We've debated this before. Here's some of that rare commodity known as "evidence".

Vehicle: 2014 Gen 7 Hilux (KUN26R) with the 1KD-FTV motor, 150,000km

Use: Overlanding around Aus, then hunting and general rural lifestyle in NZ.

At least half the mileage has been towing a camper trailer or quad & bike, the remainder carrying a constant full load, with a great deal of hard off-road driving. Air lockers front & rear, lots of other off-roady mods.

There were four options to prevent the infamous diesel engine intake blockage:

I wasn't happy with blanking or restricting the EGR for various reasons, that I'm not going to debate. Don't bother trying to tell me to blank / delete the EGR, I'm not going to.

- EGR blanking plate (complete blank or 7mm hole)

- Fit a catch can

- Do both

- Do nothing

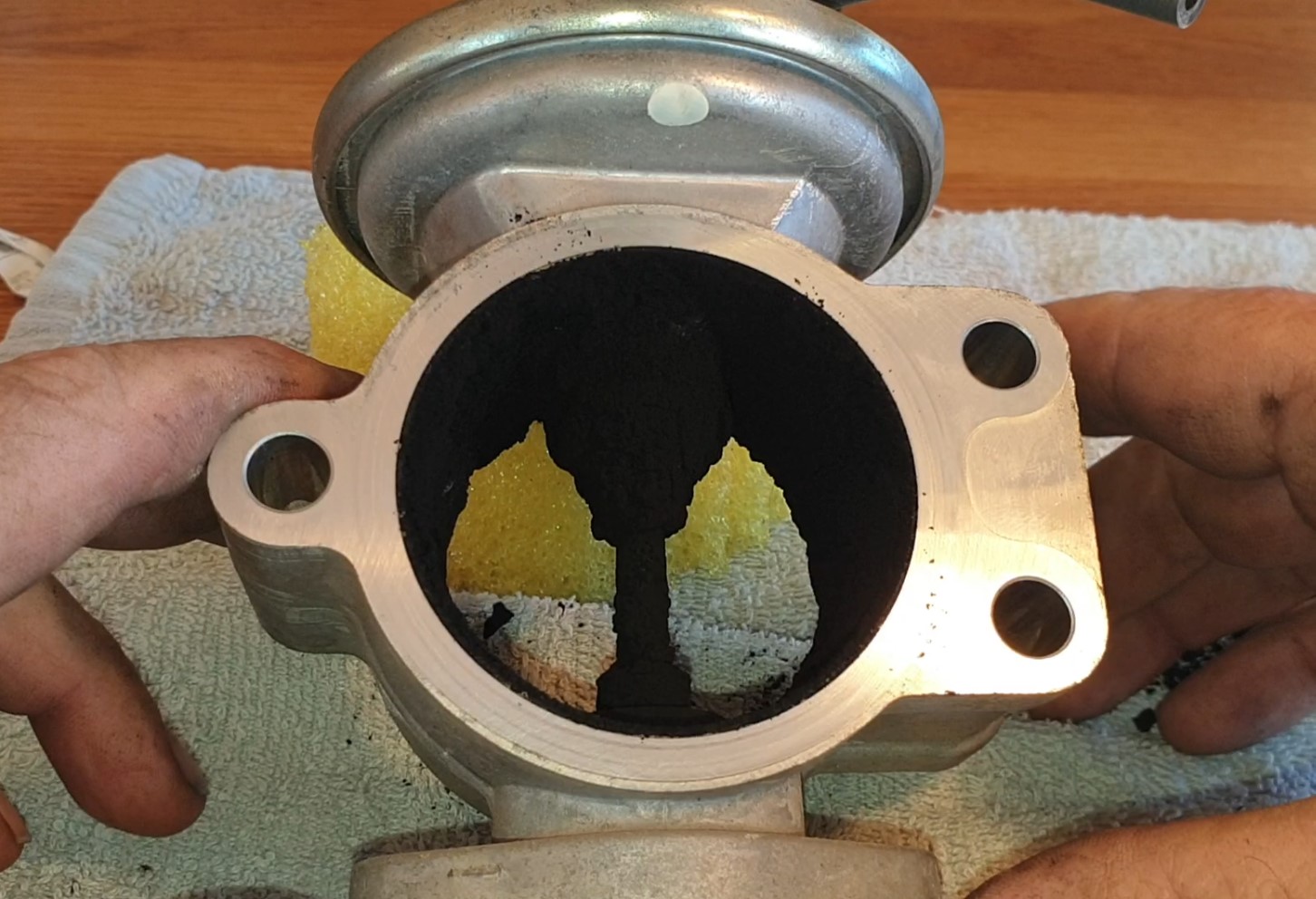

So I fitted a Provent 200 when the vehicle was brand new. What I expected from the Provent was for it to stop the build up of the rock solid tar around the EGR valve, in the elbow behind it and down into the intake manifold. This because the catch can would remove the oil vapour from the crankcase vent. Therefore, the hot recirculated exhaust gas carrying diesel particulate "soot" wouldn't mix with oil vapour and coagulate and harden over time, building up an ever increasing restriction in the intake. When that happens, the intake restriction can cause significant detrimental effects - power and fuel economy both suffer. The black, hardened tar is also a complete bastard to remove, requiring solvents and lots of scrubbing. A bad case in the intake manifold is a bitch to rectify.

The result was exactly what I expected, and wanted to see. Only a slight decrease in the valve internal diameter, loose, soft, easily removable soot. Very pleased with the outcome. I've not noticed a performance loss, fuel economy has remained constant since new. No codes or any other bother. I can see from the amount of soot that just fell off as I removed the valve, that a lot of this is removed by air flow into the combustion when you give it the berries. The "Italian tune". I give the old Hilux a boot up the ass once a week up the hill on the way home, holding it at 4,000rpm for about 15 seconds.

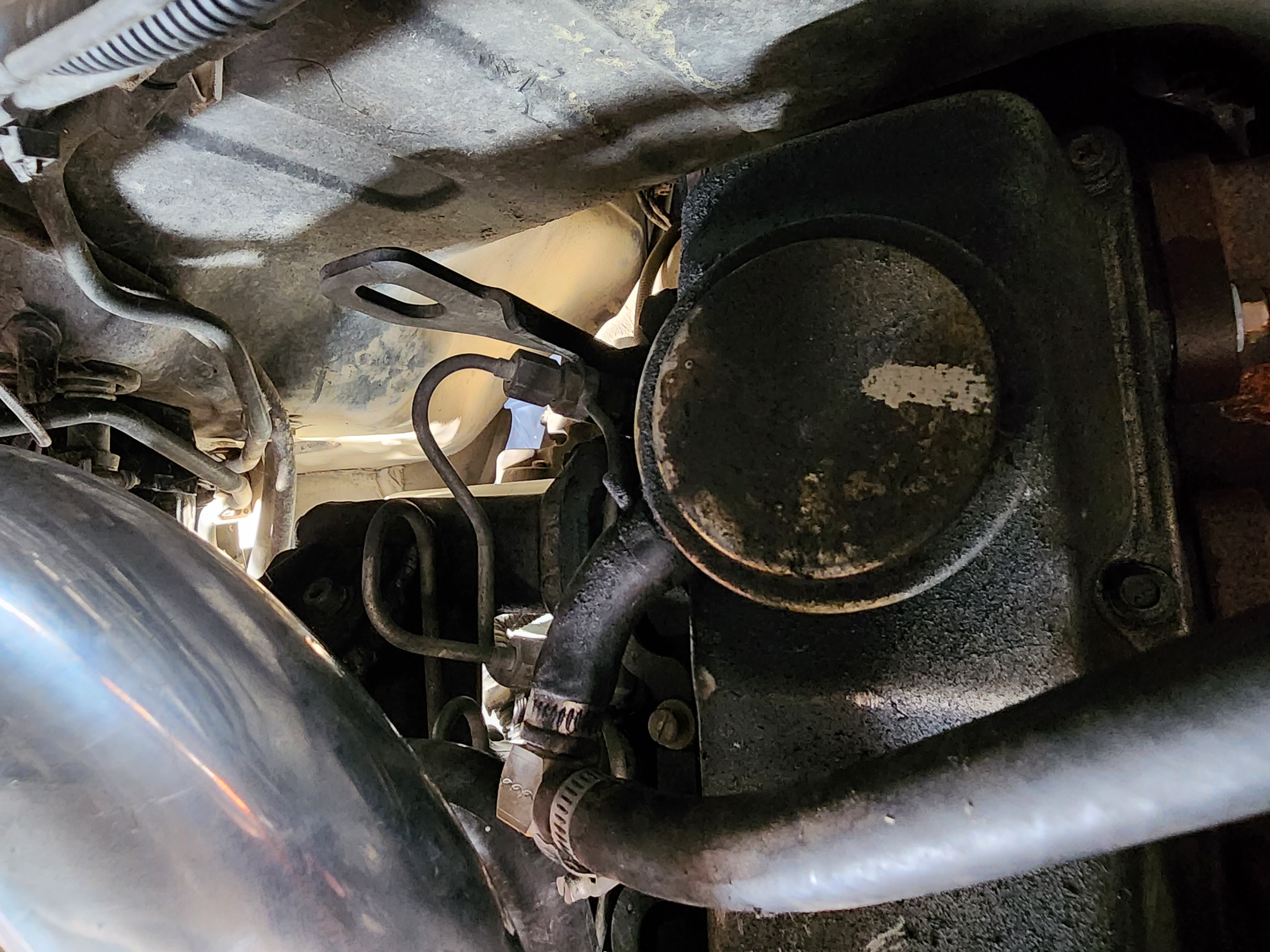

EGR valve as it came off the vehicle:

A better view of the soot deposits:

Lightly pulling one of the wife's cutlery around the inside of the valve:

Better view of the removed soot on one side:

The soot is really soft and crumbly and comes right off with zero mechanical effort. A couple of passes of the kitchen knife yields a pile of soft soot. The elbow is still on the vehicle and doesn't show any difference in texture or hardness. I'll take it off tomorrow and clean it and the EGR up properly. On this evidence, there's no need to remove the intake manifold.

The lesson is that a catch can will stop the hard deposits forming that build up layer by layer over time and cause the severe restrictions. There's not much in the way of evidence of this out there - what there is is a lot of guys arguing without any evidence. So if you want to see what a catch can does over a decent mileage, now you know.

Cheers

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 23

-

24-04-2024, 08:40 PM #1

Provent 200 outcome after 150,000km

Last edited by Flyblown; 24-04-2024 at 09:05 PM.

Just...say...the...word

-

-

24-04-2024, 09:30 PM #2Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 6,198

Thanks, interesting. Have seen similar results in the marine and stationary engine applications, I have been disconnecting the crank case breathers and fitting various types of catch or diversion systems to prevent the issue you describe with varying levels of effectiveness as some of these engines require something about 6x the size of the provent system if not more. Some of these engines ended up with a setup the size of a 40L container to baffle and condense the oil vapour out effectively. Effects of blowby ingestion are a lot more visible on a marine or stationary engine where you can see exactly what is happening when the engine is running - mostly in the intake filter turning black...

I'm also about to do this to my ranger ute, having decided to retain it rather than replace as it's about $10,000 cheaper to run in fuel burn cost only per 100,000Km than the equivalent vehicle with a 6-speed automatic transmission. That will be getting the DPF sorted, the EGR blanked (have investigated this closely and it is the recommended option for the ranger engine partially due to the fact that the cooling system is routed through the EGR valve, deleting the EGR setup allows you to blank the EGR cooling system off as this is a known weak point that will cook the engine if it fails). Also the vane oil pump replaced with a gear pump. As well, the injectors pulled and tested and any issues sorted (injectors replaced if needed) as we just pulled the pressure sensor off the common rail and found it to have been fouled by the factory thread sealant with crumbly debris jammed in the end of the sensor! Not ideal, not sure where else the failing sealant might have traveled too... I had a camera up the manifold through the EGR, and have not seen much in the way of buildup of any sort - evidence of more hot running than short trips.

-

24-04-2024, 10:45 PM #3Member

- Join Date

- May 2012

- Location

- Sydney

- Posts

- 1,826

Iíve got the same motor 1KD in a Prado, 2007 model. It took 350 000 kms before I lost power on the hills and had to pull the intake manifold off and clean it.

Put a catch can on then.

You need a lot of build up before it is noticeable.

Sent from my iPhone using Tapatalk

-

24-04-2024, 11:42 PM #4

The amount of buildup varies greatly @Dicko. I first became aware of this in the workshop at the Superpit in Kalgoorlie where I used to work. I was friendly with the mechanics in the LV Workshop (always a good idea) and they showed me a bunch of early 1KD intakes in the first batch of KUN26R Hilux. They did this job on all those vehicles. They were mostly around the same mileage as mine, but 99% of it was low speed running within the pit operations. And a lot of idling hours. So the air mass is moving relatively slowly through the intake system and it just assists the deposition of the oil/soot mixture.

They looked like this:

Not good.

Vehicles that are run on faster longer trips as the majority of their mileage will generally experience a lower rate of deposition. The flipside is lots of town driving. This is the elbow behind the EGR valve from a 500,000km 1KD used as a delivery vehicle:

This evening I cleaned the throttle body, valve housing and elbow. Took me 10 minutes with brake cleaner and a toothbrush. The dry soot comes straight off, most of it you can wipe off with your finger. Easy as. I ran a small wire brush around the top of the manifold opening and vacuumed out the soot. Then I stuck my borescope into the manifold and it really doesnít look too bad at all, really pleased. Certainly nothing as ghastly as the manifolds that have not had a catch can.

What this has confirmed is the importance of regular oil changes because this soot gathering in old oil is no good. OEM filter and shorter oil change intervals are the go for an eventual high mileage engine.Just...say...the...word

-

25-04-2024, 12:43 AM #5Member

- Join Date

- May 2012

- Location

- Sydney

- Posts

- 1,826

My manifold had the ultrasonic clean. Turbo solonoid actuator thingy gave up soon after and I had to replace the turbo.

Is a bit expensive if you pay someone to do it for you.

Goes like a cut cat again now and fuel consumption is back at 10 l/100 from 12 ish for a mix of highway and city cycle driving. Quite good for an old car with steel bar, winch, lift and slightly larger tyres.

Sent from my iPhone using Tapatalk

-

25-04-2024, 07:32 AM #6Member

- Join Date

- May 2018

- Location

- Queenstown

- Posts

- 2,074

Wow thats impressive!

I'm glad I did a egr delete and catch can from new

-

25-04-2024, 10:53 AM #7Cole

- Join Date

- Aug 2019

- Location

- Dannevirke

- Posts

- 367

Good write up, good to know the provent works well with a long test. Cheers

-

25-04-2024, 11:16 AM #8Member

- Join Date

- Jun 2015

- Location

- christchurch

- Posts

- 18,623

we had a mitsi triton with the 4d56, carbon buildup was an issue. after cleaning it all out i fitted a 5k6 resistor in series with the intake air temp sensor. this caused the ecu to think the air temperature was 0 celsius and turned off the egr valve

-

25-04-2024, 12:13 PM #9

I was a member of a 4WD club in Kalgoorlie for 6 years. We did lots of weekenders out into the bush, I was driving the work Prado V6. Most of the guys were modification fanatics and spent a lot of time and money fiddling with their trucks - mostly Land Cruisers, Patrols, Hilux. I’ve stayed in touch with some of those guys and over time they have upgraded and are now onto some pretty wicked builds with later model vehicles.

The reason I did not do the EGR delete either electronically or by a blanking plate is because some of my Kal mates have experienced quite serious problems with the motors running too hot, due to the ECU not being able to work out exactly what mixture it should be running for the conditions. Now I am no expert in this, but my bottom line is that I don’t want my ECU to be fooled into not controlling combustion optimally for the conditions.

What I learned from trained Denso technicians is that under certain conditions (temp, throttle, load) the motor is expecting to increase EGR to reduce the amount of oxygen in the burn and hence reduce the combustion temperature. I want the motor to be able to get exactly what it wants, when it wants it. I don’t want it to be tricked into running the wrong mixture especially when the engine is working hard, like towing, in hot Aussie weather. Especially on the kind of Nullarbor runs we used to do. It never felt remotely right to me, running an engine under load over 1000 km in hot conditions without the right ECU inputs.

There was certainly no way I was going to take off around Australia towing a camper trailer with a brand-new engine that was being fooled into running the wrong mixture just for the sake of a bit of soot. We did 66,000km on that trip and it went without any technical problems, which certainly wasn’t the case for a couple of the Kal guys who took off in 4WDs tuned for crazy power and torque and of course with EGR deletes. Excessive combustion temps cooks the oil and causes sludging and lubricity problems. The bottom ends of these motors do not like that at all…

Yesterday was the first time I’ve cracked anything open on that engine at 150,000km and I was delighted with how easy it was to give the intake a simple service. (It’s all back together now and running perfectly.)Just...say...the...word

-

25-04-2024, 03:43 PM #10Member

- Join Date

- Nov 2023

- Location

- Christchurch

- Posts

- 546

I'm a Nissan Safari owner, 1991 TD42 silver top so don't have to worry about egr delete etc. I'm on my 2nd Safari and have owned this one since 2007.

In 2012 I put a UFI 18G turbo on it, raised inlet manifold, Cross Country top mount intercooler, 12mm fuel pump, Provent 200 catch can and a couple of other drive train goodies. It's been running 30psi since 2012.

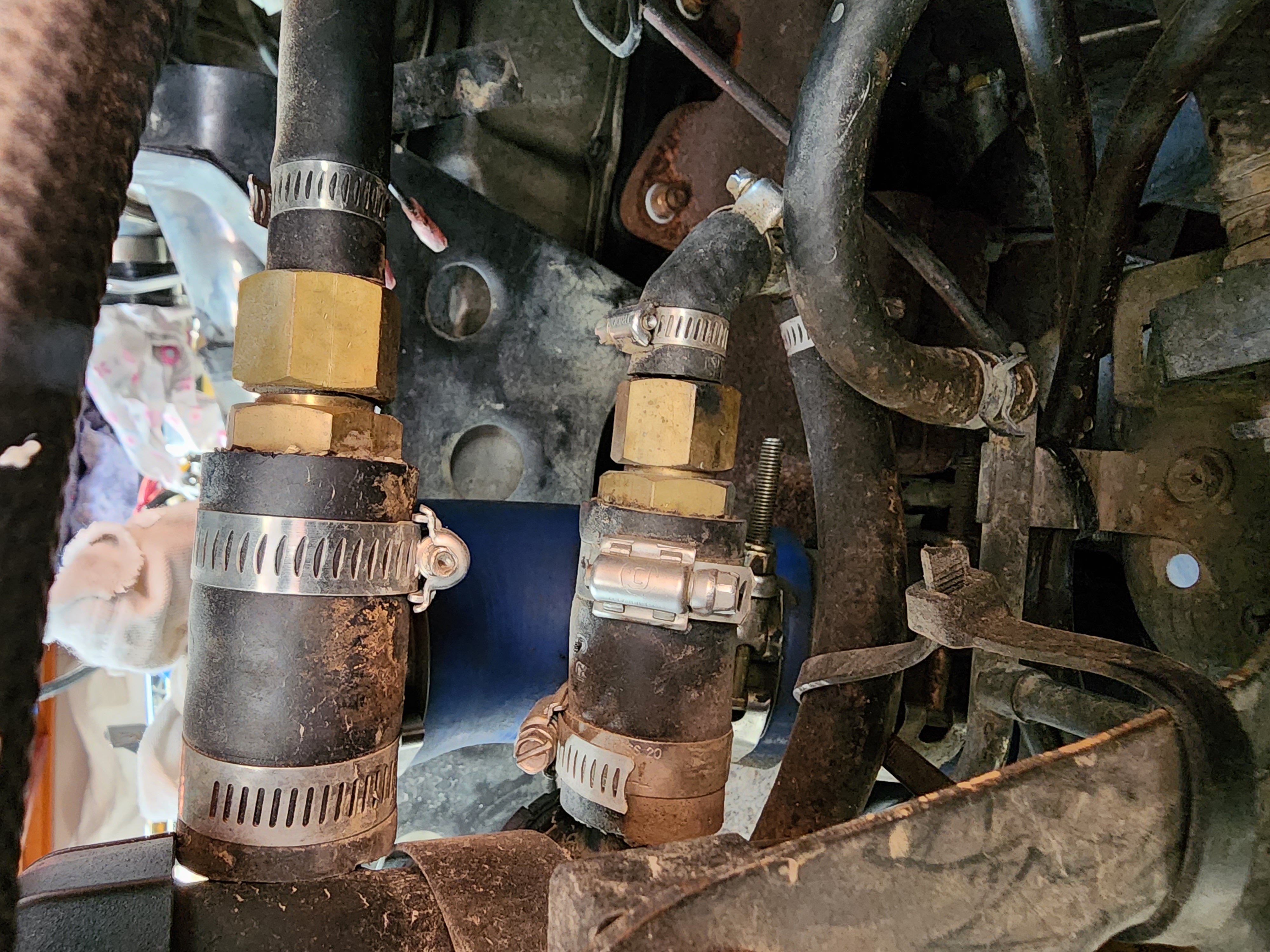

The Provent 200 is designed for 25mm input/output connections, because the TD42 rocker cover outlet is factory a lot less than that I made the mistake of necking down the hosing between the Provent 25mm and rocker cover outlet of 13-16mm or something like that.

End result is that I've had an issue with oil splatter out the exhaust over the last 2yrs, the original UFI turbo had extensive baked oil in the outlet housing, I had a new turbo fitted and the 'splatter' out the back remains to the point where my Safari is now with my son's mate whom is rectifying the hosing to 25mm from the rocker cover breather to the Provent inlet, and same from Provent outlet to pre turbo inlet. If I still have oil residue out of the exhaust and over the arse end of the truck then I have to consider potential valve stem seals or deeper problems within the engine as advised by mechanics.

My suspicion is given independent info that I had the Provent 200 set up incorrectly.....I hope that's the bloody case cos things are going to get expensive if the issue is engine related. The TD42 still pulls and performs like a freight train regardless. I'll report back if the issue does relate to the Provent being incorrectly plumbed by myself.

-

25-04-2024, 04:53 PM #11

@Twodiffs

How could necking down the hose cause a problem when the inlet to the can is bigger than the outlet from the rocker cover? If it was the other way round then I could understand an increase in pressure but you are reducing pressure. Smaller diameter out, bigger diameter in.

The Hilux crankcase vent outlet on the rocker cover is 16 mm. The kit comes with a single hose that is 16mm at the outlet end and 25mm at the Provent 200 inlet end. The inlet is the upper of the two connections.

The outlet of the catch can is the lower connection and that is also 25mm. That connects to the turbo inlet with a 25mm hose.

The Provent has a pressure release valve in the cap. If crankcase ventilation pressure coming into the can cannot be pushed through the filter and out into the turbo, then it exits through the cap. The spring controlling the release valve is surprisingly weak and it only takes a gentle press of the finger to open the valve. So you don’t need much pressure for the catch can to start venting to atmosphere.

One of the criticisms of catch can is that they can cause excessive back pressure into the crankcase and blow seals. I don’t know anything about other designs but it’s impossible with the Provent 200. I know for a fact it will vent to atmosphere if the filter starts to get too blocked to work optimally, because I let one of my filter service intervals go too long and I noticed an oily residue around the top of the unit. That release valve was doing exactly what it’s designed to do.

I’m not sure how you could get the plumbing wrong? In at the top side connection and out at the bottom side connection, with the captured oil training out of the very bottom into a length of hose, from which I periodically drain it into a bottle. (Some guys have a connection that drains the oil back into the crankcase.)Just...say...the...word

-

25-04-2024, 06:30 PM #12Member

- Join Date

- Nov 2023

- Location

- Christchurch

- Posts

- 546

Through connecting it like this I've gained nothing and actually prevented the Provent from working as efficiently as it should. It should be 25mm hosing from the rocker cover outlet all the way to the Provent inlet, and the same from the catch can outlet to the pre turbo inlet.

-

25-04-2024, 07:47 PM #13Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 6,198

Ahhh, I see what you mean. The 16mm from the rocker cover is not the issue - each of those DR brass fittings reduces the hole size down from the 16mm thin steel outlet tail on the rocker cover (and the 5/8 bore hose) down to about 8mm through the threaded BSP sections of those 5/8 hosetails. Adding in multiple of those fittings in the system is a lot of section where the throughput of vapour has to accelerate and then decelerate to get the volume of gas flow through the fittings. That will add a lot of resistance and flow losses to the system leading to the experience you have had where the relief valve in the filter can do nothing to help you as the restriction is in front of the catch can body.

Plumbing in ahead of the turbo should actually provide a small amount of assistance by reducing the pressure on the outlet side of the catchcan a little below ambient pressure, but it won't be much. Should work to balance out the filter element in the can though...

As Flyblown suggests with the factory supplied connection kit without the step up/down brass fittings, there won't be any of the additional restriction in the setup.

-

25-04-2024, 08:20 PM #14

@Twodiffs there's some really good reading on the aussie patrol forum about what you describe. Old Mav on there explanes about the volume of crankcase pressure on a boosted TD42 being close to 200L per minute, which a Provent 200 is designed for. Theres pictures of a custom rocker cover vent with 25mm outlet.

I've got same truck as you but running way less boost (10psi) due to no cooler. I've got a bit of sneaky oil issue too & I think it's related to my cheap Chinese catch can. So I'm going to by pass it to see if it fixes the issue.

Sent from my SM-S906E using Tapatalk

-

25-04-2024, 08:35 PM #15

We have plates and egr deletes in both our hilux and cruiser and both previous hiluxes

While I'm certainly no expert at all I'm not sure your information is correct but happily to be proven wrong

The egr is only open on idle. It's never open when trying to make power.

It can't be you need make exhaust manifold pressure to create boost.

Sent from my SM-S916B using Tapatalk

Similar Threads

-

A happy outcome for the old Lachmiller Press

By Jhon in forum Reloading and BallisticsReplies: 3Last Post: 24-05-2023, 08:38 PM -

2,000,000km on the clock

By Flyblown in forum Outdoor TransportReplies: 27Last Post: 01-04-2022, 02:05 PM -

55,000km 4.5 year oil change

By Beetroot in forum Outdoor TransportReplies: 29Last Post: 12-09-2017, 06:06 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

25Likes

25Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks