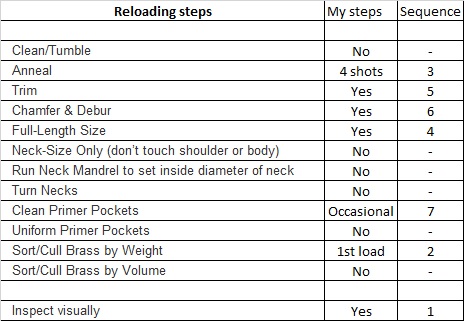

Reloading process and steps performed (survey):

https://precisionrifleblog.com/2024/...cription_popup

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 16

-

11-11-2024, 10:26 AM #1Member

- Join Date

- Mar 2012

- Location

- Christchurch

- Posts

- 1,493

Reloading Process and Steps Performed

-

-

11-11-2024, 04:16 PM #2Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 3,179

Greetings @rupert,

An interesting. I have often thought that some handloaders become slaves to the process and add steps that they like the sound of rather than increasing precision. I guess we are all prone to this to some extent. It was interesting to note that some of the top shooters had quite simple routines that gave excellent results. Perhaps when you need to load thousands of rounds pa you would tend that way. Perhaps there is something for all of us to learn.

Regards Grandpamac.

-

11-11-2024, 04:37 PM #3

-

11-11-2024, 06:16 PM #4Member

- Join Date

- Aug 2024

- Location

- Waikouaiti

- Posts

- 343

No wonder I cant hit anything. I have only 3 steps.

-

11-11-2024, 08:32 PM #5Member

- Join Date

- Mar 2012

- Location

- Hastings

- Posts

- 2,890

-

11-11-2024, 09:33 PM #6Member

- Join Date

- Mar 2012

- Location

- Christchurch

- Posts

- 1,493

Makes me think a bit more about which steps I can put aside (primer pocket cleaning) or do more of, e.g., neck annealing.

-

12-11-2024, 04:07 AM #7Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,618

I don't do much target shooting and when I do its not chasing a golden bullet..I do hunt and my accuracy criteria is all about putting an animal on the ground under 300m and mostly under 100m. I don't buy new, single lot, Alpha, Lapua or any other brand new brass. Nearly all my brass across my various calibres is at least fired once except for the occasional pkt of new Starline brass I've bought because that was all I could get. I don't often miss a kill these days but I do have mediocre range scores. 99% of those would give me a kill in the field. I have a lot of fun and enjoy reloading. I uniform flash holes once, always FL size except 303B, always clean, trim brass about every 3rd time, chamfer and polish case mouth when trimming. I never neck turn, I anneal every 2nd firing, and always clean the primer pocket. I leave the expander button on the depriming rod but thinking of doing without it. I sort my brass by HeadStamp but load different HS at the same time to the same spec. Never noticed any material diff shooting them. But then maybe I'm.just not that good of a shooter for that level of OCD to make a diff. I ate venison twice this week and goat once.

I know a lot but it seems less every day...

-

12-11-2024, 08:18 AM #8Nakihunter

- Join Date

- Jul 2018

- Location

- New Plymouth

- Posts

- 127

This is what I do. I do not trim unless necessary.

I partial FL size using the Hornady headspace comparator. I do not set back the shoulder 2 though but just get it back to fired case dimensions.

Now a days most of my loads are below max and most of them do not need case trimming at all even after 5 or 6 shots.

-

12-11-2024, 10:34 AM #9Member

- Join Date

- Aug 2019

- Location

- North Canterbury

- Posts

- 313

66% of these top-ranked shooters reported that the muzzle velocity of their ammo had a standard deviation (SD) of 5 fps or less,

Thatís way more than dozen steps of case preparation

-

12-11-2024, 10:54 AM #10

-

12-11-2024, 03:07 PM #11

Decap

Wet tumble

Resize

We tumble again (lanolin lube is sticky shit)

Case prep done.

Prime

Powder

Bullet

Done.

-

12-11-2024, 04:33 PM #12Member

- Join Date

- May 2012

- Location

- Sydney

- Posts

- 1,808

Remove the tumbling steps, insert clean primer pockets, add a case trim and annealing every three or 4 loadings and you have my process. New brass gets a case mouth chamfering.

-

13-11-2024, 01:24 PM #13Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 3,179

Greetings all,

Reloading process can be quite personal. Much of what we do is by choice rather than need so here is my routine, make of it what you will.

1. Cases are deprimed in a punch and base set from a Lee Loader. Primer pockets are cleaned with a small screwdriver and the outside of the cases cleaned with a Scotch Brite pad or steel wool if really dirty.

2. Cases are inspected for any cracks and signs of a head separation.

3. Cases are annealed every second load with the candle method.

4. Cases for light loads are neck sized. Those for the .303 are sized in a Lee Loader and the others with appropriate neck dies. Full power loads have cases Full Length sized using the Redding competition shell holders to set the head space. I have been thinking of sizing without the expander button fitted and then running the expander button in and out as a separate step as this supposedly can deliver straighter necks. The jury is still out on this one.

5. Cases are trimmed in a hand trimmer to 0.1mm short of max.

6. Cases are primed in a hand primer.

7. Powder is weighed on an electronic scale and checked on my old beam scale. A bit of OCD going on here, more later.

8. The powder charge goes in the case and the case transferred to the press looking down to see that the case is charged and the projectile seated. I have always done it this way and see no reason to change.

9. Finally the completed cartridge is weighed to ensure that there is powder in every one.

10. Loading records are completed for each batch of handloads and the rounds boxed with data under the box lid.

I don't sort new cases by weight or volume but do have batches of cases of the same weight but different head stamp to more easily keep track of the load count.

Regards Grandpamac.

-

13-11-2024, 02:30 PM #14

Load 50 rounds sight in sell gun

Sent from my iPhone using Tapatalk

-

13-11-2024, 10:25 PM #15

Similar Threads

-

Motorcycle workshop steps up

By nor-west in forum Firearms, Optics and AccessoriesReplies: 1Last Post: 27-09-2022, 08:05 PM -

Small steps

By madjon_ in forum Projects and Home BuildsReplies: 1Last Post: 28-07-2020, 08:39 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

18Likes

18Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks