So the boys who have been coming around to my shed on a weekly basis to build stuff decided that they wanted to grind knives for their next project. That forced me into doing some homework on materials and techniques that I could teach them, and meant that I had to be building a knife one week ahead of them so that I could give them some do's and don'ts.

As they say - knife makers don't make mistakes, they just make smaller knives.

So last week I finished making my one, and most of the boys are in the final process of handle shaping.

For simplicity of heat treatment, we chose to use 1075 steel. For my knife, I bought in some green micarta handle material and some mosaic pin in from Aliexpress, and I bought a steel stamp from Esty for my 'makers mark'.

I ground out a drop point from 3mm material, convex grind, finished to about 400 grit and left 'as heat treated'. Did two temper cycles which by the tables should leave the blade at 60HRC plus/minus one or two.

I decided early on that this knife would be for my older brother for Christmas, and since sharpening is a personal thing and you tend to have your own angles I've left the blade unsharpened for him to complete. As an added extra, my younger brother did his first ever leather sheath build, which I think came out bloody well.

The 'blemish' on the blade in the photo is where the hot blade melted the paint on my magnet that I was using during the heat treat. Its not a defect in the blade.

Close up of the makers mark and the mosaic pin, and the sheath before waxing.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 16

Thread: First ever knife grid

-

16-12-2018, 05:05 PM #1

First ever knife grid

-

-

16-12-2018, 05:25 PM #2Member

- Join Date

- Mar 2014

- Location

- Tauranga

- Posts

- 3,030

Turned out good man. Be a great little user. What did you shape the bevels with?

-

16-12-2018, 05:31 PM #3

Sorry, is this your first go at knife making? Either way it looks fantastic. Great shape with a very nice finish. Kudos to you. I would think that knife would sell in any knife makers repertoire.

The range of what we think and do is limited by what we fail to notice. And because we fail to notice that we fail to notice, there is little we can do to change; until we notice how failing to notice shapes our thoughts and deeds

-

16-12-2018, 05:32 PM #4

-

16-12-2018, 05:59 PM #5OPCz

- Join Date

- Jun 2012

- Location

- Nor West of Auckland on the true right of the Kaipara River

- Posts

- 34,744

Well done.

It takes 43 muscle's to frown and 17 to smile, but only 3 for proper trigger pull.

What more do we need? If we are above ground and breathing the rest is up to us!

Rule 1: Treat every firearm as loaded

Rule 2: Always point firearms in a safe direction

Rule 3: Load a firearm only when ready to fire

Rule 4: Identify your target beyond all doubt

Rule 5: Check your firing zone

Rule 6: Store firearms and ammunition safely

Rule 7: Avoid alcohol and drugs when handling firearms

-

16-12-2018, 08:53 PM #6Member

- Join Date

- Mar 2017

- Location

- christchurch

- Posts

- 167

sweet little knife, can't believe it's your first one. How did you do the makers mark??

-

16-12-2018, 09:31 PM #7

Yes, first attempt at knife making.

Bevels were ground with a belt grinder.

Makers mark was with a steel punch that has the symbol or logo engraved into it. Was about $60NZ landed from the USA.

Heat treat was with a forge made out of two 9kg lpg bottles running a carburising flame to prevent blade oxidation and quenched in canola oil. Tempered in a bench top oven which was surprisingly accurate in holding temp. Would be keen to get an actual hardness test post tempering. I was targeting 60HRC.

YouTube was my friend for tuition before undertaking each step.

-

17-12-2018, 12:38 PM #8Member

- Join Date

- Nov 2018

- Posts

- 4

Great First knife

I’m gonna be making my first proper knife this holidays since I’ve finnaly got my charcoal forge built and my workshop/tools set up. I have made a few practice blades just to figure out the basics but didn’t take any to seriously so if they bent or warped I wouldn’t be to sad.

Few questions I’ve got

What type of belt grinder do you have eg: 2x72, 4x36, homemade, brought

Also how long did u temper the 1075 in the oven for(time/tempature)

I didn’t really know there were any beginner knife makers in NZ so this made me happy seeing I wasn’t the only one.

Any Knifemakers a few hours from levin?

-

17-12-2018, 02:05 PM #9

very nice indeed, well done!

Regards

Terry

https://www.knives4africa.co.nz/

Custom knife dealer

Authorised Nitecore Torch Retailer

NZ Distributor of Nano-Oil

-

17-12-2018, 03:26 PM #10

Awesome mate, im very impressed.....

While I might not be as good as I once was, Im as good once as I ever was!

While I might not be as good as I once was, Im as good once as I ever was!

Rule 4: Identify your target beyond all doubt

-

17-12-2018, 04:48 PM #11

I bought a Radius Master a year or so ago which is a 50x1220 which I have been using for general grinding duties as I don't have a bench grinder. Its a very versatile machine due to the rotating head and roller cassette which allows you to flat grind, slack grind, or used any of the various size rollers. https://www.machineryhouse.co.nz/L096

Its not a cheap grinder, but very versatile. I've been getting my belts from PPS in Auckland.

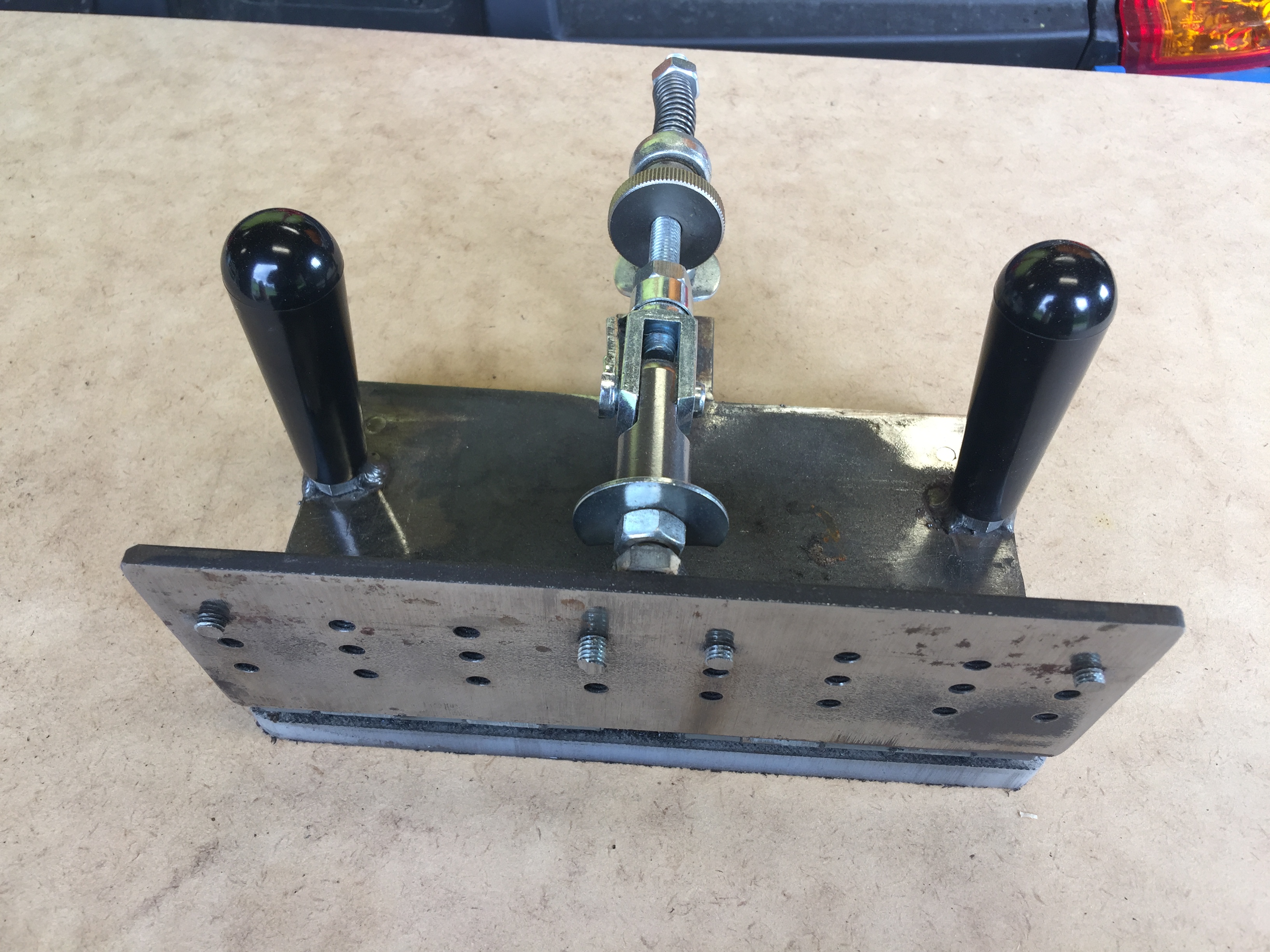

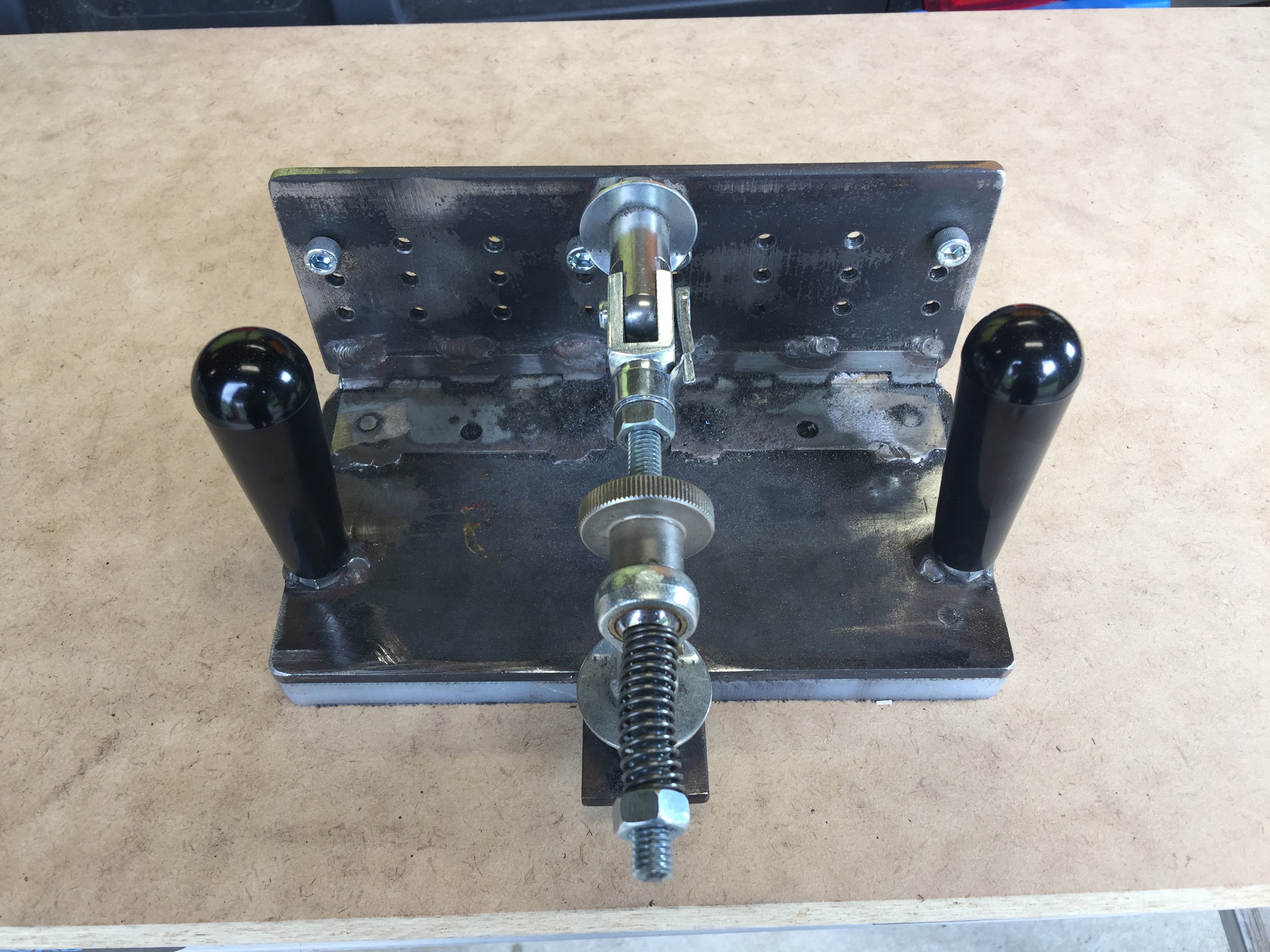

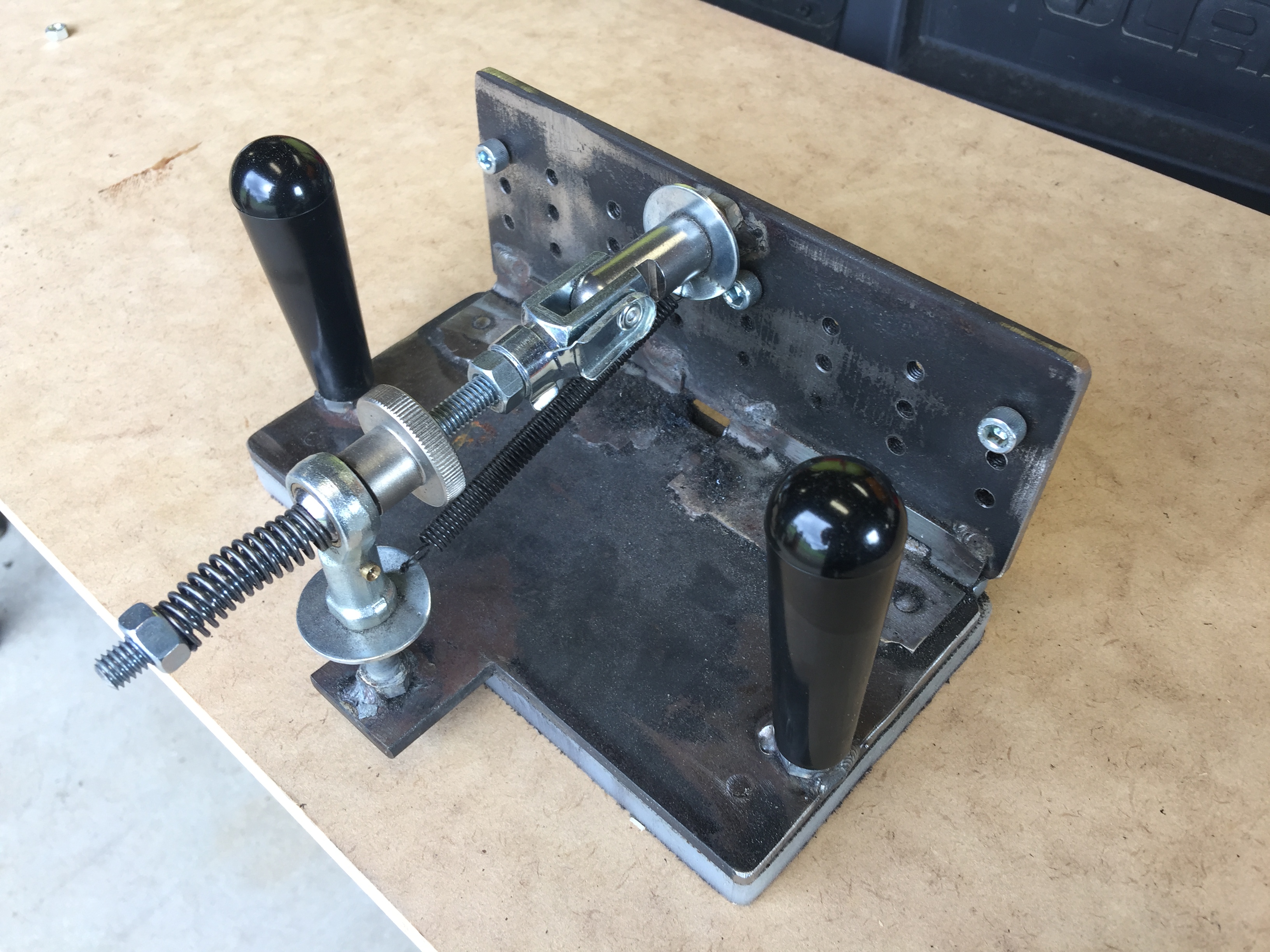

I made up an extension to the little table that comes with the grinder to give a bigger work surface, and then made up a grinding jig so the boys could do accurate flat grinds. I'll post a picture tonight.

I tempered the 1075 twice for two hours each with the oven bouncing between 210 and 220 deg C

-

17-12-2018, 05:43 PM #12

Here's the grinder with the table extension which just clamps over the factory table and his held in place with a couple of bolts. Its 75x6 flat bar.

And here is the grinding jig for flat grinding

-

18-12-2018, 12:54 PM #13

nice i could test the hardness if you want

cheers john

-

18-12-2018, 09:41 PM #14

-

19-12-2018, 08:31 AM #15

Some inspiration. These guys of course can't afford personal protective equipment so let's not criticise that aspect.

An itch ... is ... a desire to scratch

Similar Threads

-

App to calculate grid references

By Robojaz in forum ShootingReplies: 8Last Post: 06-05-2016, 08:07 AM -

New Zealand Off Grid Living And Homesteading

By Alaskaman 2016 in forum HuntingReplies: 29Last Post: 27-11-2015, 05:35 PM -

making a knife and a sheath part 6 - knife done, sheath musings

By Shelley in forum Gear and EquipmentReplies: 2Last Post: 27-07-2015, 01:19 PM -

iPhone grid ref app

By chrome in forum Gear and EquipmentReplies: 9Last Post: 04-01-2015, 12:29 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

21Likes

21Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks