Hey Folks,

I thought this could be useful and might interest a few here.

I read about this technique on another forum and decided to give it a go. I wanted to make a chamber cast of my No1mk3 Enfield chamber to double check the groove diameter and neck diameter.

I can't find cerrosafe in NZ and didn't want to import some, so was looking for an alternative.

The process is pretty simple. First you combine the sulphur and graphite powder, I used about 4 tablespoons of sulphur to 1 tablespoon of graphite powder. You then slowly heat it on an element (no flames, sulphur catches very easily on an open flame.)

The melting temp of sulphur is about 125c, so I used a laser thermometer to set the element to about 150-160c. I had to sit my little pot of sulphur in the larger pot as I was using an induction element and the sensor wouldn't pick up the small one by itself. This actually worked quite well as it was a decent wind barrier. I left this to slowly heat up and melt, which took about 15min.

While that was heating I pushed a plug of cotton rag from the muzzle to about 30mm from the end of the chamber and made a small funnel from a beer can to direct the liquid into the chamber. I should have made it a tight fit to the rear end of the chamber or sealed it somehow as I ended up with some overflow into the extractor groove and pressure relief hole, which is easy enough to deal with in an enfield, but on a standard bolt action would be a nightmare to clean up.

Once the mixture was well melted I gave it a quick stir and then poured it into the chamber. I didn't preheat the chamber at all and didn't even clean it properly beforehand. I got a couple of very small wrinkles that looked to be oil contamination, but the casting filled out completely, so pre heating the chamber doesn't seem to be that necessary. I have read that you can wipe the chamber/throat area with a graphite covered patch before casting to make it release a little easier. I had no trouble gently tapping it out with a cleaning rod.

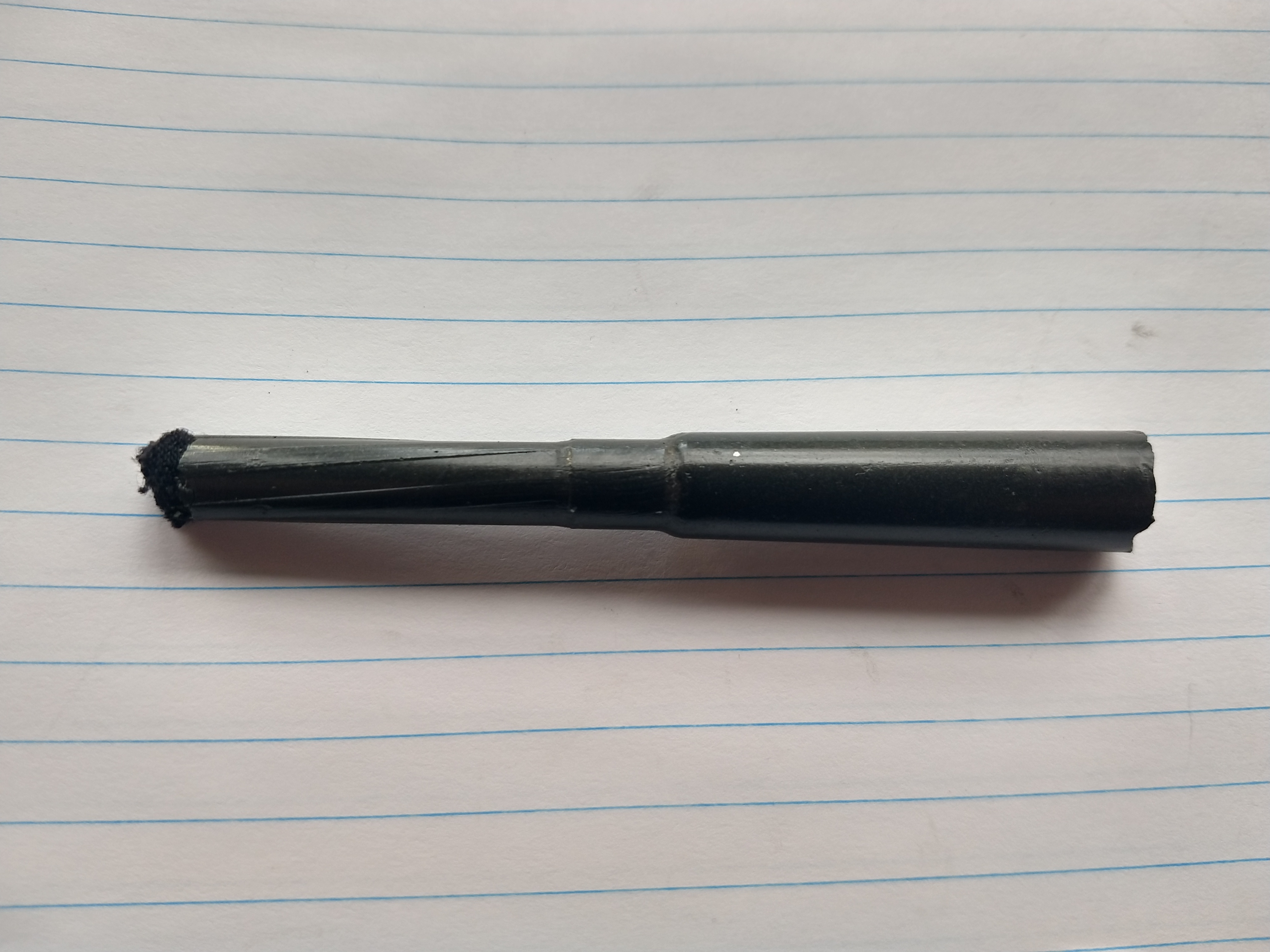

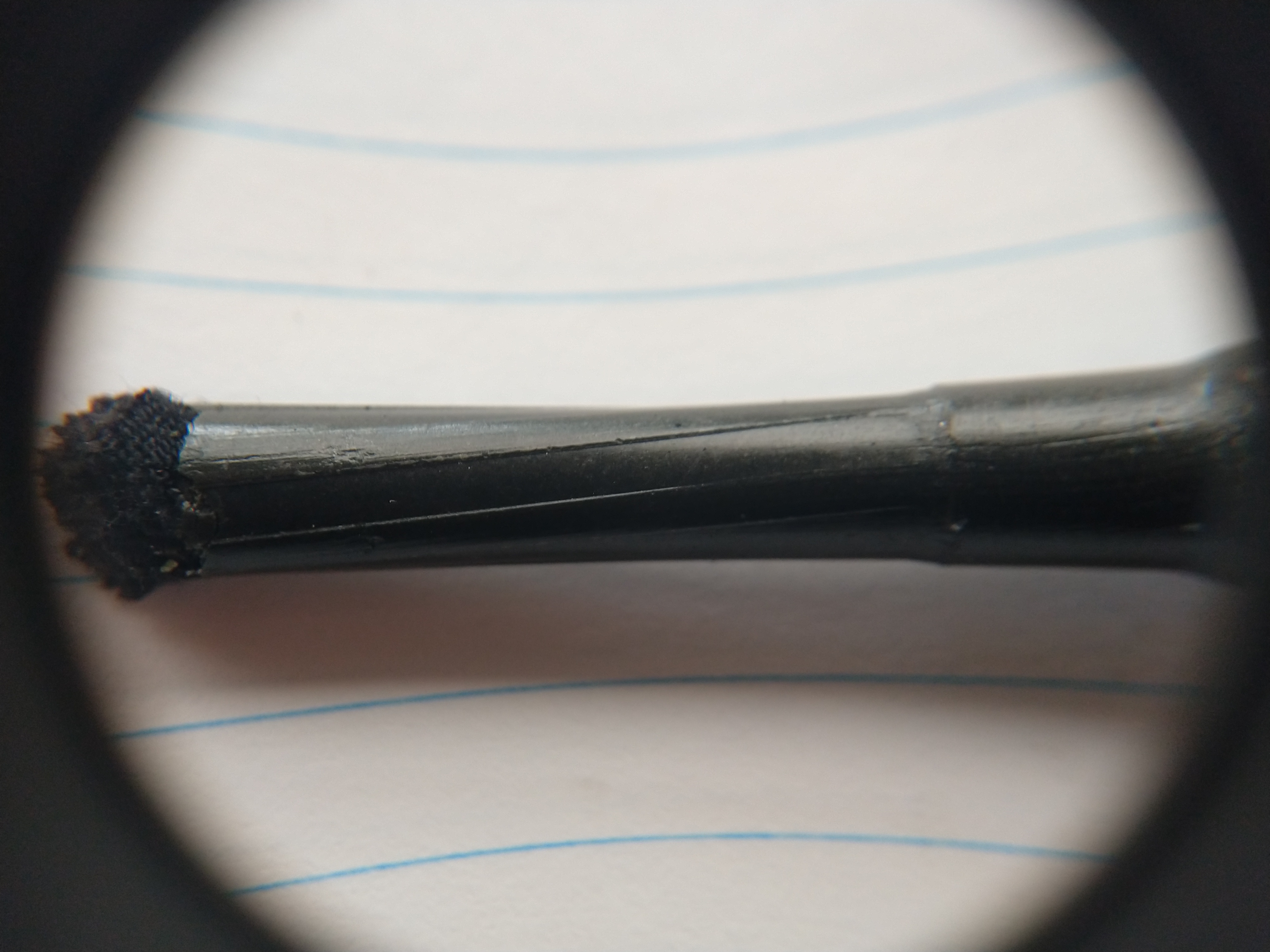

This is what it came out like on the first attempt. I'm pretty happy with the result.

The cast material is very hard, but very brittle. I could get consistent measurements with a micrometer, but it was quite easy to snap in half, if you dropped it on the floor it would certainly shatter.

The sulphur powder I used was from Hortpet and was about $15incl delivery for 1kg, which is way more than I will ever need. The graphite powder was just from Mitre 10 or somewhere like that.

I should warn to do this outside or somewhere well ventilated as if the sulphur catches fire the fumes are apparently quite toxic.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 4 of 4

-

01-01-2022, 09:34 PM #1

Chamber Casting With Sulphur And Graphite

-

-

01-01-2022, 09:39 PM #2

give the excess sulphur to one of your BLACK POWDER shooting buddies.... they sure to put it to good use.

-

01-01-2022, 11:04 PM #3

Fascinating It looks like a great print. I guess you would have to clean things pretty carefully afterward.

-

02-01-2022, 04:05 AM #4

Good job. Congratulations

There is still gunpowder left, the Grim Reaper can wait.

Similar Threads

-

Source of shot for neck sizing graphite lube

By davetapson in forum Reloading and BallisticsReplies: 8Last Post: 17-06-2021, 07:44 PM -

Any one seating bullets using a graphite powder?

By Tim Dicko in forum Reloading and BallisticsReplies: 27Last Post: 06-01-2021, 12:23 PM -

Graphite wearing barrels

By johnd in forum Reloading and BallisticsReplies: 11Last Post: 05-01-2021, 10:56 AM -

Chamber casting material ?

By akaroa1 in forum Projects and Home BuildsReplies: 6Last Post: 25-11-2018, 12:14 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

8Likes

8Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks