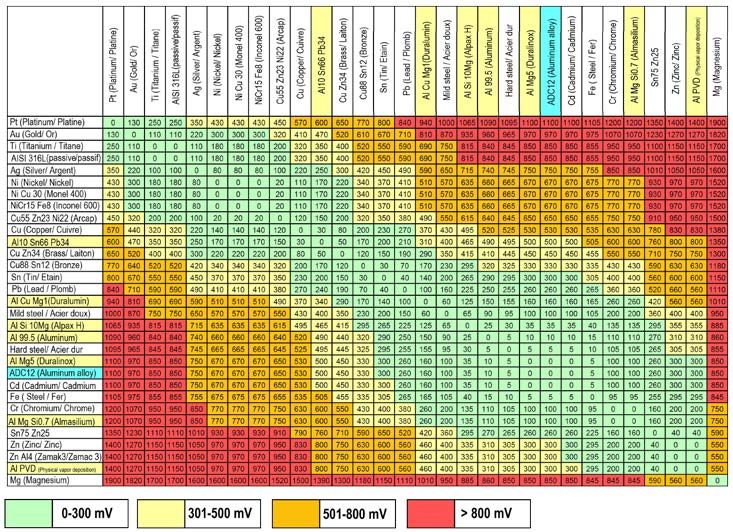

I was thinking about the same thing... my issue is whether nickel will lead to galvanic corrosion.

https://www.jpcfrance.eu/technical-i...on-resistance/

A pure guess would be on molybdenum or Teflon grease to help reduce binding or galling... would probably pay to try it on an aluminium test thread first, but by all accounts they seem to fit the bill in that they are relatively inert with aluminium and not heat sensitive.

I suspect what's happening to people is a mix of things - some mild corrosion due to fouling and moisture, some mechanical binding due to fouling, some mechanical binding due to minute amounts of galling, and some mechanical binding due to heating and cooling allowing the threads to further lock together. Judicious application of heat and cold can often free up a stuck thread... so I'm told

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 1 to 15 of 52

Thread: DPT Suppressor seized up

Threaded View

-

12-03-2021, 10:35 PM #11

Similar Threads

-

Best Overbarrel. 22 suppressor - anyone used a centrefire suppressor on a rimfire?

By 308mate in forum Firearms, Optics and AccessoriesReplies: 23Last Post: 10-12-2020, 02:06 PM -

Suppressor cover for ODL 7.62 QD suppressor

By eamars in forum Firearms, Optics and AccessoriesReplies: 23Last Post: 28-05-2020, 06:36 PM -

seized suppressor

By crewe2 in forum Firearms, Optics and AccessoriesReplies: 48Last Post: 03-11-2018, 09:09 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

86Likes

86Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks