Does anyone know where I might find Boxford lathe parts? I picked up an old 9inch one in pretty good nik with the intention of getting into some hobby machining, although it's new to me as my school never had metal work. Any way I noticed one of the gears in the head is missing 2 teeth. It doesn't jump but I guess it's loading up the tooth behind it rather than load sharing. I think it's a back gear and has what appears to be 2 share pins in it. Obviously they didn't do what they are sposed too. Before I try to get it built up and hardened I was hoping to find a replacement. I understand these are the ones that schools used to use so hopefully fairly common?

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 38

-

10-11-2020, 08:49 PM #1Member

- Join Date

- Jul 2015

- Location

- Nelson

- Posts

- 387

Lathe

-

-

10-11-2020, 09:49 PM #2Member

- Join Date

- Jul 2015

- Location

- Nelson

- Posts

- 387

Thanks. Will keep an eye out

-

11-11-2020, 12:20 PM #3

I think you'll find that the pins aren't intended to be shear pins at all - they're drive pins that are engaged or disengaged depending on whether you're using the reduction back-gear. The detail of this apparently changed between the earlier and later Boxford's (I have a CUD model with the later backgear arrangement).

Lathes.co.uk seem to sell a replacement ring-gear to install over the existing gear hub, costs 75 pounds excl. shipping. Trademe currently has a listing for a Boxford bull gear, but I don't know if it suits your lathe?

-

11-11-2020, 07:10 PM #4Member

- Join Date

- Jul 2015

- Location

- Nelson

- Posts

- 387

Mimms2. You obviously haven't seen my welding!lol . Would only attempt if I had a spare before I made it beyond fixable

PaulNZ. I have asked the trademe man and waiting to hear back. Not knowing much about lathes and engineering full stop. My description may not be accurate. This gear is held by those pins against the drive pully. You move a second shaft with two more gears on a cam shaft over with a lever to engage this and or another gear. What makes me think they are share pins is they are not solid but hollow and you can see small splits on one end of each as though they almost shared off but I'm guessing a tooth was lost first. But as I say just a guess. Yes that UK site looks promising if I can't sort it locally.

Thanks guys

-

11-11-2020, 08:18 PM #5Member

- Join Date

- Jul 2015

- Location

- Nelson

- Posts

- 387

Yes not a big gear and welder mate is screwing nose up, but will step up if I can't get another( he just doesn't know it yet) Want to do a bit of thread cutting so slow stuff ups cause less problems than fast.

Not like any roll pins I've seen. The half that sits in the pully part has no splits yet the other half has 2 or 3 that look stress related. Not the usual full length split on standard pins. Also very lite weight. Or are these special ones used in a lathe?

-

11-11-2020, 09:15 PM #6

Drive pins on mine are definitely not hollow for what it's worth- I just checked. Mimms - min speed without backgear is 210rpm. Not saying it can't be done, but I appreciate the backgear on mine when threading to a shoulder! Also nice to drop the speed when parting tough material sometimes.

Edit: I should say not hollow on the front face. They may have blind hole in the back where the compression spring sits - I can't remember without pulling them out.

-

11-11-2020, 09:38 PM #7Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,374

I have a full set of gears for a Herbert, Aussie lathe, were they a knock of the Boxford? I don't know, but maybe a gear that fits?

Boom, cough,cough,cough

-

12-11-2020, 09:15 PM #8Member

- Join Date

- Jul 2020

- Location

- Central North Island

- Posts

- 5,286

Jeeze, minimum speed on mine is 37 rpm

-

12-11-2020, 10:22 PM #9

Poor choice of words in my part - should have said 'near'. Definitely a fan of relief grooves. Also got to bear in mind that there's no spindle brake in these lathes and most also have imperial leadscrews, meaning you don't really want to disengage the carriage at the end of a cutting pass if cutting metric threads. Add those together and you want to thread slow unless your thread relief groove is really wide. Or thread upside down and away from the shoulder if you like.

-

13-11-2020, 07:16 AM #10

I had a broken tooth on my Grayson lathe's 25-teeth screw cutting change gear. I replaced it with a stick weld blob filed down. Tedious filing... and the weld proved tougher to file than the surrounding cast iron! "Next time" I will file a groove in place of the missing tooth and get someone to build up some brass solder for me to shape. Plenty of strength in brass.

*** VERY important to use files with a blank/inert side to avoid damaging adjacent teeth, if you don't have those, create one with your bench grinder by smoothing one side of a file. An extra file is easier to buy than a Myford cog. ***

Don't have to run the lathe to listen for noise, you'll feel for the fit as you roll the repaired section of the cog against another by hand. Once the repaired rolls no different than the rest you're there.An itch ... is ... a desire to scratch

-

13-11-2020, 07:32 AM #11Member

- Join Date

- Jul 2020

- Location

- Central North Island

- Posts

- 5,286

Was lucky enough to pick up a 1951 Colchester Mascot cheap a few years ago. Same model I learnt on during my apprenticeship in 1979

Would turn Cat D8 idlers for rebuilding bearing journals with ease. 29" diameter max swing

Would turn Cat D8 idlers for rebuilding bearing journals with ease. 29" diameter max swing Once you own a three phase diesel generator the worlds your oyster with all that cheap second hand three phase gear out there

Once you own a three phase diesel generator the worlds your oyster with all that cheap second hand three phase gear out there

-

13-11-2020, 03:29 PM #12Member

- Join Date

- Jul 2020

- Location

- Central North Island

- Posts

- 5,286

Gap, but never taken out. Was in a corrections facility for donkeys years, then a guy picked it up for his trucking business and got used twice a year to fix stuff, then I picked it up. Can't lift 2,3 Tonne, so have to build a frame over it each time it gets moved, and block and tackle it up with my bulldozer!

My last one was a Myford super7, and I almost paid for the upgrade when I sold that.

Take a 4mm cut and it makes the Gene get down and boogie, and stand clear of the flying chips

-

14-11-2020, 12:16 PM #13

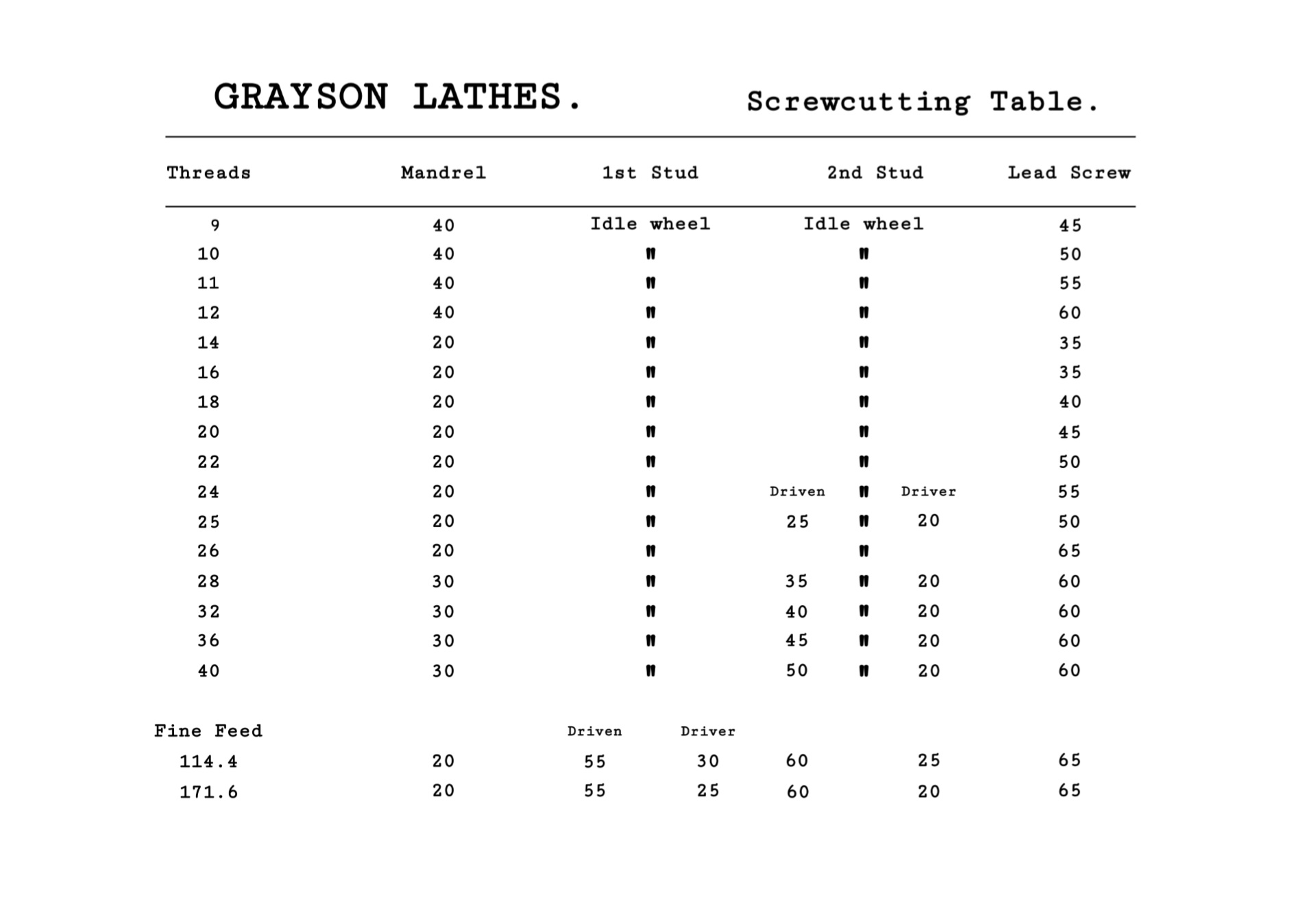

Yes, well spotted! A bit unusual, my lathe also has an unusual 8 t.p.i. lead screw and the gears run from 20 teeth to 65 teeth in increments of five. Playing with online gear calculators indicates you can exactly cut any old thread with the set.

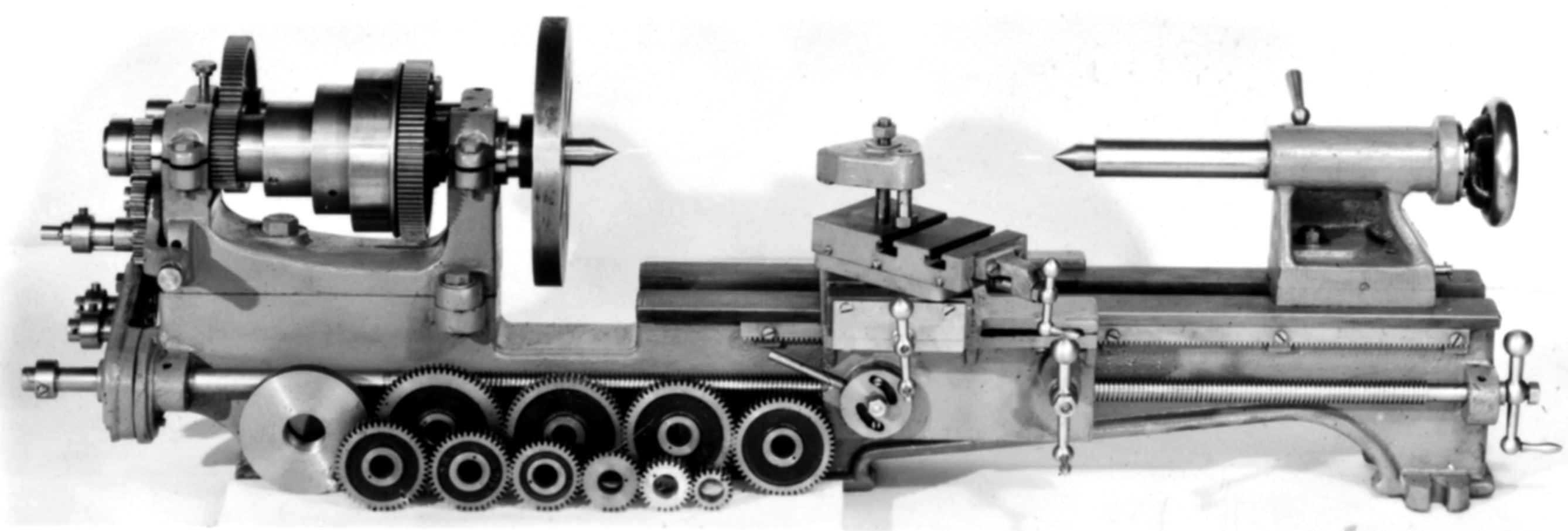

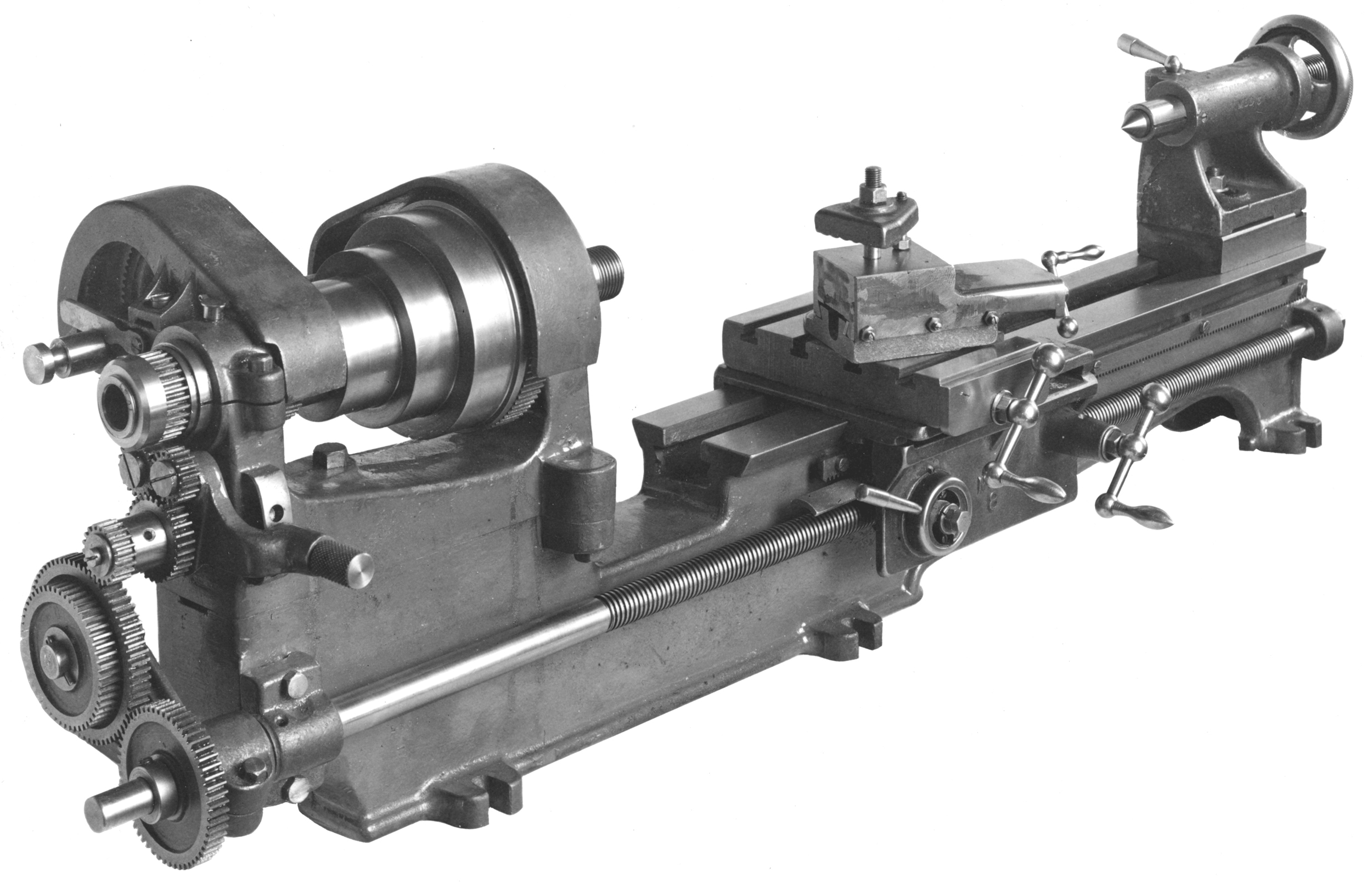

The English Grayson lathe was sold here in NZ branded "Companion" by Johns Ltd in Auckland who existed 1920-22 to 1951 and from ads their batch of 3.5" lathes were sold in the the last 2-3 years of the business. Johns Ltd was primarily a radio gear outlet, "Companion" radio their main brand, they also sold a "Companion" wood lathe, no doubt a rebrand too. The picture below shows one like my lathe with my exact set of change wheels (65,60,55,50,45,40,35,30,25,20). Only thing I'm missing is the dog driver seen here to the left of the 65 tooth gear, the Grayson lathe dogs are straight tailed, not bent tailed, so need a faceplate pin to drive them.

Back to the gears here is a retype of the Grayson change gear chart for the most common threads, this one page instruction was the only manual you got with the lathe and there is some sense in that.

A beautiful BW promotional photo showing arrangement of the thread cutting gears.

Last edited by Cordite; 14-11-2020 at 12:23 PM.

An itch ... is ... a desire to scratch

-

14-11-2020, 03:24 PM #14Member

- Join Date

- Jul 2015

- Location

- Nelson

- Posts

- 387

Have talked to a local gunsmith and he's going to look at the gear for me and see what can be done. Probably get him to cut the acme threads on the screw brass nuts as well since they are pretty worn with a lot of back lash. I did manage to make the new brass nuts as my first project which kept me busy for hrs watching google clips an putting into practice what id seen.

-

14-11-2020, 04:06 PM #15

I can just put a bolt in the bare faceplate to solve that, for a copy of the arrangement in the picture, a worn out 3 1/2" chuck could also donate its back plate with the central mounting threads. Turning between centres... suppose you can turn a precision bull barrel into a pencil barrel...

Yep, need a spanner for mounting but it's pretty quickly done. The lathe is low powered with a 1/4HP saw motor so I just use brass soldered TC tools, a box of eight from China for less than $20 from memory. I was disappointed to find they had not taken care to braze each tungsten cutting bit to the same relative heights on the shanks, so that a single fat shim on the tool holder was no use. So, to facilitate "quick change", I've mounted each tool on a two equal stacks of pocket change from the USA, dimes, quarters, etc. and some washers until the cutting edge was at centre height and epoxied them. I heat hardened the two-component epoxy after it set to limit lateral creep at the expense of some toughness.

From one eBay China seller, image links to the auction page:

Just took a photo of my own humble arrangement. You can zoom in and see the epoxy on the tool bits, it was clear and tough (you could just make a nail mark in it) but on heat treatment turned perspex hard and took on the amber colour. Heat treatment achieved by sitting upside down for 9mins on ceramic cook top on lowest setting and stopped when the paint started to give off subtle visible fumes that my wife calls "smoke". It's given the remaining blue paint a neat retro crackled finish...

Last edited by Cordite; 14-11-2020 at 04:12 PM.

An itch ... is ... a desire to scratch

Similar Threads

-

New old lathe

By gadgetman in forum Projects and Home BuildsReplies: 118Last Post: 18-02-2017, 11:06 AM -

The new cnc lathe has arrived.

By DPT in forum DPT MachinistsReplies: 45Last Post: 17-03-2015, 02:44 PM -

Anyone got a lathe at home

By specweapon in forum Projects and Home BuildsReplies: 12Last Post: 14-07-2014, 09:55 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks