Just loading up some 6.5CM with brand new Peterson brass, necked to 0.001 under projectile dia. and the tips are getting crushed when used in my new L.E. Wilson chamber type seating die...

Any ideas? Just need to fireform the brass maybe?

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 34

-

19-01-2019, 08:08 PM #1

ELD-M Getting Crushed when Seating

Hawkes Bay Rifle Club - http://www.sporty.co.nz/hbrc

-

-

19-01-2019, 08:14 PM #2

dunno if this helps or is even your issue but when I started loading ELDX I had to get the seating die machined out to suit the longer projectile otherwise the tips would hit the end of the die as the shape is different to most other projectiles

-

19-01-2019, 08:41 PM #3

Hmm I don't have a concentricity gauge but visually they still look round. I think the neck tension is just too high, but at 0.001" under it should be sweet. I'll just fire them off tomorrow and see what they do on the second round. Hopefully the brass will soften a bit

Hawkes Bay Rifle Club - http://www.sporty.co.nz/hbrc

-

19-01-2019, 08:47 PM #4Gone but not forgotten

- Join Date

- Dec 2011

- Location

- Kaukapakapa

- Posts

- 448

You can get vld steem for seating dies that suit the longer projectiles that stop that from happening i think hornady or reeding do them as parts

-

19-01-2019, 08:50 PM #5

-

19-01-2019, 09:16 PM #6Gone but not forgotten

- Join Date

- Dec 2011

- Location

- Kaukapakapa

- Posts

- 448

$27 a reloaders for a hornady one and about $35 for reeding one from workshop inovations

-

19-01-2019, 11:35 PM #7

.001 smaller than projectile will make for very tight neck tensions, general guideline is .001 less than loaded round diameter

-

20-01-2019, 08:41 AM #8Banned

- Join Date

- Mar 2016

- Location

- auckland

- Posts

- 2,453

As above...looks like too much force to seat them. I get a faint ring on mine when seating.

I don't have a micrometer to measure so am relying on the dimensions of dies and annealing after 3 or 4 loads to avoid a lack of tension problem.

I don't use neck dies any more..just my preference

-

20-01-2019, 08:43 AM #9

Looks like way too much neck tension to get dents like that

-

20-01-2019, 08:50 AM #10Member

- Join Date

- Mar 2012

- Location

- Christchurch

- Posts

- 1,517

Dip the necks in graphite before seating the bullets. New brass creates more friction than fired brass which has a layer of carbon from the firing process (less friction).

-

20-01-2019, 10:17 AM #11Member

- Join Date

- Aug 2015

- Location

- South

- Posts

- 205

Another part of the solution might be to get a powder funnel with a long drop tube so the powder takes up less of the case and therefore less pressure/crunch when seating.

-

20-01-2019, 11:09 AM #12Member

- Join Date

- Mar 2014

- Location

- New Plymouth

- Posts

- 1,739

The only time I get this is when using compressed loads.

One die I changed to a VDL stem which solved the problem. With my .260 using RL16 I had this problem as they were compressed loads, so I changed to Hodgdon superproformance powder and problem solved and it's a lot less bulkier powder.

Sent from my SM-G920I using Tapatalk

-

20-01-2019, 11:14 AM #13Banned

- Join Date

- Mar 2016

- Location

- auckland

- Posts

- 2,453

I never liked the idea of compressed loads and like ball powder partly for this reason

-

20-01-2019, 02:41 PM #14

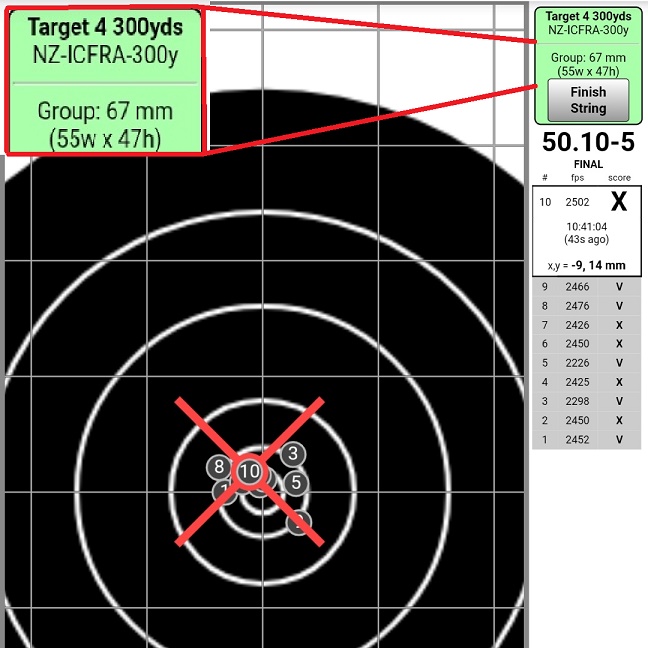

Ok well I went out to the range today. A bit of background, brand new out of the box R700 in 6.5CM, dropped in a KRG Bravo, no trigger work (heavy AF), didn't lap the lugs or anything yet, never even fired a shot. Bore sighted it at 300yds, fired off the first 12 rounds charged with 36.0gr 2208, shot a pretty decent group for zero load dev , better than factory ammo anyway.

Then 2nd string 36.5gr 2208 and shot a 60 with 5 X's

So the crushed jackets can stay as long as they like

Hawkes Bay Rifle Club - http://www.sporty.co.nz/hbrc

Hawkes Bay Rifle Club - http://www.sporty.co.nz/hbrc

-

20-01-2019, 04:37 PM #15Member

- Join Date

- Jul 2012

- Location

- Tauranga

- Posts

- 2,637

You gotta love that.

Similar Threads

-

.22 is misfiring - empty shells are stuck in gun and crushed - any ideas?

By sapphire in forum Firearms, Optics and AccessoriesReplies: 28Last Post: 12-01-2017, 08:50 PM -

Seating 7mm saum with 7mmRM seating die

By Tikka7mm08 in forum Reloading and BallisticsReplies: 22Last Post: 12-12-2015, 03:20 PM -

Wilson seating die

By ebf in forum Reloading and BallisticsReplies: 6Last Post: 02-12-2015, 05:17 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

16Likes

16Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks