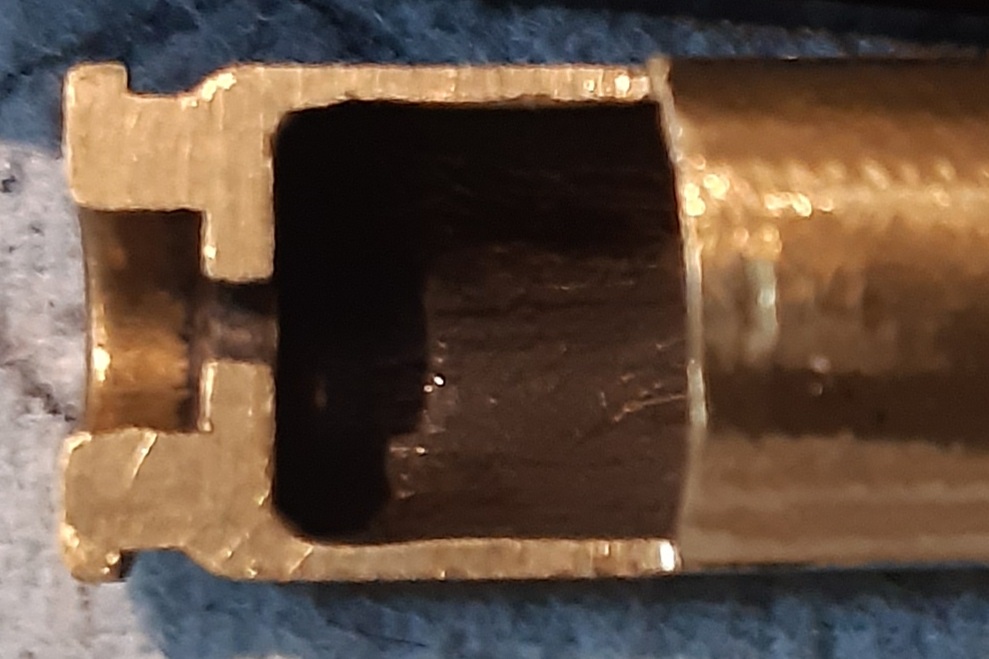

Just posting a pic of it. 3 cases.

The sideways one has no separation just the bright line from stretch/size over many cycles.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 20

Thread: Case base separation

-

12-10-2024, 08:06 PM #1Member

- Join Date

- Mar 2012

- Location

- Waikato

- Posts

- 2,189

Case base separation

-

-

12-10-2024, 08:11 PM #2Member

- Join Date

- Feb 2019

- Location

- Tarras

- Posts

- 1,438

The way ur sizing them causes that just played this game with my 270

-

12-10-2024, 09:02 PM #3Member

- Join Date

- Jan 2020

- Location

- Tokoroa

- Posts

- 126

Sorry to assume you are new to reloading but find someone more experienced to show you how to set up your sizing die.

-

12-10-2024, 09:16 PM #4

-

12-10-2024, 10:42 PM #5Member

- Join Date

- May 2012

- Location

- Sydney

- Posts

- 1,825

How many firings, they donít live forever?

Sent from my iPhone using Tapatalk

-

12-10-2024, 10:44 PM #6

Thanks for sharing photo. It's good to see them. If you feel like cutting one lengthwise...it's enlightening too.

75/15/10 black powder matters

-

13-10-2024, 06:39 AM #7Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,652

-

13-10-2024, 07:56 AM #8

Buy redding comp shell holders.

Sorts this shit out.

As far as screwing your dies in until you can close your bolt.

It semi works but not consistently as really needed.

There a great podcast from the vice president from redding that explains all this.

Sent from my SM-A556E using TapatalkMy favorite sentences i like to hear are - I suppose so. and Send It!

-

13-10-2024, 07:59 AM #9

The bright line on case 1 vertical just shows the junction between web and drawn section of the case. You will see on the separated ones that this occurs above the web and it's generally caused by continual full length sizing after every firing. Neck sizing greatly extends case life and can be done with a full length die by winding it out a turn or two . This illustration of a case sort of explains things best.

-

13-10-2024, 09:27 AM #10Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 6,168

Bushing neck sizing dies are another way to avoid this. I used to use the Lee collet dies, but they can end up making your cases necks look like they've been through the willi wonka chocolate factory and fell into the striped candy machine. It doesn't seem to affect anything but I just found the visuals a bit weird... Also a bit harder to adjust neck tension with the collet type setup, whereas the bushing dies you can swap bushings in and out in 1thou increments.

I would second the competition shellholder suggestion, pricey but worth it. Start with your full length sizer die setup on the longest shellholder, and if you end up with a bit of resistance on bolt closing drop back in four steps until the bolt closes with no resistance.

The cheat way here is what I did, use the competition full length bushing die and get the best of both worlds - bushing neck sizing with the control of shoulder length with the die set up to just bump the shoulder back if it's needed. I think (I'd have to check my notes now) but I think I was getting away with the FL-B die set up on the longest shellholder and running on the middle one. Also I recall a 333-sized bushing for what thats worth. With the bushing out, the FL die becomes a handy body and shoulder bump die leaving the neck alone. I've used this a couple of times for bumping the shoulder on live rounds where some crap got caught up in the works leaving to a couple of rounds that were too long to comfortably chamber. Just a quiet little bump with everything cleaned up, and problem solved back to chambering easily. Saves pulling the rounds apart and decapping a live primer with a standard full length die to run the case over the expander ball.

-

13-10-2024, 11:25 AM #11Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,574

Im not certain @Bagheera was looking for advice, more making a statement that if you work the brass enough this is what eventually happens? I expect this brass has had many firings.

With my .223 brass I eventually get little splits in the necks and it's time to biff them. I don't anneal .223. And I don't wring my hands when they split cos they have served me well with multiple uses.Out beyond ideas of wrongdoing, and right-doing, there is a field. I will meet you there.

- Rumi

-

14-10-2024, 10:25 AM #12Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 3,199

Greetings,

Granted that @Bagheera may have posted his photo for our enjoyment and education perhaps some more of the same might be appropriate from an old codger.

Over the last 50 years I have learnt several things about handloading so here is a lazy mans approach to sizing and case prep.

Loads for my old soldiers have loads that are light enough to only never need FL sizing. .303 cases are neck sized in a Lee Loader and have a .303 expander button run in and out of the neck. .30-40 Krag cases are neck sized in a .308 neck die with only half the neck sized. 6.5x55 cases are neck sized in an old 6.5x55 neck sizing die. None of these dies oversize the neck.

Loads for most of the other rifles are FL sized using the Redding competition shell holders to get minimal shoulder set back and easy chambering. Early on I used to neck size these loads but have now abandoned that after problems with hard chambering. I did tinker with partial sizing using a FL sizing die but ran into problems with the less tapered cases like the .308. For more tapered cases it may work after a fashion for some but I abandoned it. The partial sizing can move the shoulder forward and create its own set of problems.

I anneal my cases using a candle. I hear the howls over this already but there is a technique to it and for me it works well. The biggest problem with annealing is getting the same level of annealing on all cases. The AMP annealers rightly get top marks for this but I have yet to take the plunge. Cases are trimmed every load.

All of this is work in progress and some new bits of kit may appear on the bench over time, perhaps some of the Redding FL bushing dies for some of my target rifles. Time will tell.

Regards Grandpamac.

-

14-10-2024, 05:40 PM #13Member

- Join Date

- Jun 2014

- Location

- CNI

- Posts

- 6,000

Herewith a pic showing the beginnings of incipient head seperation. This cartridge has plenty of life in it yet, provided the shoulder is bumped .inimally load to load. You can see the beginnings of case wall thinning just abpve the web. This can easily be seen by looking down your case with a small penlight in a darkened room. You will see a dark groove inside the base of the case if incipient head seperation is present.

Summer grass

Summer grass

Of stalwart warriors splendid dreams

the aftermath.

Matsuo Basho.

-

14-10-2024, 08:47 PM #14Member

- Join Date

- Mar 2012

- Location

- Hastings

- Posts

- 2,950

-

14-10-2024, 08:56 PM #15Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,574

Similar Threads

-

Headspace gauge/ case head separation

By Porter83 in forum Reloading and BallisticsReplies: 24Last Post: 03-10-2024, 08:04 AM -

Case head separation

By No.3 in forum Reloading and BallisticsReplies: 12Last Post: 30-04-2024, 08:43 PM -

case separation

By garyp in forum Projects and Home BuildsReplies: 9Last Post: 10-08-2023, 09:33 PM -

Case head separation imminent

By veitnamcam in forum Reloading and BallisticsReplies: 56Last Post: 09-11-2022, 11:48 AM -

BA13 case head separation

By ebf in forum Firearms, Optics and AccessoriesReplies: 12Last Post: 17-09-2021, 08:03 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks