In a recent thread I was looking for a taller front blade for my 1915 SMLE III Bush rifle. I bought this ole gat in 2019 off the Yellow Site when overseas cruising my TM searches over morning coffee. It had a Buy Now of $150 on it and an interesting story. The owner, an old pig hunter and possum trapper, put it down one day when on his trap line and didn’t find it again until 2 ˝ yrs later. The barrel was toast. An armourer mate in the Army found and fitted a pretty decent replacement barrel and it was returned to bush duty. Hanging up his boots he put it up for sale. How could I resist? I shot it a few times and it did ok but the sights were way off as the barrel is now only 19in. So it sat until this year I got around to having it threaded, the apparently non-standard front sight moved back, and replaced the rear elevator sight with one that had windage adjustment. A DPT barrel-forward suppressor was added and off to the range I went.

At 100m standard military 174gn FMJs were hitting around 8” high with the rear sight at its lowest available adjustment. A taller front blade was needed. Nothing was found but the best suggestion I got was simply determining a rough height using a bit of electrical tape folded and pressed to the existing blade, then fabricating something or adding something to the existing blade. Three shots at 50m with 174gn M-rounds told me what I needed to know.

Back home a few days later I was moving stuff around, doing some sorting and tidying and came across an old, chromed brass window latch component. It looked exactly like an oversize front sight lol. It didn’t take much to figure out that with hacksaw, file, and my dial caliper, there was enough meat in the brass and to spare to fabricate a new front blade to slot into the dovetail. I drifted the existing blade out of the sight base and discovered the dovetail channel was barely that. Only a thou and a half difference from one side to the other, bottom to top. And while the blade tapped out easily, it was actually locked in with solder.

I got to work and with about 5 hours judicious sawing and filing hacked out a rough design. Early on I realised I could make this to hold a 2mm fibre optic insert. For my old eyes, a vast improvement on a thin painted bit of steel. So that’s what I did. It aint pretty.

With it roughed out and heated to reset the solder bed I headed to the range. A box full of an incremental load test with hard cast 190gn gas checked conical flatpoints went with me. I had made these up in 4 round steps of 0.2grn increments with SR4759 way back in Jan 2020 with the idea of finding an accurate subsonic and a 1400-1600fps hunting load for another 303B rifle. I had not yet suppressed it but was chronoing the loads and shooting for group. The results were quickly ugly from the Sporter with a 22in barrel. First the scope would not hold zero, a problem with the old rings. Second, starting at the middle load of some 16 steps and moving down through the steps, after 1 or 2 from each of three, none of them would stabilize. Bullets at 50m were tearing holes in the card sideways and were sprayed everywhere. I packed it in and put the box of loads away thinking I would one day pull them and try some other combinations of projectile and powder. Nevertheless, as happens, I never got to it so I thought why not, I’ll see what happens with the Shorty.

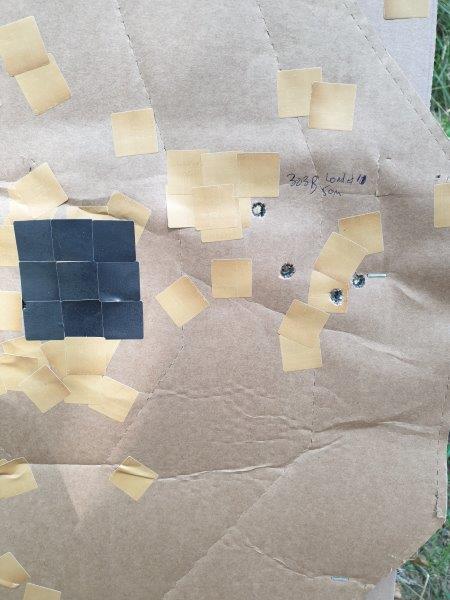

First up I took a guess at elevation and put three 174gn military rounds on paper at 50m. Quickly I found I had plenty of up and down movement in the rear elevator with a setting at 225yrds nominal giving me the correct elevation for the 174gn at 50m. Yay! So again I started at midpoint with the cast loads and went down through several to the lowest, suppressor off. Elevation was no problem to determine and a pleasant result with perfect round holes all the way down to the 2nd from lowest load. Then on the lowest, under subsonic velocity, one of the three bullets appeared to strike less than square. Unfortunately, the groups were less than encouraging with shots hitting within anything from an 8 to 10 inch radius and definitely not in a circle. So back to the next up from the middle load and moving upwards from there. I was shooting 4 rounds for each load other than the three I had previously tested, walking down to the target to check (no spotting scope), recording the result then patching. By the time I got back and reloaded the barrel was mildly warm. Every doz shots or so I ran a pullthu once through the barrel to check it was not over fouled or leaded – not that I expected leading but hey… I was running out of time by now, getting reliable neat round holes still but no group. The thump on my shoulder was getting more intense with each step and it’s a pain in the arse getting old!

I was about to pack it up with the most recent load all over the show thinking the whole thing was a bust. Also the velocity, not using the chrono this day, was starting to feel like it was getting up there for cast, guessing above 1600fps. But… just one more … and what do ya know, it was the load that produced the goods. Three in a nice group for this rifle, one slightly off. So back to the bench to neaten up the brass, let a little more light onto the fibre optic, and move it slightly better to centre for the windage as shots were consistently to the right across all loads requiring more windage adjustment than I wanted as a starting point. I tapped the sight out, removed the fibre optic, hit it with the file, resoldered it, sprayed it with some matt black paint and installed a new bit of fibre. The red dot is much more visible with the extra light and a finer sight picture with less brass around it. Can’t wait to get back to the range with some more of that particular load and the DPT can installed at the front. I’m not too fussed about sub loads but am very keen on cast at around the 1400-1600fps for a 50-80m bush rifle. Here are some pics, well, a lot of pics sorry…

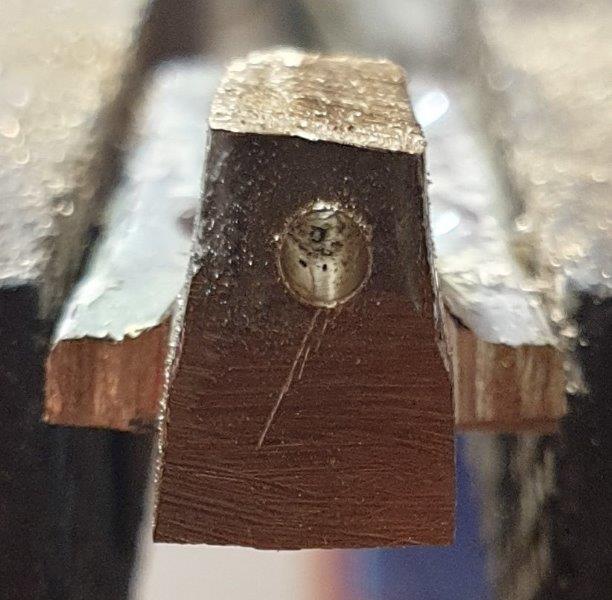

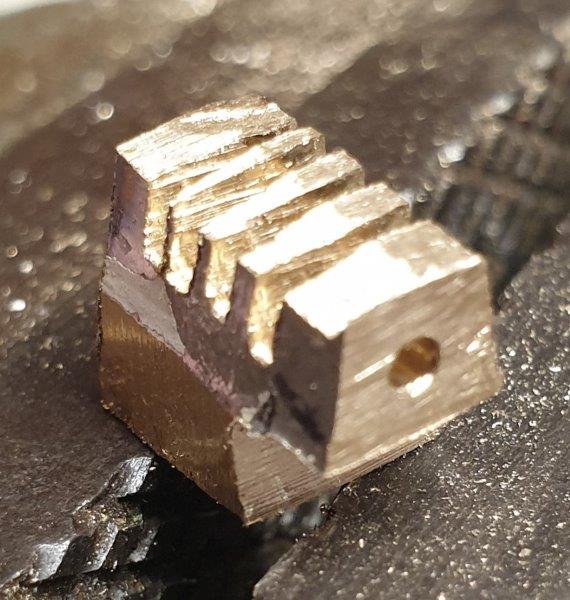

Starting out, the found brass and the original sight blade, chopping and filing

Rough enough...

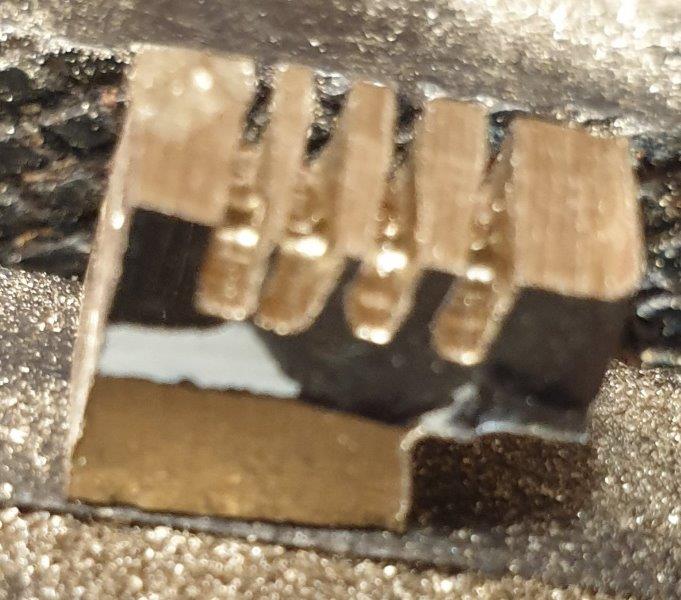

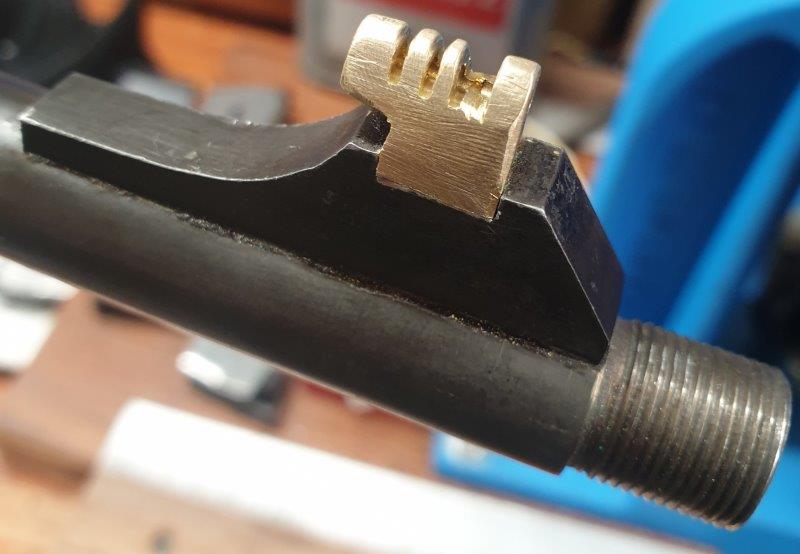

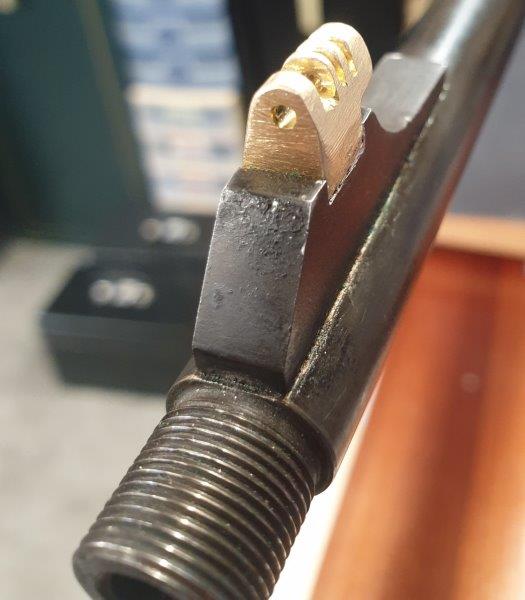

First fitting

Soldered, fibre installed and off to the range

The last, and only decent group, 50m, off a basic front rest

Back home, brass removed for finer profile and more light on the fibre

Paint job, rough enough...

And, da daa...

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 11 of 11

18Likes

18Likes

Thread: The sight that Bubba built…image intensive!

-

22-02-2024, 08:21 PM #1Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,620

The sight that Bubba built…image intensive!

I know a lot but it seems less every day...

-

-

22-02-2024, 08:29 PM #2

Bwaaahaha..... thanks for a jolly good laugh Jhon, but hey..... it sorta works

hot barrels bud

-

22-02-2024, 08:30 PM #3Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,620

It seems the Edit and Go Advanced functions are not working properly...No txt or content appears in edit window...so here is a final pic...

I know a lot but it seems less every day...

I know a lot but it seems less every day...

-

22-02-2024, 08:34 PM #4Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,620

-

22-02-2024, 09:52 PM #5Member

- Join Date

- Jun 2023

- Location

- waimakau

- Posts

- 4,395

Are you going to do a run of them

-

22-02-2024, 09:56 PM #6Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,620

-

22-02-2024, 10:22 PM #7Member

- Join Date

- Jul 2013

- Location

- Waikato

- Posts

- 2,576

Need to do something for my Rossi 44,getting hard to find front sight when bush hunting.

-

23-02-2024, 07:29 AM #8Member

- Join Date

- Jun 2015

- Location

- Bay of plenty

- Posts

- 801

Maybe we need a Kiwi “Bubba” page?

-

23-02-2024, 08:46 AM #9Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,620

-

23-02-2024, 08:55 AM #10Member

- Join Date

- Nov 2021

- Location

- Waikouaiti

- Posts

- 642

Brilliant!

-

23-02-2024, 08:58 AM #11Member

- Join Date

- Apr 2019

- Location

- Canterbury

- Posts

- 78

Thats some kiwi can do, love your work mate.

Similar Threads

-

Bubba what have you done?

By Rock river arms hunter in forum Firearms, Optics and AccessoriesReplies: 416Last Post: 26-02-2025, 01:47 PM -

WTF Bubba

By Beetroot in forum Firearms, Optics and AccessoriesReplies: 32Last Post: 11-11-2023, 06:03 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks