need.

-

08-12-2019, 08:05 AM #6

When the case area being heated starts to develop the blue tint, itís around the correct temp.

Any more and you are overheating it.

You can get technical and apply templaq which turns colour, but I canít be fussed.

I do what Frogfeatures does, hold by hand in a camp cooker flame.

Dropping in water isnít really needed, air cooling is fine.

The net has instructions on how to make an automated annealing set.Welcome to Sako club.

-

08-12-2019, 08:33 AM #7Member

- Join Date

- Feb 2013

- Location

- Wanganui without an "h"

- Posts

- 3,023

-

08-12-2019, 08:40 AM #8Member

- Join Date

- May 2016

- Location

- Nz

- Posts

- 1,350

Cheers, that's the type I was looking at

Thanks for all the info team. Might do a bit of experimenting over the break. 10 reloads out of my 303 brass so far.

Neck tension is a bit loose after resizing so must be time to anneal.

Head thickness is fine after I cut a case lengthwise

-

08-12-2019, 08:46 AM #9Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,435

I just use my single burner little camping stove. Works fine.

-

08-12-2019, 08:49 AM #10Member

- Join Date

- Aug 2016

- Location

- Blenheim

- Posts

- 332

Yeah I use one from bunnings, but I brought a hose to connect it to my 9Kg LPG bottle for a more consistent pressure and economically it makes annealing way cheaper!

-

08-12-2019, 09:20 AM #11

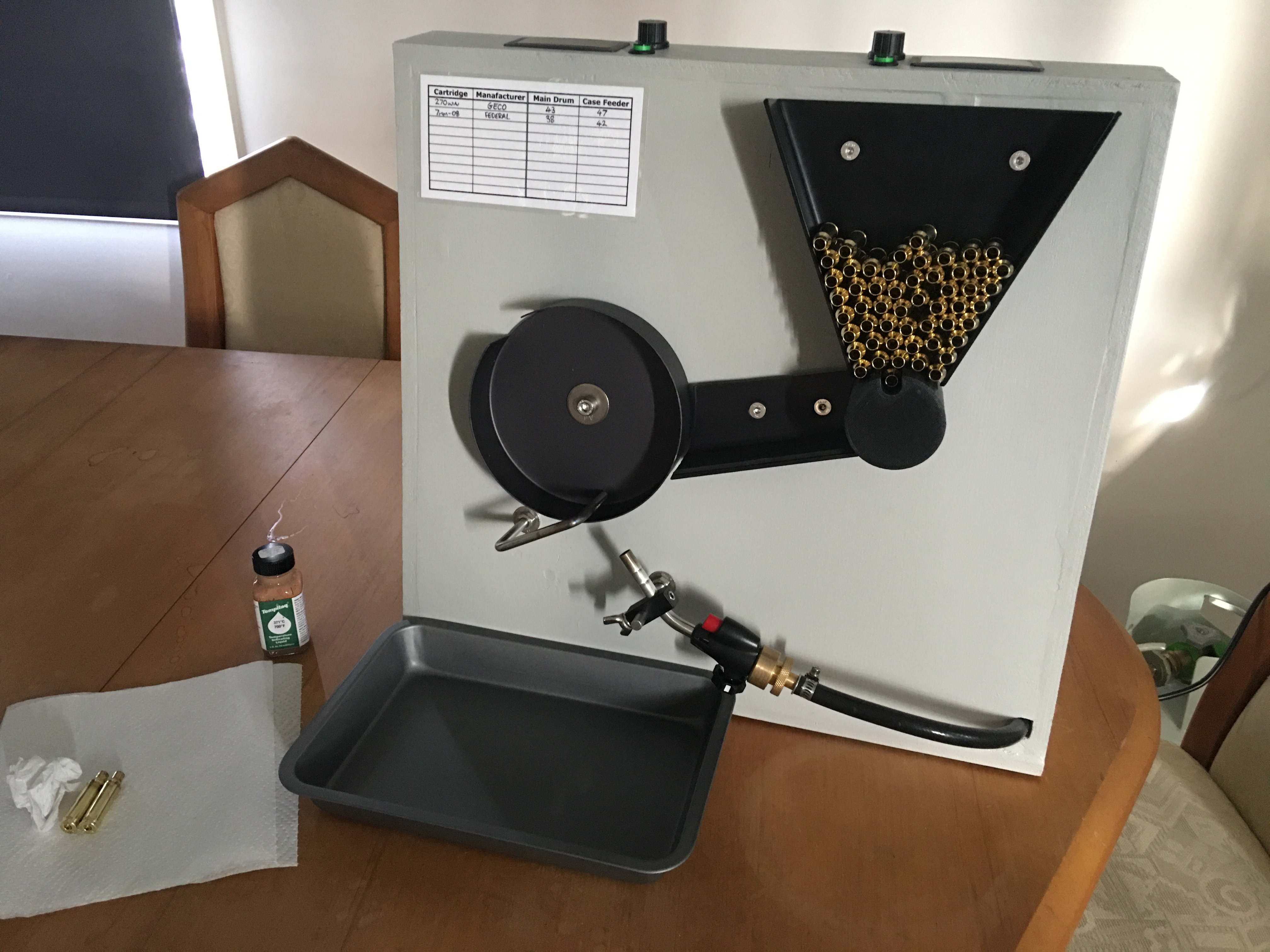

Built one of these with parts off AliExpress. Costs about $50 and a couple of hours of assemble time. Used tempilaq (from Servotech in AKL) to get the correct heat level.

https://youtu.be/Y2TbYhYKsys

Sent from my iPhone using TapatalkWhat you see, is what you get!

-

08-12-2019, 09:39 AM #12Member

- Join Date

- Aug 2016

- Location

- Blenheim

- Posts

- 332

@janleroux Nice! Really simple, I opted to add the hopper using Skippy’s YouTube videos to allow me to do other processes as they anneal, such as decapping another batch

-

08-12-2019, 09:52 AM #13

@Oli1102 you are a step or so ahead of me, but that is on my todo list. As is I have annealed about 500 cases with this setup. Takes me about 10min to do 100 cases, so not too much drama. Use the standard blue gas torches - I just bought another (the cheaper) torch tip from Mitre10. The fancy one that has the lighter built in did not give a nice pencil flame.

Sent from my iPhone using TapatalkWhat you see, is what you get!

-

08-12-2019, 10:03 AM #14Member

- Join Date

- Aug 2016

- Location

- Blenheim

- Posts

- 332

Yeah I have found it doesn’t give a nice pencil flame with the one I have, so had reservations about it when I started. I have found it to work fine and heat evenly though and the width of the flame when centred on the neck/shoulder junction covers the shoulder and most of the neck. I think it might actually heat more evenly the whole annealing area rather than focusing on one point and relying on the heat to transfer up the neck and down the shoulder... but in reality they all work.

-

08-12-2019, 10:22 AM #15Member

- Join Date

- Aug 2016

- Location

- Blenheim

- Posts

- 332

Also, I would say the hopper hasn’t saved me anytime yet as I’m still working on getting it 100% reliable so I usually end up watching it anyway to catch the 1 in 50 cases that bounces off or stops halfway down the ramp. I have only done maybe 250cases total so far on it.

Similar Threads

-

Anybody had their dog blow an ACL joint?

By Lentil in forum Hunting DogsReplies: 36Last Post: 23-01-2025, 02:47 PM -

Study on Bullet seating force with annealing vs not annealing

By Matt Findlay (AMP) in forum Reloading and BallisticsReplies: 9Last Post: 21-09-2019, 11:33 AM -

Ruahine Blow Out

By Dundee in forum The MagazineReplies: 74Last Post: 07-02-2017, 09:30 PM -

That must blow them up ?

By john m in forum HuntingReplies: 17Last Post: 14-11-2013, 07:58 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

27Likes

27Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks