Agreed. When the annealing "fad" appeared I decided unless I could do it consistantly case to case I wouldn't bother. I never had a need to do it due to split necks. Since gone down first the Benchsource path followed by the AM$.

My last build, 308 FTR and my 6.5x47L I get single figure ES and stunning accuracy, especially the 6.5x47.

My 7.5x55 Swiss I get around 30 fps ES but still great accuracy given the type of rifle.

Wide ES doesn't necessarily mean poor accuracy at close ranges. It's more telling at 1000 yds and on.

Conversely I've had loads with single figure ES that I've scrapped as they didn't perform accuracy wise.

I no longer neck turn except for my tight neck 6.5AI. All my recent builds are no neck turn chambers.

I haven't seen much difference in quality between Peterson and Lapua. Both have the 1/2 thou seam in the neck. The same seam I suspect runs the full case length. I used to get anal and turn this out. It doesn't affect my runout which is <1 thou usually. The Peterson 308 brass is currently parked up as it has reduced capacity over the Lapua. I won't bother getting any more Peterson.

Since AMP I have changed my loading technique. I anneal every firing. FLS using a Forster die (absolutely top quality) with expander removed, and the expand using a 21st Century expander. This process has seen my runout and ES drop very favourably. Previously I neck sized using Redding Comp Bushing dies. My runout with these was not consistant/frustrating. The worst creator of runout I found was Redding Body dies. They just don't support the neck when sizing.

Chasing runout I have been down the Redding Comp dies and Wilson inline dies path. Now that I'm Forster FLSing and then expanding I'm finally in control of neck tension and runout.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 31 to 45 of 76

Thread: Getting ES down with 223

-

08-07-2021, 10:26 AM #31

-

-

08-07-2021, 10:36 AM #32

Just a further note on runout. When I shot fullbore my reloads were sorted into good and "bad" runout. Good for the harder ranges and comps, "bad" well, they tended to pile up to the point I had to use them. My centre count when firing the "bad"(and I was a reasonable shot) was on average unchanged over the good stuff.

Reinforced the point that @10-Ring makes about the shooting conditions. Fullbore is off the elbows and dealing wind. As long as the ammo hasn't got bad vertical the wind alone negates the difference between superb reloads and slightly less perfect stuff. Obviously though you want the foundation of your shooting to be on great ammo and that just leaves the shooter to deal with the elements.

-

08-07-2021, 10:37 AM #33

@Pommy, what SD are you getting ?

It would also help to know how many shots in a typical string when you are measuring.

ES only looks at the outer edges of a series, it is a poor measure.

In my experience the major factors affecting low SD:

- Annealing / Neck tension

- Flash holes

- Primer selectionViva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

08-07-2021, 11:21 AM #34

Hey Zimmer

Always fun talking to you about reloading.

Always fun talking to you about reloading.

I'm curious about your experience with the Redding body dies. That's what I've been using for years. Do you think the body die somehow introduced runout on the neck or projectile ? I am not sure how that would happen, unless the die itself was cocked at an angle, and the whole case body got skewed... What neck die did you follow the body step with ? My sequence is Redding body, followed by Lee collet neck die, both using Forster cross bolt lock rings.Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

08-07-2021, 11:24 AM #35

You're right. I take more notice of SD but in my best loadings get single figures on both. And yes, you can delude yourself with small sample size eg the classic cherry picked 3 shot group.

A bit on primer flash holes (using quality brass) I give them an internal debur when new and that's it.

Primer pockets depths - I used to uniform. Don't bother with quality brass.

Norma brass. I imported Norma 284W brass from the States when it was available a few years ago. Norma did a special run for one Yankee company. I did accurate measurements of the flash holes which are drilled. The flash holes are actually shaped like a vortex ie tapered and open out as they exit into the case. Maybe a bit of carefull thinking gone into this.

Don't know if the crop of Norma 284W that was recently available here had the same feature.

-

08-07-2021, 11:47 AM #36

I checked fired cases out of the chamber and they had zero runout. Sized in the body die (not just my 308) and there would be a few thou runout. Not much but there. Measured with a 21st Century gauge both on the outside of the neck and inside. Following up with Redding Comp bushing and runout not removed. Tried leaving the bushing floating and also locked down and no difference.

The Forster (or and quality brand) FLSing die totally supports all aspects of the case, the neck cannot move.

Lee Collet dies. Love em. Used up to the time I changed to FLSing everytime. Never had runout issues using the Lee.

Although I still use them on my 223.

Yep, changed to Forster lock rings years ago. Probably didn't have the gear back then to measure improvements but did it as a matter of course to hopefully remove a variable. Like a lot of things, a little bit of this and a little bit of that can gave a cumulative effect so it's a matter of working thru them.

One thing I've noticed, and it's probably spring back, hopefully minimized by annealing is that the neck can have a slight taper front to back on it after sizing. Not helped also hy the sometimes poor quality of bushings. Although seating the projectile should expand the taper uniformly it doesn't always seem to be the case. Runout at the point on the projectile just outside the case neck can be zero whilst at the projectile tip can be lots.

I have honed my seating stems to individual projectiles eg the Juggenauts and this mostly eliminates this.

-

08-07-2021, 12:36 PM #37Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 3,193

Greeting Zimmer,

A most interesting post. I had read that ES was a poor indicator of accuracy at shorter ranges but this and your following post has put more meat on those bones. I guess it comes down from what you can do in handloading to what you need to do to achieve the results that you are after or require. I can't remember ever shooting beyond 300 metres on the range and definitely not in the field, neither of which looks likely to change in the future.

That said, if going through all of the possible steps fills the handloaders heart with joy then why not. There will be no argument from me.

Regards Grandpamac.

-

09-07-2021, 01:14 AM #38Member

- Join Date

- Aug 2018

- Location

- Christchurch

- Posts

- 1,751

Rigto, data time...

55gn Nosler Varmageddon (tipped, flat base)

Overall length of 2.350" (Forster seating die)

25.0gn AR2219 (individually weighed out on an A&D)

Federal GM205M primers

Three batches of brass, FL sized with a Forster die, fired stuff annealed with an AMP machine

Starline (brand new, flash holes left alone), average length 1.749" +/- 0.001"

Starline (fireformed, flash holes uniformed), all trimmed to 1.750"

Lapua (fireformed), also trimmed

Everything fired past a labradar.

Starline (new)

3311

3278

3245

3254

3274

3266

3240

3275

3267

3287

ES 71, SD 20.8, AVG 3270

Starline (fireformed)

3264

3295

3249

3319

3301

3259

3286

3287

3277

3279

ES 70, SD 20.9, AVG 3282

Lapua (fireformed)

3308

3287

3301

3311 (at this point I'm thinking "f$#k!, you gits better not be right")

3274

3328

3237 (aha!)

3248

3300

3316

ES 91, SD 29.7, AVG 3291

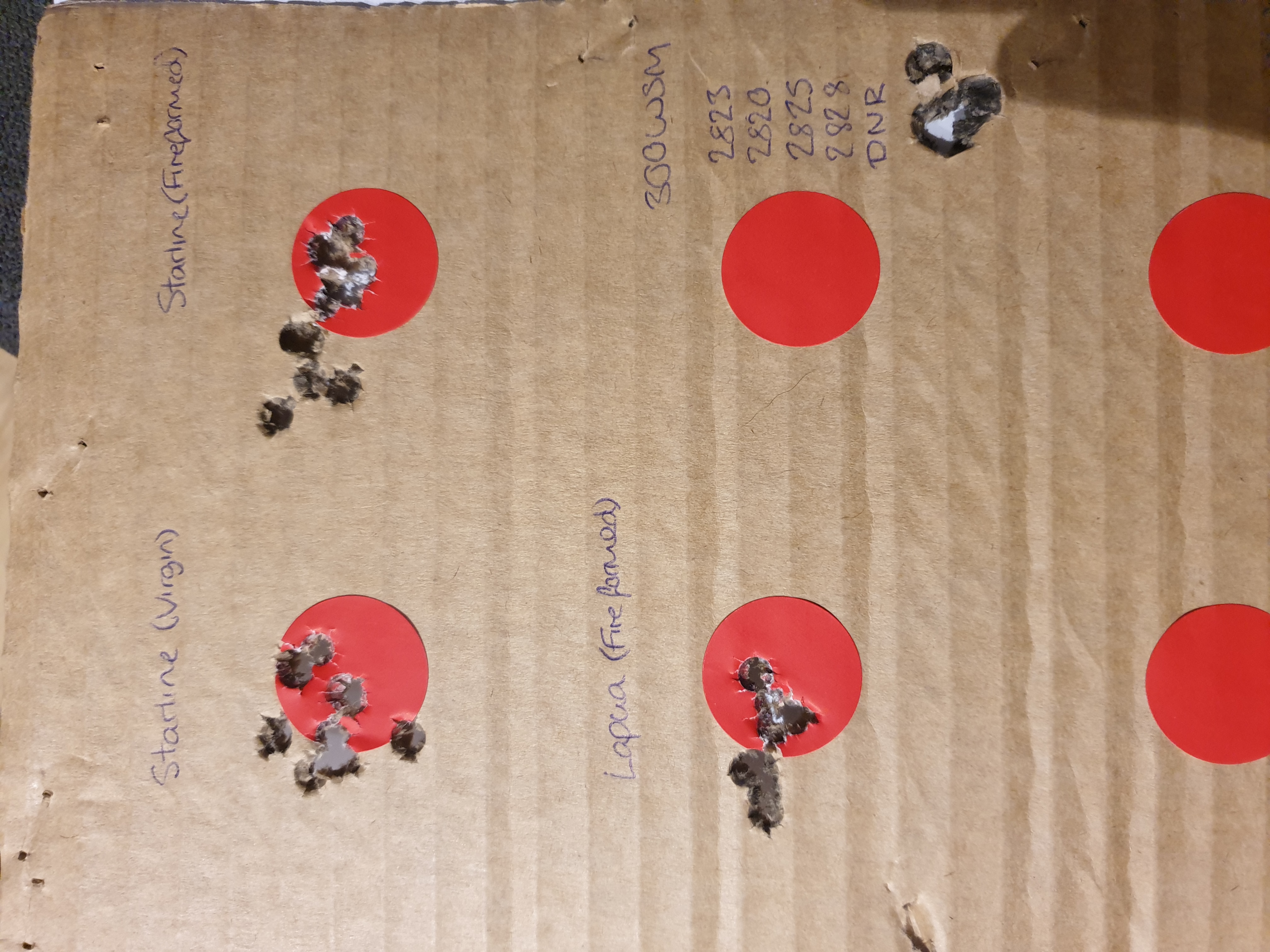

Bonus five rounds of 178 ELD-X hand loads from my 300 WSM to exhonorate myself (only four readings - the last didn't register since the muzzle brake and the chrono aren't friends)

2823

2820

2825

2828

----

ES 8, SD 3.4, AVG 2824

Picture of the 100m target...

The 223 action is not bedded into the stock very nicely which I think is contributing to the horizontal dispersion. Groups I think could have been better with a bigger badder scope like the VX5 on the WSM, but the Lapua 223 group is undoubtedly better than both Starline groups.

With @Steelisreal as my witness, the above is all accurate.Last edited by Pommy; 09-07-2021 at 01:29 AM.

Resident 6.5 Grendel aficionado.

-

09-07-2021, 01:37 AM #39Member

- Join Date

- Aug 2018

- Location

- Christchurch

- Posts

- 1,751

Neck tension on all rounds felt consistent during seating.

The bullet is quite long as far as 55gn pills go, so it's seated right down to the neck-shoulder junction. Seating further won't get any more grip on it.

Attachment 172202Resident 6.5 Grendel aficionado.

-

09-07-2021, 10:02 AM #40Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 3,193

Greetings Pommy,

That was interesting. You have obviously drawn the obvious conclusions so I won't go over them. From my own .223 rifles I noted a much larger SD than with most of the larger cartridges. This with groups less than half the size of yours with Remington cases. My 7mm Rem SAUM handloads give low ES as does your WSM with similar accuracy. You may wish to consider a different aiming mark. I note that a good part of your 25mm dots are shot out by the end of the string which won't help with aiming. I mostly use the NZDA 50 and 100 metre targets which are a red circle on a white background. Mostly the 50 metre targets are used at 100 metres unless the scope is low power. These allow you to quarter the white circle with your cross hairs with the group forming in the circle. Bedding does seem to be high on your to do list though.

Regards Grandpamac.

-

09-07-2021, 10:47 AM #41Member

- Join Date

- Aug 2018

- Location

- Christchurch

- Posts

- 1,751

The crosshair on the Nikon currently mounted to my 223 is quite thick and pretty much obscures those dots. I used the BDC to aim at the dots below, so blowing out the aiming point was not an issue. The WSM group hopefully demonstrates that I'm not completely useless behind the trigger (rifle is not zeroed for that load). With a beefier scope and a properly bedded rifle, I'd expect those 223 groups to shrink considerably and I understand *why* they are a bit sub-par currently, so that's OK (the two left hand groups are around 0.8" and the right hand group is around 1.2").

For the purposes of this exercise though, I am more concerned with the velocity data. I'd expect that smaller cases like 223 will inevitably have proportionally higher ES/SD than larger cases, as a similar variation in charge weight or case volume is going to be a greater percentage in terms of change on a smaller charge or smaller case - which effects pressure more thus effects velocity more. Even so, the 223 is approx 25gn of powder vs the WSM's 65gn, that's only 2.6x the capacity in the larger case, and charges are accurate to the kernel in both... yet there's 7x the ES/SD in the 223.

I know we are also dealing with higher velocities in the 223 too and that say a 1% ES from 2800ft/s would be 28 vs a 1% ES from 3300ft/s being 33. That still doesn't account for enough. With the 69gn load doing 3120, the ES is 15-20ft/s, so the 223 clearly is capable of it... just these effing 55gn bullets aren't getting the memo.Last edited by Pommy; 09-07-2021 at 10:54 AM.

Resident 6.5 Grendel aficionado.

-

09-07-2021, 11:28 AM #42

If you are getting good ES/SD with 69gr out of the same 223 rifle, could it be something to do with twist rate ?

Have you tried other 55 gr projectiles ?Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

09-07-2021, 11:39 AM #43Member

- Join Date

- Aug 2018

- Location

- Christchurch

- Posts

- 1,751

Yes I've tried 53gn VMax, 50gn Speer TNT's, and 55gn Speer Gold Dots.

In theory the projectile is going to be a little harder to get going down the rifling which might cause a little more of a pressure spike as the bullet spins up, but that would be true of any projectile weight and to my mind should make it easier to get more consistent ignition. How do you think it might negatively effect ES/SD?Resident 6.5 Grendel aficionado.

-

09-07-2021, 12:23 PM #44

Are all the 55gr and lighter projectiles giving you large ES/SD numbers ?

It could be that you are seating the light pills further from the lands, so more time in the freebore giving you inconsistent pressure ? Not something I have a lot of experience with, one of the other guys might have some ideas on this.

I wouldn't expect twist to give you poor ES, more likely poor group sizes. Not like you are using a slow power. I use BM2 for 55/62/69gr in the 223.Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

09-07-2021, 01:30 PM #45Member

- Join Date

- Aug 2018

- Location

- Christchurch

- Posts

- 1,751

Yep, everything's pretty similar. With those Nosler bullets being quite long, seating them out to 2.350" actually gets them pretty close to the rifling.

I am going to try the nylon brush as per the AMP video you linked to. It'll be interesting to see if it follows that more consistent seating force = more consistent neck tention = any change in ES. That's not something I do currently and it's a cheap experiment. For last night's test, the cases all had the necks wiped out with a rag after sizing and trimming - but maybe the brush will clean more thoroughly? Dunno...

I'll try the following with BM2 and Starline brass:

10rds virgin brass (so clean necks), FL sized, wiped

10rds fireformed brass, FL sized, necks wiped

10rds fireformed brass, FL sized, necks brushed

I'll stick with the GM205M primers, so that I'm not changing too many variables.Resident 6.5 Grendel aficionado.

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

73Likes

73Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks