Hey lads

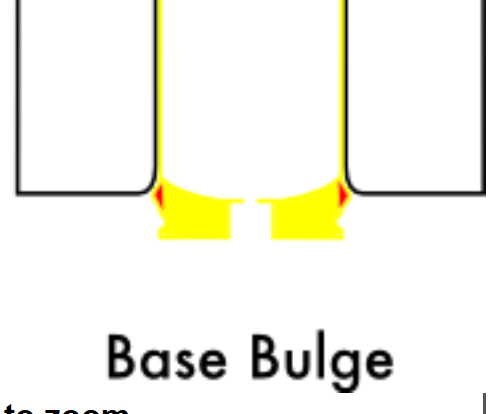

Below is a picture of my 9.3x62 brass, the case is obviously a rimless design however, at the base you can see a prominent ring at the bottom which looks like a belt. The brass has been fired no more than three times and is full length sized. My mate and I were discussing this and we came up with two possibles causes:

1. Beginning of case head separation

2. I am not fully sizing the brass properly.

Any input appreciated

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 15

Thread: Brass issue?

-

14-03-2016, 08:45 PM #1

Brass issue?

-

-

14-03-2016, 09:03 PM #2

Looks like case head separation to me but a slightly clearer picture would be good.

I'd cut it open with a hack saw just above the ring and have a look what's going on in there.

Do any of your other cases have signs of a light coloured ring in the same area?

You may be oversizing the brass or chamber may be out of spec so might be worth checking with go/no go gauges or get a smith to take a look.

-

14-03-2016, 09:05 PM #3

Looks like seperation but its very low. Cut one long ways and see whats happening. How many like it and are they all similar looking?

-

14-03-2016, 09:06 PM #4

-

14-03-2016, 09:14 PM #5Member

- Join Date

- Mar 2013

- Location

- Bell Block NZ/Northern Alberta Canada

- Posts

- 1,149

I am going to say that is the limit, that the full length sizing die, sizes the case down, its very low and the brass, should be starting to thicken by that point.

perhaps mark a case with a felt marker, and resize it. to find out.

-

14-03-2016, 09:16 PM #6

There's about 7 out of 60 that look like this. This was the worst of thhe lot. I thought case head seperation occured a bit further up? I bought the rifle new and it's fired around 50rnds.

Edit* Just went back to the press and wound the die in a further 3/4 turn, on some brass it has removed the bump others have been reduced but belt is still visible. However in the process of doing this could I potentially be bumping the shoulder back to far?Last edited by mawzer308; 14-03-2016 at 09:31 PM.

-

14-03-2016, 09:56 PM #7

The case web is solid at that point just the flash hole so not separation. Do those cases chamber freely, if your fl resizing they should just drop in and the bolt close with no resistance. I assume you lube the cases. Can you measure the bulge with a micrometer? I sometimes get something that looks similar when resizing dirty brass, the lube and die polish the case where it is resized and it looks like their is a ridge at the bottom.

-

14-03-2016, 10:13 PM #8

Hi there,

Something from ballistic tools website

"As the illustrations show, the bottom of the die is rounded, and much of the base is in the shell plate. Most dies will only size to within about 1/4th inch of the base of the brass. If the head of the brass is expanded or flowed due to overpressure, loose chambers, or both, then a standard die, or even a "small base" die can't do anything about it. This effect, when pronounced, will often leave a visible ring on the brass near the base. The presence of a ring does not necessarily mean that the brass has flowed to the point where it will not chamber, but it is a sign that the brass has begun expanding in the section that a sizing die can't reach."

Also can you measure the shoulder bump with verniers and a spacer ( right sized tube etc) of some sort to see if it is bumping the shoulder more than it needs. It looks as if the brass is thicker under that ridge.

The edge of the die has a chamfer on it's circumference?

Good luck it looks like a sharp wee ridge somebody will know.

-

14-03-2016, 10:42 PM #9

Cheers lads all really good feedback. Sorry I don't have a micrometer to check just some cheap calipers. Some of the cases were a bit tight but nothing major. The rifle is unique as it is a straight pull action and very similar to a semi automatic. Bugbait that diagram pretty much sums up what is happening when sizing. But I'm not sure if its caused during firing or sizing.

-

15-03-2016, 06:11 AM #10northdudeGuest

have a look at the case after youve sized it if the mark appears after youve sized it and wasnt there berore youll know its when you sized it

-

15-03-2016, 07:29 AM #11Member

- Join Date

- Mar 2013

- Location

- Bell Block NZ/Northern Alberta Canada

- Posts

- 1,149

The 9.3 x62 doesn't have much shoulder, I would be more worried, about the shoulder than the ring on the brass,

3/4 turn is quite a lot, you may end up with head space issues, I would recommend you reset the die, to the instructions, or at least, only resize a few brass, and test before doing any more.

If you have any factory unfired rounds, you can put them in shell holder, and screw the die body down on to it, remove, and then install the decaper pin etc.

-

15-03-2016, 07:44 AM #12Member

- Join Date

- Feb 2014

- Location

- Hawkes Bay

- Posts

- 2,673

Simply looks like an end of sizing mark to me.

If you're ever suspicious of pending separation, straighten out a paper clip then bend the last 3-4mm to a right angle after pointing it slightly. Feel down inside the case wall til you hit the bottom. A thinned portion will have increased friction and if it's very near separation, you'll feel a definite depression. Practice on new and old cases and you'll soon get the idea

-

15-03-2016, 08:39 AM #13Yeah it is a lot, I mainly just did that to see what would happen to the ring. When reloading I set up as per instructions ie. Screw the die in until it contacts the shell holder then a further quarter turn before locking the die off. Will also try a factory unfired round as you stated.3/4 turn is quite a lot

Is that something to worry about as I think this may be the number one cause. I can just catch my finger nail over it.Simply looks like an end of sizing mark to me.

-

15-03-2016, 09:27 AM #14

When reloading my 9.3x62 I full length sized once fired Norma cases. The second firing on the first two cases had case head separation. I biffed the other cases I had done. I now setup the full length sizer so it only sizes 3/4 of the neck and doesn't touch the shoulder. No issues with case head separation or chambering.

-

15-03-2016, 10:36 AM #15

Similar Threads

-

Scope... Issue

By Dr. Watson in forum Firearms, Optics and AccessoriesReplies: 40Last Post: 24-02-2015, 10:20 AM -

Sako a7's possible issue

By Grunta in forum Firearms, Optics and AccessoriesReplies: 11Last Post: 05-04-2014, 05:02 PM -

Issue with my gsp

By Tristan in forum Hunting DogsReplies: 6Last Post: 05-12-2013, 10:37 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

2Likes

2Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks