Here I am derailing another thread getting on this topic, but it is really sensible to think in terms of "requirements" and meaningfully test whether the system meets those then move on, rather than thinking about precision optimisation without an acceptance threshold

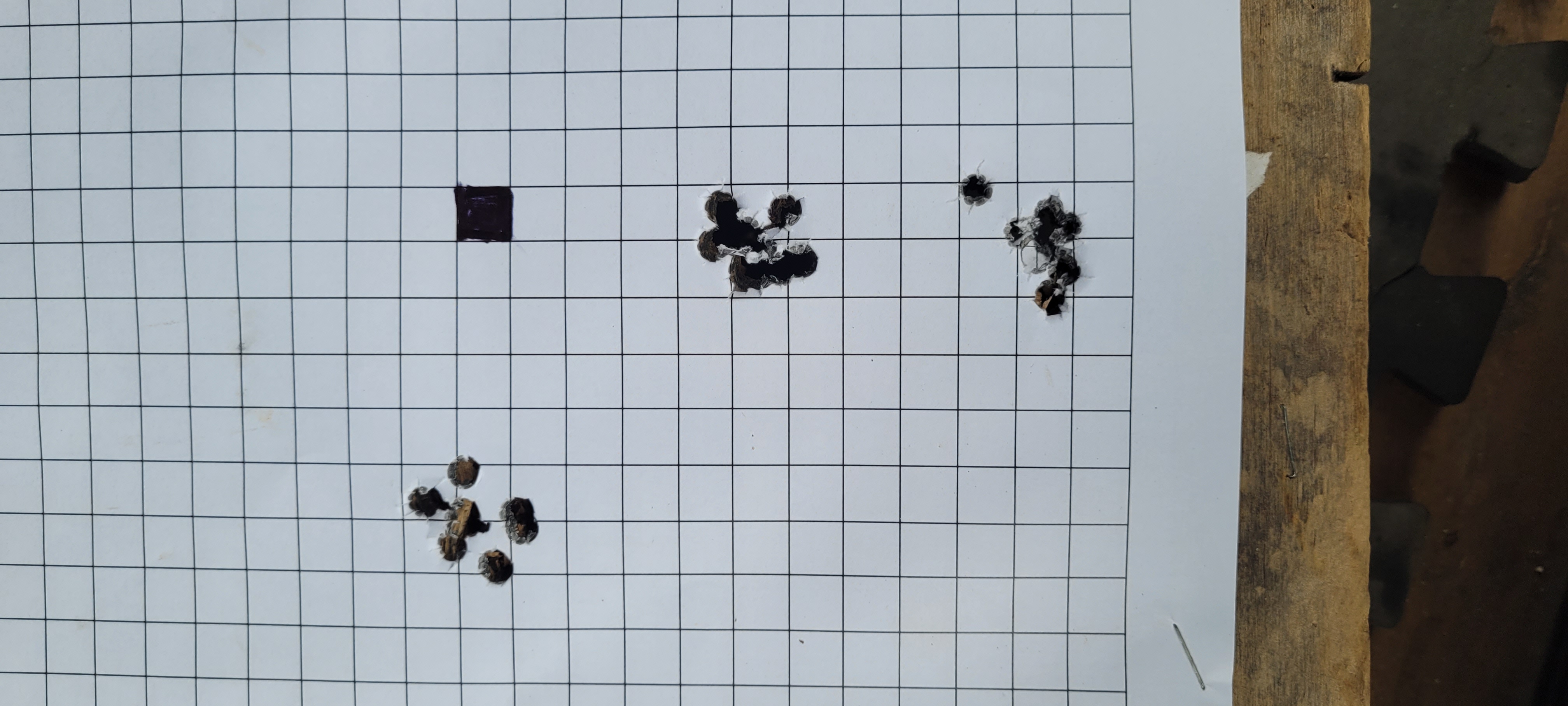

For example these 3 10rd groups (of 3 different powders loaded with the same bullet) are all different sizes, however the precision of all 3 is functionally more or less the same - 0.05-0.06 MRAD mean radius.

I don't actually care if one is "better" than the others. The test is - do they meet requirements? They all do, for precision - the predictive O95 is 0.2 - 0.24 MRAD, but the error bars mean we can't say there's actually any difference. Either of these values meets my requirements threshold - neither of these values produces a meaningful difference in hit probability at long range. I can select the load that meets my other requirements. If they all do, great. Only 1 of these 3 powder loads met all of my requirements. It is the first group below the aiming point dot. Load development completed - off to kill things and compete.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 1 to 15 of 27

Thread: Shorter Barrel 223 data

Threaded View

-

04-10-2024, 12:42 PM #26

Similar Threads

-

Myth? - shorter barrel = use faster powder?

By Hermitage in forum Reloading and BallisticsReplies: 52Last Post: 01-08-2021, 05:45 PM -

6.5 prc 28inch barrel load data

By 300wsmPete in forum Reloading and BallisticsReplies: 4Last Post: 25-08-2020, 10:24 PM -

6.5x47 Short Barrel Data enquiry

By quadhunter260 in forum Reloading and BallisticsReplies: 2Last Post: 25-05-2020, 06:26 PM -

Shorter barrel = less velocity?

By XBoltstalker in forum ShootingReplies: 30Last Post: 22-09-2016, 06:54 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

9Likes

9Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks