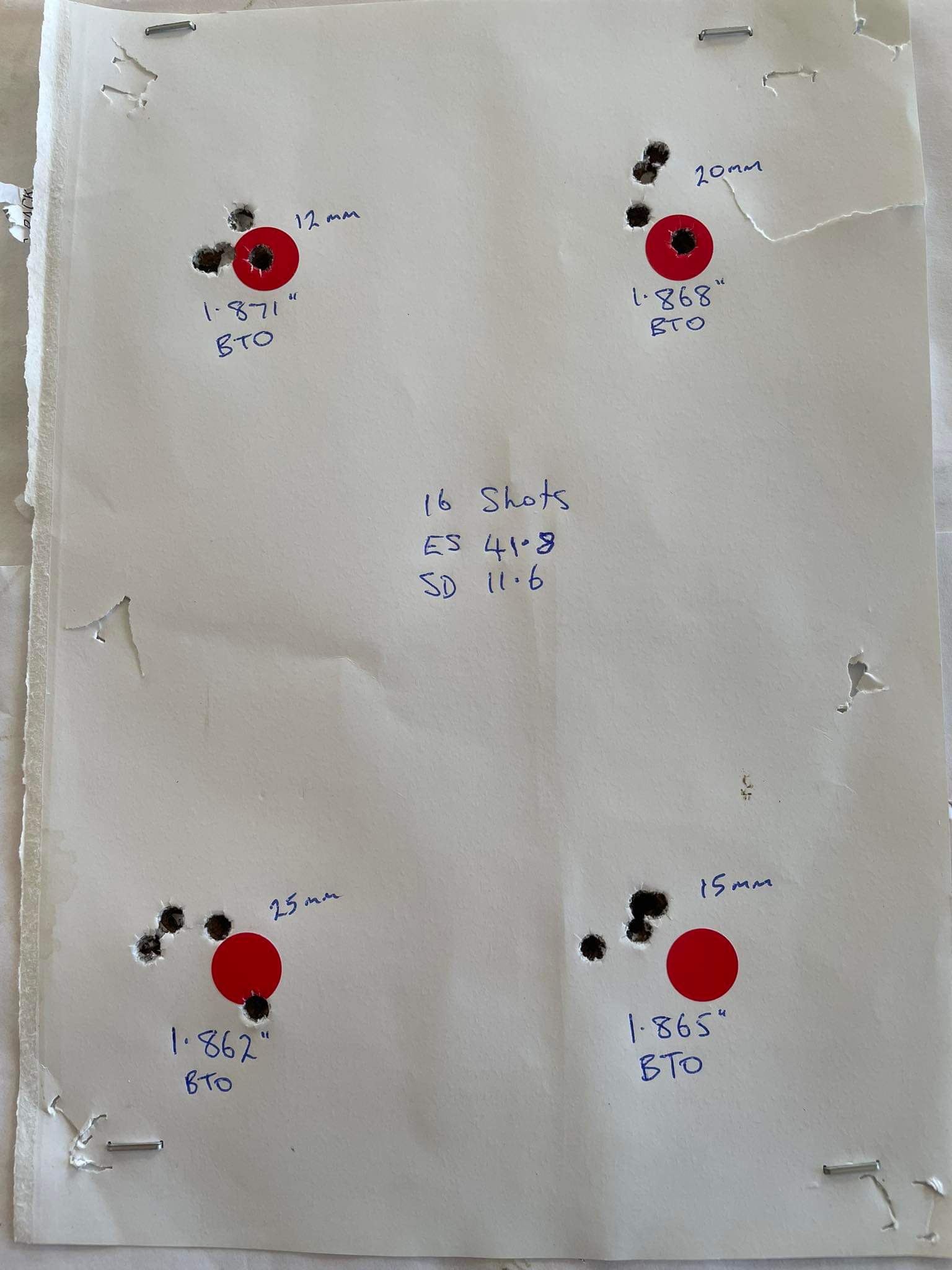

I enjoy reloading and my process is normally find a decent velocity with good SD and ES and 20 thou jump, then tune seating depth in 3 thou shorter increments.

Did this today at range with 223 I’ve just got shooting 65gr SGK and BM2. 0.2 grain over max.

But…..then I read all of @gimp posts regarding accuracy. Based on that, does this tell me nothing? And if I was really interested in finding out about accuracy, I should’ve just shot some 10 shot groups with the right velocity load that I liked?

Stings a bit to think of all wasted time and components if all this is true.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 45

-

12-07-2024, 07:57 PM #1Member

- Join Date

- Nov 2012

- Location

- NI

- Posts

- 1,755

Seating Depth Test. Waste of Time?

-

-

12-07-2024, 08:09 PM #2Caretaker

- Join Date

- Dec 2011

- Location

- Hawkes Bay

- Posts

- 9,608

Not everything you read on the internet is useful

Had you not read that you would be off happily hunting and sending animals to the chillerA big fast bullet beats a little fast bullet every time

-

12-07-2024, 08:12 PM #3Member

- Join Date

- Nov 2012

- Location

- NI

- Posts

- 1,755

-

12-07-2024, 09:00 PM #4Member

- Join Date

- Jul 2012

- Location

- Tauranga

- Posts

- 2,637

Don't worry have a read of the same question on the accurate shooter forum

https://forum.accurateshooter.com/th...#post-38990711

-

12-07-2024, 09:20 PM #5Member

- Join Date

- Jul 2012

- Location

- Invervegas

- Posts

- 5,700

Not too many people in that thread seem to understand the power of statistical testing methods. Once one does, seating depth doesnt matter.

-

12-07-2024, 09:21 PM #6

Ironically I'm out happily hunting but I'll put together a post when I'm home next week

-

12-07-2024, 09:22 PM #7Caretaker

- Join Date

- Dec 2011

- Location

- Hawkes Bay

- Posts

- 9,608

That thread completely misses the point from the second post onwards

Accuracy has everything to do with a consistent barrel harmonic

Everything you do with ammo alterations/ bedding/ tuners etc is to alter barrel harmonics so that the barrel crown releases the projectile in the same harmonic “place” as the previous shots

A muzzle moves considerably in relation to the point of aim with each shot

The more consistent you can get the harmonic “ wave “ as it travels the barrel the more “ accurate” the rifle

All barrels flex with harmonic waves -watch a 50 fired in slow motion

To repeat - all ammo adjustments alter barrel harmonics, there’s a huge complicated synergy between internal ballistics and barrel vibration/harmonics

Some ask the question……why/how does ammo adjustment alter accuracy, it’s because it alters a barrel harmonic

This article barely scratches the surface

https://www.guntweaks.com/barrel-harmonics.htmlu

A pedant could feed on it for years, a hunter just goes and lives lifeLast edited by 7mmsaum; 12-07-2024 at 09:32 PM.

A big fast bullet beats a little fast bullet every time

-

12-07-2024, 09:52 PM #8Member

- Join Date

- Jul 2012

- Location

- Tauranga

- Posts

- 2,637

@7mmsaum you may need to have a look at that link... it comes up 404

BTW I don't do seating tests. I prefer to jump bullets and test for the velocity I want. Once I have the true velocity I will get my charge weight tweaked with the OBT feature on GRT.

It works for me.

-

12-07-2024, 09:56 PM #9Caretaker

- Join Date

- Dec 2011

- Location

- Hawkes Bay

- Posts

- 9,608

There’s a zillion articles on barrel harmonics

https://huntinginaustralia.au/rifles...rel-harmonics/Last edited by 7mmsaum; 12-07-2024 at 10:02 PM.

A big fast bullet beats a little fast bullet every time

-

12-07-2024, 10:05 PM #10Member

- Join Date

- Mar 2012

- Location

- Hastings

- Posts

- 2,952

-

12-07-2024, 10:06 PM #11Caretaker

- Join Date

- Dec 2011

- Location

- Hawkes Bay

- Posts

- 9,608

-

12-07-2024, 10:10 PM #12

I must admit that Gimp has really upset my peaceful world of reloading.

After the initial “ this is Bullshit “ reaction.

I realised that although my observations aren’t exactly the same, there have been instances of similarities that are freakishly in the same ballpark.

I’m in the throes of doing an extreme makeover of my load development process .

If this proves itself to be both productive and efficient all I can say is .

Bugger………FALL IN LOVE WITH THE NUMBERS , NOT THE IDEA

-

12-07-2024, 11:18 PM #13Member

- Join Date

- Jan 2020

- Location

- porirua

- Posts

- 855

If you shot at hv da today that range has some really weird crosswinds and with 20 knt southerly I flagged it , the old porirua range was way more consistent even in a 3o nkt norwester as it was behind and just raised the group an inch or two .

-

15-07-2024, 07:52 PM #14

I think there are a couple of different ways you might look at this. Here's my thinking right now.

The process generally followed for load development (which it appears you are following, and which I also followed for many many years) is basically an attempt at optimisation, rather than working to meet a specific objective. Running a series of tests where you control different variables, with the hypothesis that changing these variables changes the load characteristics, and that you can use the test data to select the best combination of variables to get the best load, defined as the load expected to produce the best precision possible (or lowest velocity SD, or both), without regard to requirements.

The tests we use however are flawed for selecting the load with the best precision (or lowest velocity SD), when the differences are small or moderate. From comparing single 3 or 5 shot groups, we do not get sufficient information to state which combination gives the best, or the worst, result - or to confidently identify whether there is a difference. From the selection of 4-shot groups above in your seating depth test, I am unable to identify whether there is any difference between them or not.

It is probably prohibitively time-consuming and expensive to really identify which is the best combination - it may not be a practical approach to look for optimisation in this way. The differences may be non-existent, or insignificant in a practical sense even if they can be identified through a more robust testing process.

An alternative is to take an objectives-based approach to developing a load. What are your requirements? Define these, then if a load meets your requirements, you are done. This however requires some re-framing around the definitions of your requirements compared to common usage.

What are the criteria for requirements? They will vary depending on your specific use, but I would think to start (once you have selected the appropriate components most likely to give the result you want):

- Sufficient precision from the system that, excluding shooter proficiency in the field and weather/ballistic effects, hit probability is high for the targets/ranges I require the rifle to perform at. For a big game hunting rifle, used at conventional distances, this might be that you need the rifle to consistently (say 95% of shots) be capable of hitting a 50mm circle at 100m - a "2moa" rifle. This is a realistic expectation for a hunting rifle when you get a genuine measure of precision.

- Velocity within your required range. this is likely defined by what you need the projectile to do. Setting requirements for this does involve being sensible at the time you select your cartridge. You will not get sufficient speed from a .223 with an 18 inch barrel to have a 80gr ELDM expand at 700 metres. You will get sufficient speed for it to expand at 400 metres. For this you require 2550fps at the muzzle. If your requirement is to shoot deer at 400 metres with your .223 and the 80gr ELDM, your velocity requirement is 2550+ FPS at the muzzle. Increases in velocity result in only vanishingly small improvements in hit probability; so the main sensible reason I can currently identify to be seeking velocity is for projectile performance on target.

- Consistent velocity - yeah your ES and SD. It's worth being aware of how much this really matters to set your requirements - for conventional hunting - you can more or less ignore it. For very long ranges it becomes significant. It is not clear that there is anything that can be done with load tweaking to improve it, if you are using good components and have a good reloading process with quality equipment set up correctly, it is what it is.

Hit probability is a subject in itself worth examining, one of Bryan Litz's books is gathering dust on my reloading bench and contains quite a comprehensive examination of the subject. I will have a look at which one so the discerning reader can find out more.

This testing can be done at a much coarser scale than making small tweaks to powder charge/seating depth. If, with a valid measurement, a combination in a .223 does not shoot precisely enough for your requirements at 24.5 grains of 2206H it will not at 25.0 grains. Try a different combination (powder, bullet, etc). It may shoot better at 22.0 grains than at 24.5, but if that is outside your desired velocity window it is irrelevant to test it.

I have not specifically tested small changes in seating depth to test whether there is a change in precision. Within your functional window for your requirements there are limits - generally for practical use we need to seat shorter than mag length, and some distance off the lands, while keeping our ogive outside the case. Generally in practical terms seating something around .020" off the lands as a starting point seems to give precision that meets requirements as long as it fits in your magazine. It may be that there is a difference in precision between seating .020" off, vs .500" off - with the expectation that the shorter jump would be more precise - however it's not clear why you'd ever load .500" off if there was a choice. To quote Miles Neville from Hornady - set your OAL .030" off the lands and forget your seating die is adjustable. This to me has been a practical solution.

This gentleman presents some interesting information on the validity of selecting loads based on small tweaks to seating depth and the difficulty of meaningfully identifying differences - https://www.youtube.com/watch?v=_h4iAiGYbwg

All the theory in the world about harmonics is wonderful, but my interest is - what is the most efficient way to get a realistic and practical understanding of whether a load meets requirements?

-

15-07-2024, 07:57 PM #15

Incidentally an SD of 11.6 over a reasonable sample size is getting up there as one of the best I've actually seen from a .223 load yet

Similar Threads

-

When to re optimize seating depth ?

By Bagheera in forum Reloading and BallisticsReplies: 7Last Post: 02-11-2018, 10:34 PM -

6.5x55 seating depth

By Sr5dan in forum Reloading and BallisticsReplies: 18Last Post: 09-10-2018, 11:04 PM -

Seating depth

By Jackangus in forum Reloading and BallisticsReplies: 7Last Post: 16-03-2015, 10:00 AM -

help with seating depth

By Dino in forum Reloading and BallisticsReplies: 10Last Post: 08-09-2013, 09:12 PM -

seating depth changes

By Neckshot in forum Reloading and BallisticsReplies: 3Last Post: 22-04-2013, 11:31 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

53Likes

53Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

then keep shooting and share the venison with yer mates

then keep shooting and share the venison with yer mates

Bookmarks