This post is related to belted magnums in particular but can apply to other rifle brass. My experiment pertains to 30cal. I've found with 7mm and 308 belted magnums that it is common to only get around 4-5 reloads before incipient head seperation starts showing up. This thinning of the case just above the web can lead to dangerous case failures. In regular cartidges like 308 win one might expect 10-20 reloads before the problem occurs and these cases typically headspace of the shoulder rather than a belt. I set my dies to give 2-3 thou headspace where possible bit with belted magnums the headspace is fixed, off the belt and it is common that the chamber dimensions are longer than the case shoulder area, sometimes by more than 10 thou". The problem initiates from the first firing because during ignition the internal pressures jam the sides of the case against the chamber wall at the same time as the firing pin forces the round hard into the belt. Simutaneously the shoulder is blown tight against the sides of the shoulder junction in the chamber and the only unjammed part of the cartridge is the rear portion near the belt. This stretches longitudinally creating beginnings of thinning of the brass in that area.

Most reloaders try to headspace off the shoulder for subsequent reloading but the damage is already started by the first firing unless you have a very tight dimensioned chamber exactly to match your virgin brass.

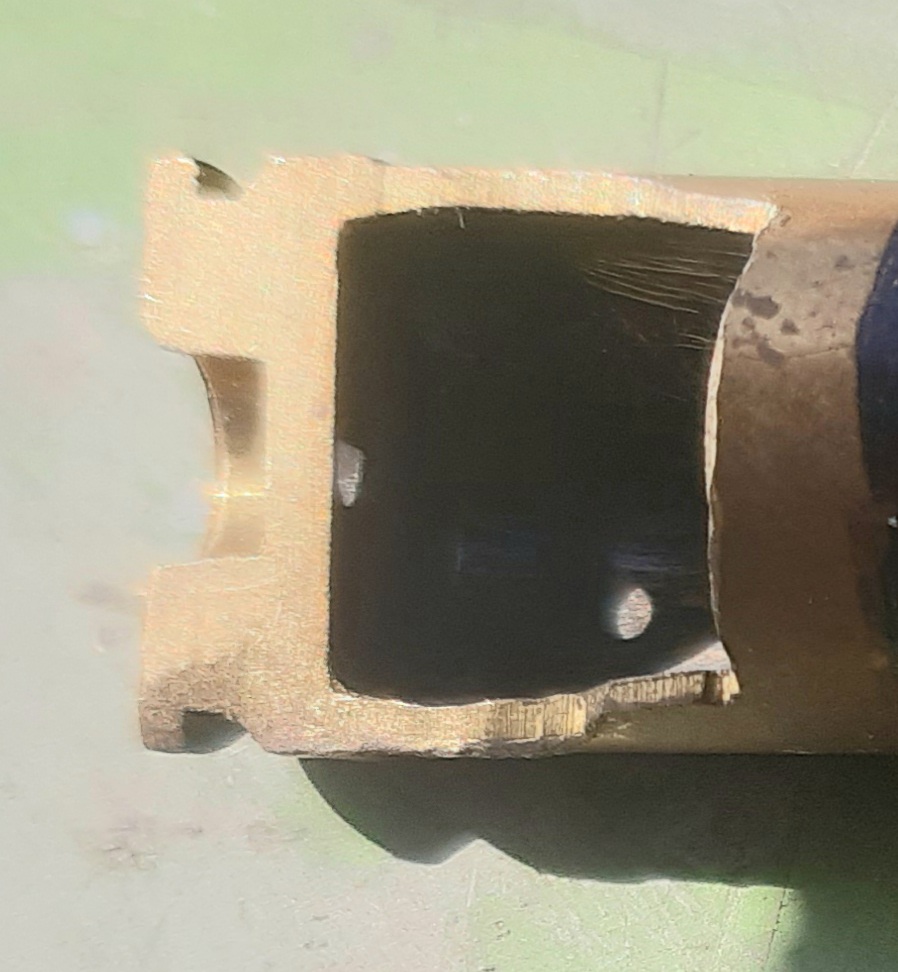

Soooo, after much pondering and searching I came across a bod who suggested creating a forward swell at top of shoulder neck junction in order to create minimal headspace where previously there had been many thou of gap. I pondered ways to do this, looking at oversize neck mandrels etc. All these options reeked of money and as I was also concernwd about overworking new brass I did more thinking and measuring. In conjunction with measuring fired and unfired internal and external neck and shoulder dimensions I then went to the saami chamber specs and cartridge specs to verify my measurements. The saami specs allow pretty generous room for neck expansion. Typically a 308 neck is specified to expand to .345" o.d. This is to allow for even the thickest neck wall thickness to still fully release the bullet on firing. The i.d. expands from .3075 to around .330", which is quite a bit. Relating to the common options some use for partial neck sizing to assist with minimal headspacing I figured that a suitable sized expander ball of about the size of the internal fired diameter of a 308 neck might be used to expand the neck of virgin 308 brass. Long story short I figured an 8mm (.32") ball would do it. I use hornady dies and found out the 8mm expander ball could radily fit as a substitute for my standard 308 ball. Duly acquired one and set the ball well low in the die and having applied plenty of Lee lube inside the virgin brass neck easily expanded it to i.d. 8mm. Then I measured the o.d. and it was .345", just shy of the sammi neck chamber spec. Next I took off the 8mm ball and refitted the 3075" ball, leaving it set well down in the die. I also loosened the die lock ring in order to play around with the resizing stroke to only resize the upper portion of the neck back to 308 spec. Doing it little by little and checking each time by chambering in the rifle I got to a nice snug bolt closure on my modified neck shoulder junction. Pic attached.

In theory this snug fit should stop or mitigate any case head expansin at first firing and assist in better fireforming of the shoulder area for future reloading. (Note; this idea is not designed to apply to already fired brass).

I don't think the little bit of working of the virgin neck is likely to need annealing until after first firing, but it is optional. I will only know if this works after several firings and reload cycles.

Note also that because of the altered shoulder-neck junction position the seating die setting will need adjusting for this initial firing, especially with internal seating guides like the hornady. In essence an extension of the shouldet had bern created to better fit the chamber for first firing.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 25

-

31-08-2024, 09:26 PM #1Member

- Join Date

- Jun 2014

- Location

- CNI

- Posts

- 5,987

Incipient head seperation and a possible mitigation method.

Last edited by Woody; 31-08-2024 at 09:43 PM.

Summer grass

Of stalwart warriors splendid dreams

the aftermath.

Matsuo Basho.

-

-

31-08-2024, 10:36 PM #2Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 6,048

Interesting. I have never been a fan of belted magnums for the reason you mention, although they do have a role in some African style straight walled cases. For bolt action rifles it just creates another headache, but your idea hear may be a suitable workaround solution. I have heard of one fellow who made his 7mmRM brass from .300WM for this reason, but again it struck me as a complete pain in the arse.

If this works, a forming tool that encloses the case and rotates a ball type thing in the right place might also work.

-

01-09-2024, 02:17 AM #3Member

- Join Date

- May 2012

- Location

- Sydney

- Posts

- 1,817

Incipient head seperation and a possible mitigation method.

I just adjust my fls die so the case fits in the chamber with a soft touch required on the bolt.

My cases last as long as my unbelted 06, .270, .308 brass.

Ignore the belt and size to the chamber or have I missed something?

Sent from my iPhone using Tapatalk

-

01-09-2024, 06:09 AM #4

Did anyone else hear Freddy Mercury and think of Highlander movie reading title?

75/15/10 black powder matters

-

01-09-2024, 08:30 AM #5

-

01-09-2024, 08:38 AM #6Member

- Join Date

- Jun 2014

- Location

- CNI

- Posts

- 5,987

-

01-09-2024, 10:07 AM #7Member

- Join Date

- May 2012

- Location

- Sydney

- Posts

- 1,817

Woody, serious question “why would this be different from new slightly under size brass in a belt less case design?

It flows forward regardless of the belt.

Sent from my iPhone using Tapatalk

-

01-09-2024, 10:23 AM #8Member

- Join Date

- Jun 2014

- Location

- CNI

- Posts

- 5,987

Its not. Its just that in my experience it seems more common in the old belted magnums. Sure, on firing the brass ows, but when its more than 3-4 thou the problen exacerbates. I wanted to reduce this length expadion from 10 thou" down to 2thou" in my rifle with virgin brass in an attempt to increase the number of reloads per case. I've measured the base to shoulder dimensions in my non belted cartridges and it seems chambering in modern rifles is less haphazard, being about 5thou over virgin case length. However, there is variation in case brands and individual rifle chambers so each requires individual assessment. The premature occurance of case head seperation I think is less common in cases without belts and with substantial shoulder profiles. I've made my own mid shoulder comparitors on lathe so its easy to measure case base to mid shoulder lengths with those and a caliper when setting resizing dies.

Last edited by Woody; 01-09-2024 at 10:31 AM.

Summer grass

Of stalwart warriors splendid dreams

the aftermath.

Matsuo Basho.

-

01-09-2024, 10:24 AM #9Member

- Join Date

- Mar 2012

- Location

- South Waikato

- Posts

- 8,555

-

01-09-2024, 11:44 AM #10Member

- Join Date

- Oct 2022

- Location

- Pukekohe

- Posts

- 1,172

I have no argument with the physics explained here and basically agree with you on what happens to new brass on initial firing. But, dont see how this might set up incipient head separation. At least, not based on my experience.

Belted mags I shoot are 300 Win Mag and 375 H&H. For both, after initially shooting new brass, I set FL dies to give headspacing on case shoulders, exactly the same as my non belted calibres. I don't have issues with head separation and case life typically runs between 10 and 20 reloads, the same as my non belted cases. I don't anneal anything even though I realise it might further extend brass life. My brass loss, typically, comes from primer pocket over expansion or cracked necks.

-

01-09-2024, 11:55 AM #11Member

- Join Date

- Jun 2014

- Location

- CNI

- Posts

- 5,987

Fair enough. You are fortunate that you chambers closely match your virgin brass. This is not always the case and this idea is to mitigate any mismatch of virgin brass to shoulder. If I can get to 10 reloads per case I will be pretty happy.

Summer grass

Of stalwart warriors splendid dreams

the aftermath.

Matsuo Basho.

-

01-09-2024, 12:42 PM #12Member

- Join Date

- Jun 2014

- Location

- CNI

- Posts

- 5,987

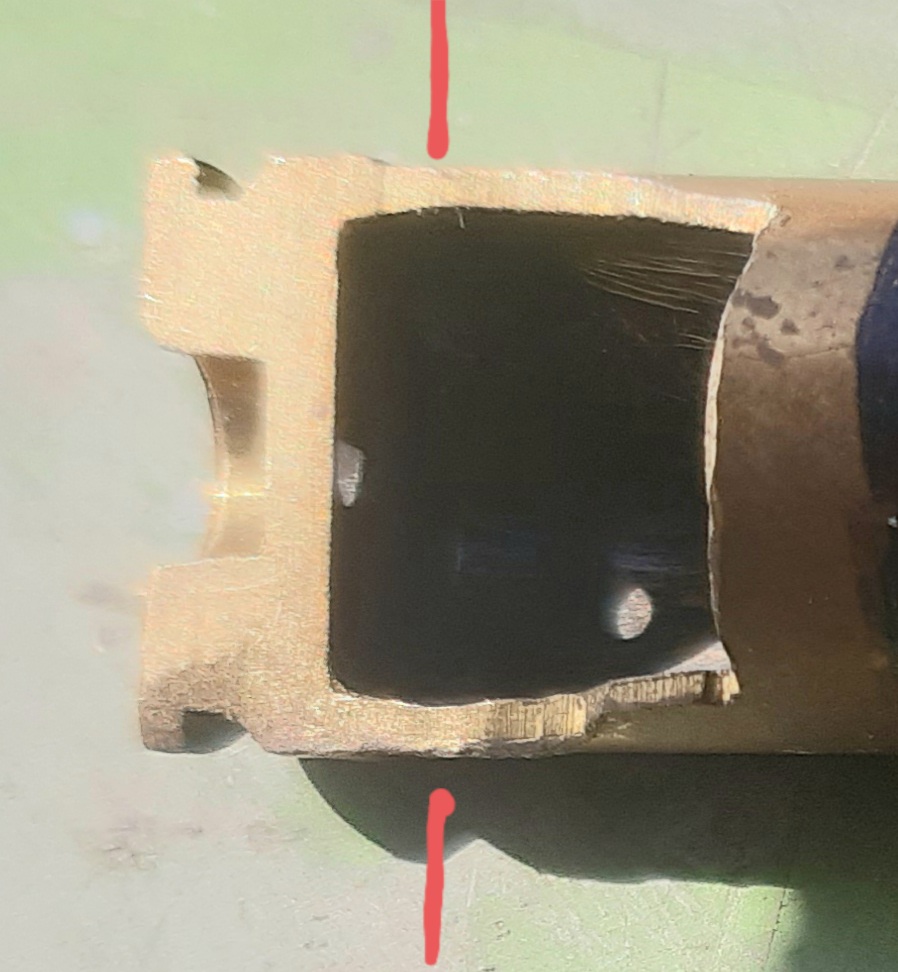

Incipient head seperation after 5th firing.

Summer grass

Summer grass

Of stalwart warriors splendid dreams

the aftermath.

Matsuo Basho.

-

01-09-2024, 12:50 PM #13Member

- Join Date

- Jun 2014

- Location

- CNI

- Posts

- 5,987

Better pic with case thinning just above the belt. Case fire 5 times. It might be good for 2 more but why chance it.

Summer grass

Summer grass

Of stalwart warriors splendid dreams

the aftermath.

Matsuo Basho.

-

01-09-2024, 01:08 PM #14Member

- Join Date

- Jun 2013

- Location

- Middle Earth

- Posts

- 4,545

Hi Woody,

What you have described is exactly what was written by ,( I think) Layne Simpson in an article in rifle magazine or handloader a few years back.

Some of the latest lapua (?)brass is available “long” so the you can adjust the headspace before your first firing , or at least to mitigate that thinking problem forward of the belt.

Larry Willis die in the USA is a sleeve collet system that allows one to resize the body of the case without touching the shoulder.

-

01-09-2024, 01:29 PM #15Member

- Join Date

- Jun 2014

- Location

- CNI

- Posts

- 5,987

Yes, i've of that Larry Willis die and gave it some thought. My rifle is 308 Norma mag from 1960s era and the only brass is from Norma. Howevet, I figured I may ad well try a low cost solution as an experiment. The rifle shoots sub moa so well worth looking at extending case life. Thanks for yr input though.

Summer grass

Of stalwart warriors splendid dreams

the aftermath.

Matsuo Basho.

Similar Threads

-

Case head seperation, .22 semi-auto

By ROKTOY in forum Firearms, Optics and AccessoriesReplies: 13Last Post: 04-08-2019, 09:54 PM -

Fave new method

By Pengy in forum Game Cooking and RecipesReplies: 2Last Post: 30-10-2016, 02:12 PM -

Game Animal Council survey of Battle for our Birds mitigation

By Meathunta in forum HuntingReplies: 6Last Post: 31-05-2016, 07:42 AM -

Carrying Water . . . . . what's your prefered method?

By The Rifleman in forum Gear and EquipmentReplies: 25Last Post: 10-07-2013, 10:31 AM -

case head seperation...help?

By tui_man2 in forum Firearms, Optics and AccessoriesReplies: 5Last Post: 14-03-2012, 07:39 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

15Likes

15Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks