A few months back i purchased a T3 708 from @buzzman. He was 70% thru the conversion to a 284 Superpig, long action conversion done, barrel shortened to 17" and threaded.

I had it rechambered to 284 win, there were two options for the reamer, i opted for the tighter neck one (.317), as the standard reamer has a .322 neck, and over the years the 284 brass has become smaller in the neck for some reason, and if run with the .322 neck chamber it over works the brass and you can split necks (annealing would help limit this).

I also spec'd it to be throated for a 162 amax to be seated right out in the neck. Coal of 3.190" base to tip, for maximum powder capacity

Anyways, rifle was rechambered and returned to me - All good. And i set out developing a load, i have another rifle in 284 win, so had an idea where to start etc. I had new 6.5x284 Lapua brass at the ready, and necked it up with my Sinclair expander mandrel then FL die.

When test firing my ladder test, i found excess pressure at below adi book max (which i always find to be quite conservative) and with my far longer OAL compaired to the book spec, i was a bit miffed.

Anyway i settled at 52.5gr of 2209, for 2600 fps. It was very accurate, and was able to hit little gongs at 600 yards all day long at the toby shoot, but i was somewhat disappointed with the velocity and knew something was a bit odd, and parked it away after that, while i played with other things.

Well, i started thinking about it again a couple of nights ago, and started running the verniers over the necks of the brass. Initially it appeared i had enough neck clearance, with a loaded round measuring .313, and a chamber spec on the neck of .317.

However, as i slid the verniers down closer to the shoulder the gremlin was spotted. The very bottom of the neck, just above the shoulder, the neck measured .319!! Ar ha!

It was now that i remember reading somewhere that when you neck a cartridge up, that you form part of the original shoulder, into the bottom of the neck and that due to the shoulder area being slightly thicker material, you now have a thicker lower part of the neck. I assume this is how the 'donuts' start, that people talk about.

Anyway, i have neck turning gear, but haven't really used it other than playing/trying it out. So after setting it up to suit, and after trimming a few cases to the same length, i did a very light turn all the way down and just cut into the shoulder ever so slightly.

After FL sizing again, i loaded up 2 ladder tests, one with the original powder (2209) up to 1 gr over book max, and the other with N560 from 58 -60gr (to shoot if the 2209 test went well.

Well back to the range this morning to test fire it, and see if i sorted the problem.

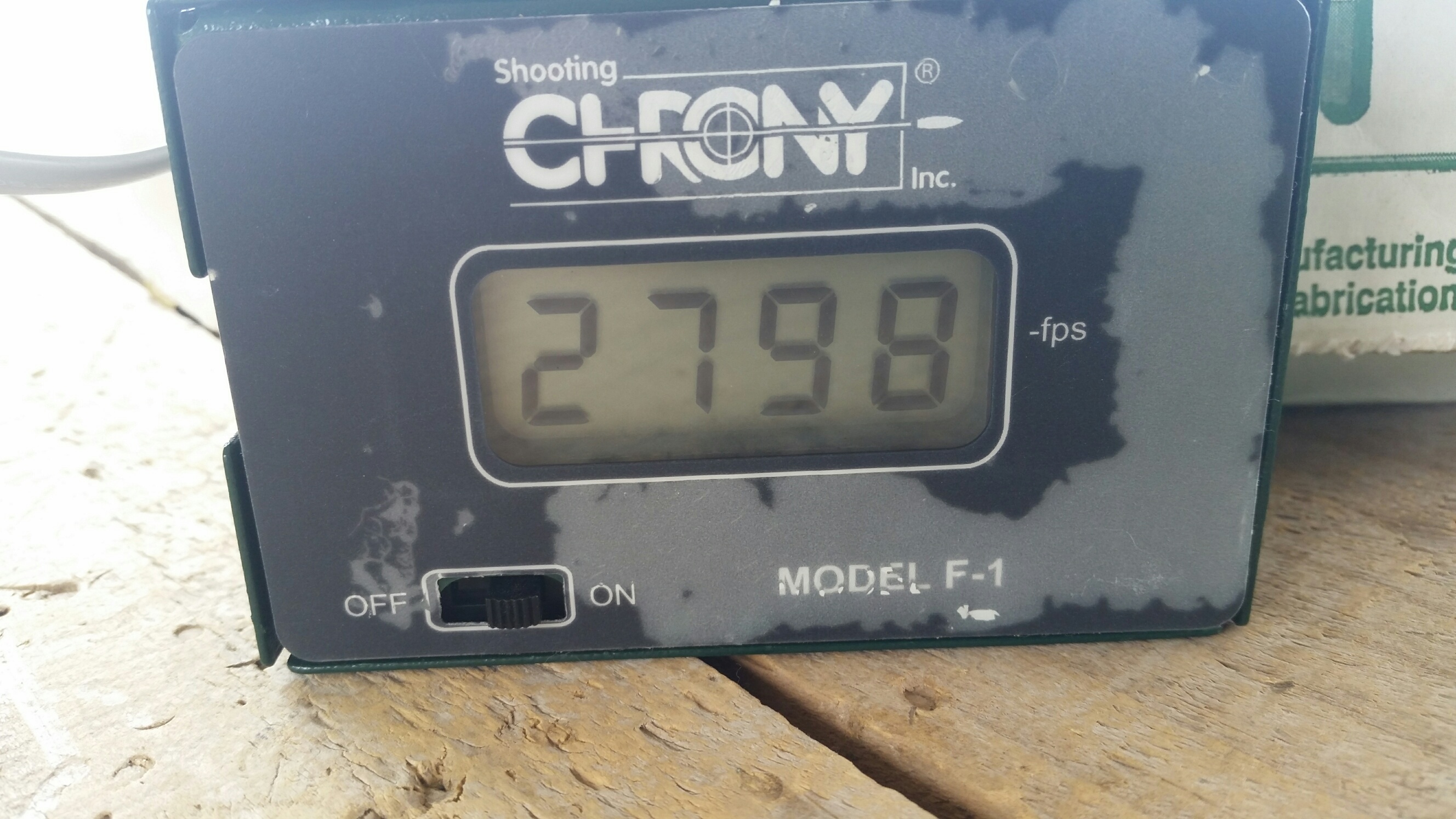

My ladder started at 52.5gr, my previous max no excess pressure load, and i worked my way up to 54.5gr (1gr over book max) I didnt see any excess pressure signs at all, and 54.5gr gave me 2800 fps, 200 fps gain on before.

So the Gremlin's been found, and the potential of the short 17" 284 has been released. The Amax at 2800 fps holds over 1,000 ft-lbs energy to 900 yards (600m Altitude)

I continued to shoot the N560 ladder and got heavy bolt and ejector mark at 60 gr for 2830 fps, so nothing to be gained with using that very expensive powder.

For people that use the standard spec 284 reamer, they wont see this problem (well not initially anyway), but you really need to neck turn if necking up the 6.5x284 brass (i assume necking up any cartridge actually).

It should be a pretty handy and useful rifle now, good for hunting with the young kids being suppressed, total length incl suppressor equivalent to a 21" barrel. Short enough to make bush bashing no drama, and enough poke to slay em across a gully at 600 yards. A true allrounder, as my mate @VTR suggested, i could probably sell all my other rifles now.......but i wont ;-)

It turned out alright after all, happy camper.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 33

-

18-01-2017, 05:07 PM #1Member

- Join Date

- Jul 2012

- Location

- Napier, Hawkes Bay

- Posts

- 4,460

Finding the Gremlin - 284 win rechamber

Last edited by GWH; 18-01-2017 at 05:26 PM.

-

-

18-01-2017, 05:26 PM #2Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,451

Nice. What does it group like at the new speed?

-

18-01-2017, 05:33 PM #3Member

- Join Date

- Jul 2012

- Location

- Napier, Hawkes Bay

- Posts

- 4,460

-

18-01-2017, 05:45 PM #4

Interesting report.

I nearly went down the same track (284win T3 conversion) but instead decided to take the boring route of re barrelling my 300WM to 7mmRM. I got a new barrel for the right price and the barrel swap is costing $50. Hopefully this conversion won't cause any head aches (except to the game).Experience. What you get just after you needed it.

-

18-01-2017, 05:57 PM #5

Yeap donuts get worse going up to 30cal.

"Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

-

18-01-2017, 06:05 PM #6Member

- Join Date

- Jul 2012

- Location

- Napier, Hawkes Bay

- Posts

- 4,460

-

18-01-2017, 07:54 PM #7

@Kiwi Greg sorted my brass first time round and I am pretty sure he inside reamed?

"Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

-

18-01-2017, 08:48 PM #8

Very interesting.

Sent from my iPad using TapatalkDan M

-

19-01-2017, 07:55 AM #9

-

19-01-2017, 08:56 AM #10Member

- Join Date

- Jul 2012

- Location

- Napier, Hawkes Bay

- Posts

- 4,460

-

19-01-2017, 09:34 AM #11

I havn't had that problem thank goodness as I'm using factory winchester brass. I'm about to load some 150gn Sieraa game Kings to see how they go.

-

19-01-2017, 10:02 AM #12Member

- Join Date

- Jul 2012

- Location

- Napier, Hawkes Bay

- Posts

- 4,460

-

19-01-2017, 10:50 AM #13

I've got some 2209 to try with them as I've been using RL17 previously.

Sent from my SM-G900I using Tapatalk

-

19-01-2017, 12:06 PM #14Member

- Join Date

- Jul 2012

- Location

- Napier, Hawkes Bay

- Posts

- 4,460

-

19-01-2017, 12:39 PM #15

thanks for sharing GWH - damn handy to know. Will have to check my 284 brass more closely to see if similar is happening.

Dumb question - is the photo with red line pre or post neck turn ?

Similar Threads

-

Bent 308 barrel - what would you rechamber to?

By Nickoli in forum Firearms, Optics and AccessoriesReplies: 21Last Post: 12-12-2016, 11:49 PM -

finding groper etc?

By silentscope in forum FishingReplies: 11Last Post: 01-11-2014, 09:36 PM -

help finding a new camra/video

By dale in forum Photography and VideoReplies: 12Last Post: 15-10-2014, 06:51 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

49Likes

49Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks