Part 5 - Regulated and Non regulated stoves.

This applies to upright canister stoves from part 2.

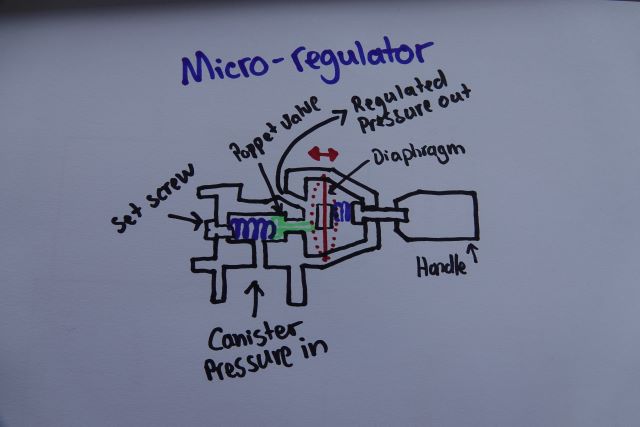

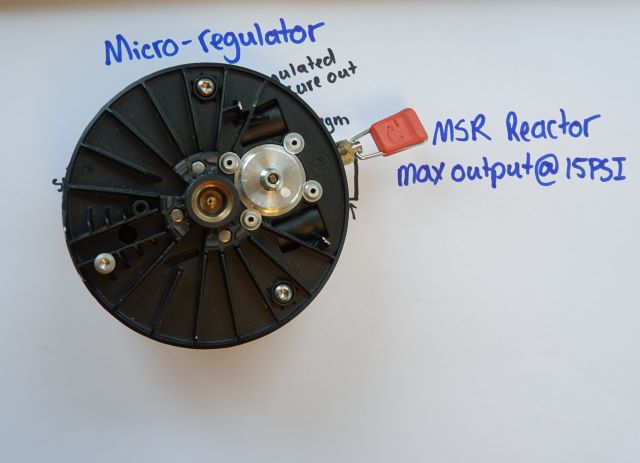

The two stoves shown both use a different type of valve to control the flow of fuel to the burner. The remote canister stove shown has what is called a 'Micro-regulator' while the other uses a basic needle type valve.

A micro-regulator stove will regulate the pressure supplied to the burner automatically so as the canister cools (evaporative cooling remember) the output will remain constant. That's quite handy. It means if we're using the stove at half throttle as it cools we don't have to manually open our valve more and more to keep the output the same. Each different brand will use a construction of their micro-regulator but I've drawn/copied a rough example above.

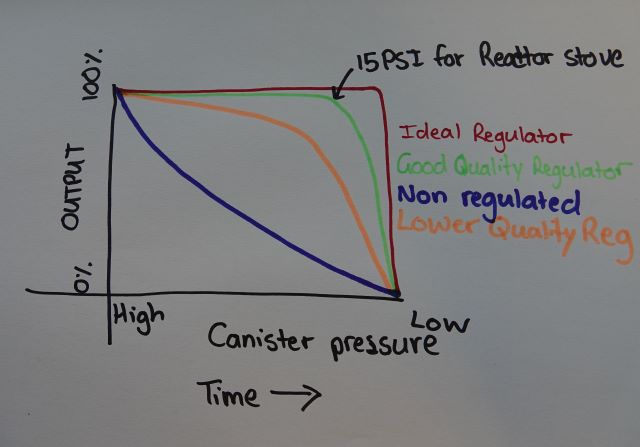

I have here an MSR Reactor stove, it's a micro-regulated type. MSR says it runs on max output at 15PSI. So we need at least 15PSI inside our canister to get full output from this stove. That's the limitation of a micro-regulator. Once our canister pressure falls below this pressure our micro-regulator stove is no better really than non-regulated upright canister stoves.

I've included another rough sketch based on MSR data to illustrate this.

Micro-regulators are great but just be aware they're not the be-all end-all of solving upright canister stove issues.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 54

Thread: All about gas stoves.

Hybrid View

-

12-04-2020, 03:25 PM #1

Similar Threads

-

Vargo Ti Triad/Triad Multi-Fuel Stoves

By Nesika in forum Gear and EquipmentReplies: 8Last Post: 10-03-2016, 10:56 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

67Likes

67Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks