So I've started using a Hornady O.A.L gauge and bullet comparator for my Rem700 .243 loading 95gr berger VLD's and 95gr Hornady SST's

Trying to measure accurately my O.A.L and using the bullet comparator to give a consistent measurement to the bullet Ogive instead of the tip of the bullet

running into a couple issues

1st- when measuring the OAL im getting 2 different results...

a- 3.160" with small amount of pressure on the rod and using a dowl down the muzzle to move the bullet back from the lands (berger vld 95gr)

b- 3.345" with same pressure but this time I lift the Gauge rod that holds the case slightly and once again using the dowl to move the bullet on and off the lands a few time before taking the measurement.

this is similar of the hornady SSt rounds as well

So I thought I would check my factory Remington 100gr core-lokt using the bullet comapator

Result = 3.245" to Ogive

So I then removed the core lokt bullet and used it in the OAL gauge once again 2 results

a- 3.290" same method as last (a.) (so thats 0.045" difference)

b. 3.375" using same method as previous (b.)

So whats going on? which method is right? or do I have a problem with my rifle e.g its throated, exceess freebore due to wear or due to a manufacture thing

-My rifle is not new it has fired a fair amount of rounds and last time I had it at the gun smith he said the barrel had done over half its wear life but was fine. and I dont do alot of shooting

-when I use remington 100gr corelokt factory I get irregular results batch to batch some run through 1" @ 100m others 2" @ 100m chrony reads 2650fps

-I was running the berger 95gr using AR2209 41 & 42gr seated at 3.140" (0.02 back from 3.160") in hornady brass necksized had that grouping sub 1" @ 100m @ 2770fps

however shot all over the place at 200m for some reason but that may have been me.

-I was chatting to a local reloading expert (who does load development) and he looked at my Bergers and said they were seated back too far and to recheck my OAL, so thats how I got onto checking if I was taking the right measurement with the OAL gauge thus running into this problem which has me stumped as its a huge difference between the two figures...?

I have included a photo

from far left

1-berger vld 95gr at 3.140"

2- berger vld 95gr at 3.290" (same as factory corelokt just for comparason)

3- Factory rem 100gr corelokt at 3.290"

4- berger 95gr at 3.325 (0.02" back from the 3.345" reading)

all rounds fit in the mag and cycled fine, bolt closed without stiffness or excess pressure (havent fired any of these as I just seated them in empty cases to compare them)

Im sticking with factory for now until I sort this out properly

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 17

-

31-03-2014, 01:23 PM #1Member

- Join Date

- Aug 2013

- Location

- Manawatu

- Posts

- 96

HELP OAL gauge and bullet comparator problem...

-

-

31-03-2014, 02:21 PM #2Member

- Join Date

- Aug 2013

- Location

- Manawatu

- Posts

- 96

sorry just realised the two rounds in the photo are seated at 3.245" not 3.290" (not a war stopper I know)

once again any advise will be appreciated...Cheers

-

31-03-2014, 02:30 PM #3

Why are you pushing the bullet back down with the dowel. I just push the projectile gently forward until it stops.

-

31-03-2014, 02:38 PM #4

Not sure what you're actually wanting to achieve, a bunch of measurements that look right, or a rifle that shoots as well as can be expected. If the latter, go back to your Berger 95 with AR2209 load. Any hunting rifle shooting sub MOA is good to go. If you want a tack driver worthy of your mathematics, buy one.

10MRT shooters do it 60 times, in two directions and at two speeds.

-

31-03-2014, 04:02 PM #5Fulla

- Join Date

- May 2012

- Location

- Cni

- Posts

- 1,660

at a guess I would say your longest measurement is correct. if your just putting light pressure on it, it wont really go too far in. (of course there is jamming a projectile but a trigger pull weight push on the oal gauge shouldn't really jam) using the dowl is normal.

take that longest measurement and minus ten thou and make a dummy round. chamber it then look for marks on the projectile, if there arnt any you are just off the lands, so your ten thou should be about right. if you want to mark the projectile with the soot from a flame or a felt pen it might make it easier to see the marks from the lands if its touching.

at the end of the day your starting oal isn't too important, if you cock up your measurement and its say... 6 thou jump instead of the ten thou jump you think you have... as long as you do have jump as its a hunting round that's ok. and you may fine tune later with seating depth and end up with more jump anyway.

oh... take magazine length into consideration too, you may not be able to seat out that far anyway.

hope that helps.

-

31-03-2014, 05:37 PM #6Member

- Join Date

- Aug 2013

- Location

- Manawatu

- Posts

- 96

thanks bully that helps will try the soot/pen trick tonight to see if its touching the lands on a dummy round at the longer measurement

-

31-03-2014, 05:41 PM #7Member

- Join Date

- Aug 2013

- Location

- Manawatu

- Posts

- 96

-

31-03-2014, 05:50 PM #8Member

- Join Date

- Aug 2013

- Location

- Manawatu

- Posts

- 96

my concern was I was getting two vastly different measurements with the same projectile ( difference of 0.185" ) and I should only be able to FORCE the projectile 0.025" into the lands so something else was going on... was just wondering if anyone else has had the same issue? and yea the load I had did work great.

-

01-04-2014, 05:23 AM #9

partly neck size a case then use the seating die to start the projectile into the case neck put it in the chamber of rifle and close the bolt on it to push the projectile further in remove and measure then set your seating die on it and adjust till you get the required distance between ogive and lands of rifle using your comparator guage.

RULE 4: IDENTIFY YOUR TARGET BEYOND ALL DOUBT

To be a Human is to be an Alien, ask the animals, We invade this world and we are killing it, we are destroying the earth and nobody gives a fuck except for the animals

.

-

01-04-2014, 08:08 AM #10

Hi,

I've been using the Horny OAL gauge since I started reloading, and I have never once got a consistent CBTO measurement. The way I measure my lands now is to make 6 measurements. Of the six there is invariably one measurement thats long than the others by 10-20 thou (0.02") I just use the rest, and take the second Shortest:

Example (223 Rem) CBTO for Hornady Vmax 40's (measured)

1. 1.885"

2. 1.886"

3. 1.884"

4. 1.887"

5. 1.894"

6. 1.886"

In this case I used 1.885" as my lands measurement. The "Wildcard" long seater was 1.893 (Number 5, above)

The following method is a(nother) good way to find the lands - if you've got the right rifle for it (Doesnt work so well on my tikka due to the way the ejectors set up)

Bullet seating depth Method

Also, would suggest you talk to @ebf .. he's also currently having issues getting Berger VLD's to group out of his 308 .. and he did mention they are touchy regarding seating depth.

Finally (whew) keep us informed of your progress ... I'm doing a load soon for my 243 using Targex 95's (which are a Berger VLD Jacket)

regards

Tim

-

01-04-2014, 08:15 AM #11

One more thing .. when I'm testing my loads I ALWAYS use a bipod and rear bag. I KNOW this is not how you shoot in the bush, but you're testing the Projectile and load here, not your shooting ability.

You need to level the playing field as much as possible to give the better loads their chance to shine ..

Sorry if this is stating the obvious (or if you were already using a bag)

Regards

T

-

01-04-2014, 02:20 PM #12

First of all, check your vernier to see that it is consistent, maybe it needs fresh batteries ?

Second, use a single projectile, and repeat the measurements several times.

You have to apply consistent pressure on the rod, either by developing a feel for the same force, or using a (light) weight on a string to act as a pendulum hammer type setup. I just tap the back of the rod with my finger until I feel the projectile engaging the lands. If you get marks on the projectile you are using too mush force.

As far as seating the VLD's you may need to drill out the stem in your seating die to ensure that it makes contact with the ogive rather than the projectile tip.Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

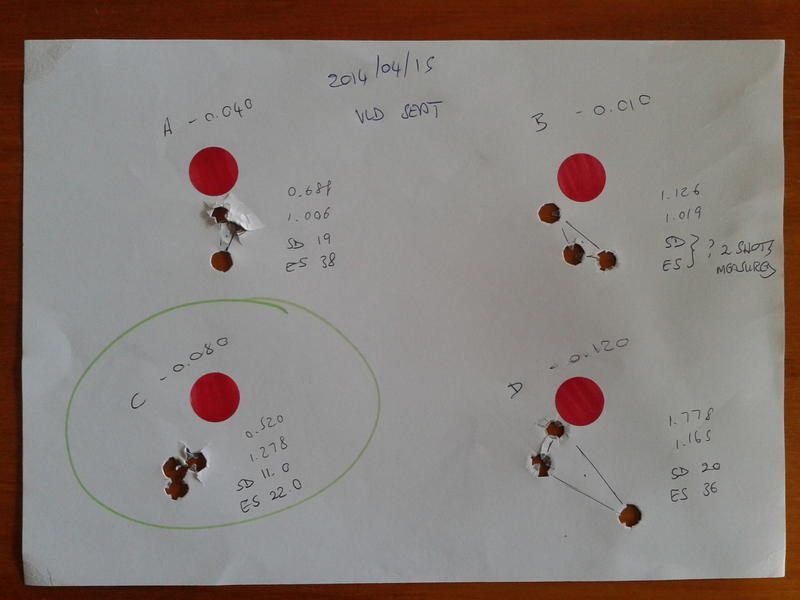

09-04-2014, 02:27 PM #13

Interesting comparison of the seating depth differences with the VLDs

From L to R, Speer 150 BTSP, Lapua Scenar 155, Berger VLD 155, all seated 0.0010 back from lands...

Got a new batch of VLDs loaded : 0.010, 0.040, 0.080 and 0.120 off the lands, hopefully testing later this week.Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

09-04-2014, 05:30 PM #14

I had similar problems a long time ago, fixed it by buying the seating stem made for vld projectiles like the bergers. I think most die manufacturers have them available now

Muzzleloaders have big balls

-

15-04-2014, 02:30 PM #15

Got some time to do more testing on the VLDs this morning, think I have cracked it

Berger should consider renaming these bullets to VUS (Very Unusual Seating), haha. Found an article on the net saying you should try 0.010, 0.040, 0.080 and 0.120 off the lands.

This is the result:

So it looks like the secret formula for my 788 is 80 thou off the lands. Getting some nice low SD numbers as well, so pretty happy with this.Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

Similar Threads

-

308 comparator & case gauge measurements

By ebf in forum Reloading and BallisticsReplies: 1Last Post: 09-08-2013, 10:54 PM -

12 Gauge ammo help

By Toby in forum ShotgunningReplies: 12Last Post: 05-04-2013, 03:50 PM -

Dog with a little problem

By Chris in forum DogsReplies: 18Last Post: 14-05-2012, 08:15 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

1Likes

1Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks