Interesting video.

Whilst I appreciate that these measurements do not necessarily determine how well the ammo shoots, I do feel that it gives some validation to how well the dies are manufactured.

What would be more interesting is to compare the internal dimensions of the dies. Especially when it comes to the belted magnum dies, each manufacturer seems to have their own ideas as to what is an ideal amount of sizing (Redding knows what they are doing!)

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 13 of 13

-

19-04-2025, 09:04 PM #1Member

- Join Date

- Feb 2020

- Location

- Scotland

- Posts

- 1,319

Do expensive dies make better ammunition?

Do expensive dies make better ammunition?

-

-

19-04-2025, 11:04 PM #2Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 6,008

Quite interesting, my testing is not quite so technical I think - I was just comparing runout of the finished product off the three types of dies I have on hand for .308W. What I came up with was the Redding Type S was very close to no runout to the limit of the RCBS case master gauge - this has limitations with the design but is useful as a comparison and a qc check. I used the bullet and the case neck, as well as the shoulder as my test points.

The Lee set was pretty close to the Hornady but neither was as straight as the Redding. All were well within useful specs, and the factory ammo I checked was Win Powerpoint and ADI F4 and they were roughly the same as the Lee and Hornady assembled rounds.

What I put that down to, is the ability with the Type S dies to ditch the expander ball and set the neck sizing bushing up to float in the die. This avoids the pull back on the case neck as the round is pulled out of the die and my feeling is that the dies with expander balls won't ever be as straight as the bushing dies with the expander ball removed provided that the case that you are sticking into the die starts off straight.

The other thing I found, is that the Redding dies have by far the lowest force required on the press handle, the Lee was next and the Hornady were bloody shocking for press forces. I could not work out why, as the air relief hole was clear, the inside of the dies were clean as could be, cases were cleaned, lubed etc and everything was right and not fouling as far as I could tell but I tore two rims off the milsurp LC brass I was resizing and the entire job was a pest. I was literally bending the linkages and handle on the dies to cycle the thing through. I've relegated the Hornady set to subsonic .308 loads just so I have the dies permanently set up for that job and I'm not having to swap in and out. Plus the cases don't require so much resizing...

-

19-04-2025, 11:09 PM #3Member

- Join Date

- Jun 2023

- Location

- waimakau

- Posts

- 4,413

I did a comparison years ago with lee loader loaded ammo vs the same ammo done in a press. This was in a hunting rifle the ammo shot the same

-

19-04-2025, 11:51 PM #4Member

- Join Date

- May 2022

- Location

- tauranga

- Posts

- 593

Upgrading to 1 Redding dies for the 7mm prc really helped getting the web diameter resized consistently with ADG brass. I started looking into it after a Hornady FL die cracked.

ADG is launching some even thicker die: 1 1/4 die to help with that

-

Yesterday, 12:04 AM #5Member

- Join Date

- Mar 2012

- Location

- Hastings

- Posts

- 2,893

-

Yesterday, 12:47 AM #6Walking my rifle

- Join Date

- Dec 2015

- Location

- Hamilton

- Posts

- 1,332

For the vast majority of us the answer is no. If you are a Br or F class shooter with grrat skill and a properly sorted rifle you might notice something.

-

Yesterday, 12:48 AM #7Walking my rifle

- Join Date

- Dec 2015

- Location

- Hamilton

- Posts

- 1,332

I dont measure runout anymore, but id go as far as saying that runout as well as CBTO variances is less with my lee dies as opposed to my redding and hornady ones.

-

Yesterday, 09:39 AM #8Member

- Join Date

- Jun 2023

- Location

- waimakau

- Posts

- 4,413

Ive done a small test on run out as well. It was that bad you could see it. Ammo still shot how it was supposed to

-

Yesterday, 09:43 AM #9Member

- Join Date

- Jun 2023

- Location

- waimakau

- Posts

- 4,413

-

Yesterday, 09:45 AM #10Member

- Join Date

- Jun 2023

- Location

- waimakau

- Posts

- 4,413

I dont own fancy dies just lee and hornady mainly, prefer the lee dies over hornady

-

Yesterday, 10:14 AM #11Member

- Join Date

- Jan 2025

- Location

- just here , at present

- Posts

- 111

attention to detail with weighing and technique is more important to me than brand of die

too old to die young

-

Yesterday, 10:30 AM #12Member

- Join Date

- Feb 2016

- Location

- Marlborough

- Posts

- 1,169

I just use Lee gear for my reloading. Measured runout a couple of times compared to mates ammo done on all the flash gear. All near as dam all the same as in frig all. When my eye plays ball I hold my own at NZNRA shooting out to 900 yards and animals don’t give a toss. Loads ammo good enough for me but I don’t get too serious about it.

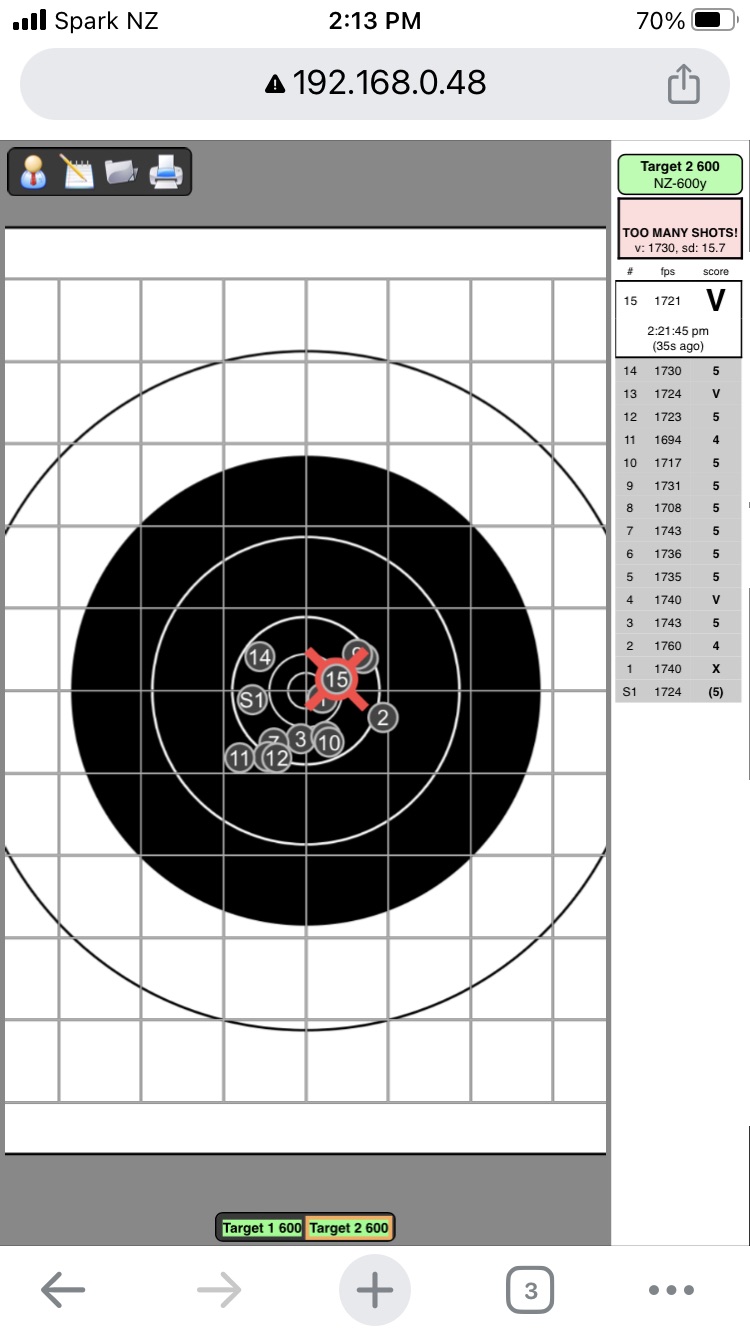

Yesterday @ 600 yds in pouring rain holding off for wind.

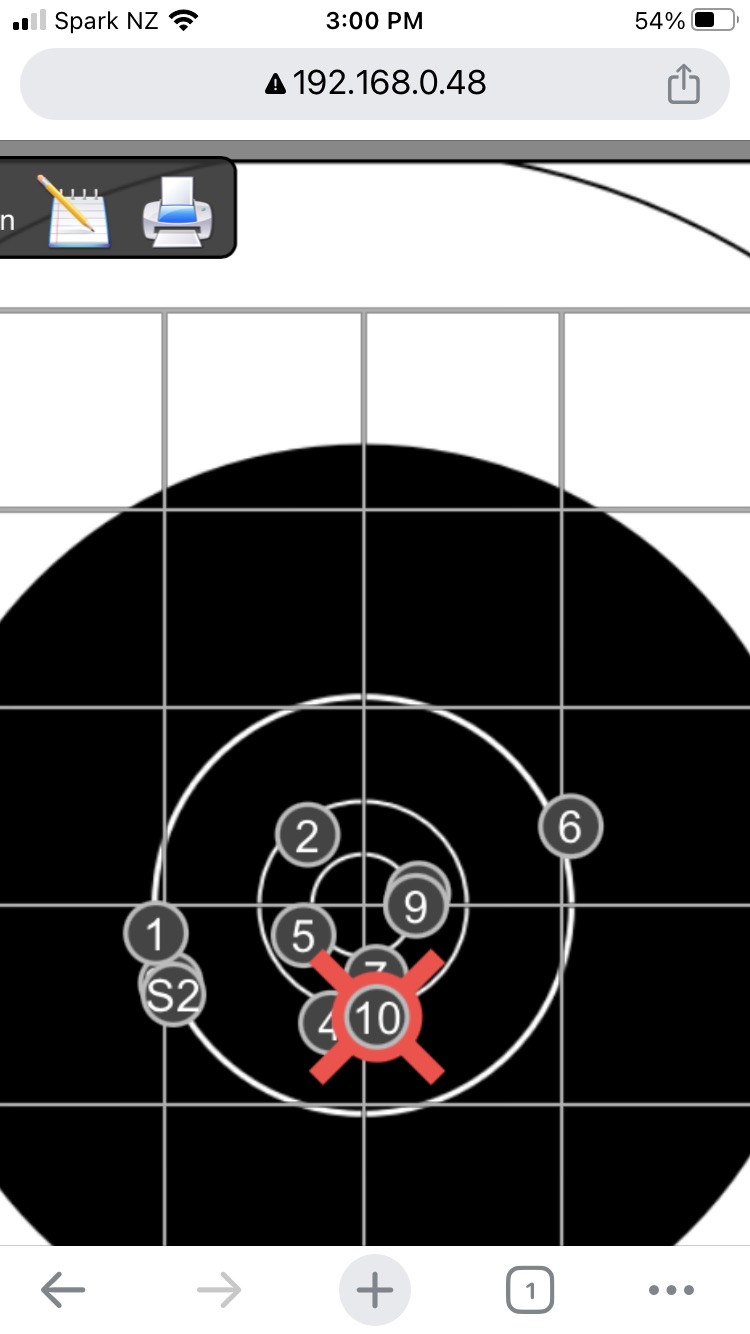

Last week @ 900 yds rear fishtail winds. Again no dialing between shots, just holding off for wind.

-

Yesterday, 03:33 PM #13Member

- Join Date

- Apr 2025

- Location

- Hamilton

- Posts

- 16

I started reloading using very simple Super Simplex 5/8 dies and press. They neck size only. Accuracy for hunting was fine.

As opportunity arose I got a 7/8 press and started to collect 7/8 dies sets. Still use the Super Simolex gear for priming and for some seating jobs.

As I started to move into the .222 based wildcats I went the Redding S type bushing die route - with a .222 S type die and four bushings I can resize 250 Myra (25-222), 222, 20-222 and 17-222.

I have also picked up some second hand Forster micrometer seating dies. The combination of a bushing die and micrometer seater made a noticeable improvement in accuracy for my .243, less so for others.

I too use plain old Lee collet dies for making up F class round for my Omark .308.

For the majority of hunting using factory rifles a basic die set will do the job. Expensive die sets wont make up for untuned loads, poor bedding, poor rifling/crown or poor shooting technique.

Marcus

Similar Threads

-

Expensive wallabies

By yogi in forum HuntingReplies: 96Last Post: 07-09-2023, 09:28 PM -

Corbin press, dies and everything you need to make 22 bullets.

By akaroa1 in forum Reloading and BallisticsReplies: 10Last Post: 29-06-2017, 07:45 AM -

Why are CZ rifles so expensive in NZ

By Philipo in forum Firearms, Optics and AccessoriesReplies: 19Last Post: 10-10-2013, 10:49 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

10Likes

10Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks