So the other day, at the flea markets I picked up an old rusted chisel, it was $2, too rusted to see the brand name.

I took it home, cleaned it up, got most of the paint and rust off and it turns out to be a Ward and Payne knife, very good Sheffield tool company, eventually acquired by Wilkinson sword. Started in 1803 and become Ward and P in 1850 or so, this one looks to be from the 1950ís which means it was made from A2, which Ward had absolutely nailed the heat treatment for.

However this one showed a distinct lack of care, the grind was off, the edge was chipped and the angle was set at 35 degrees, I personally prefer my chisels to be 25, but I can do any angle.

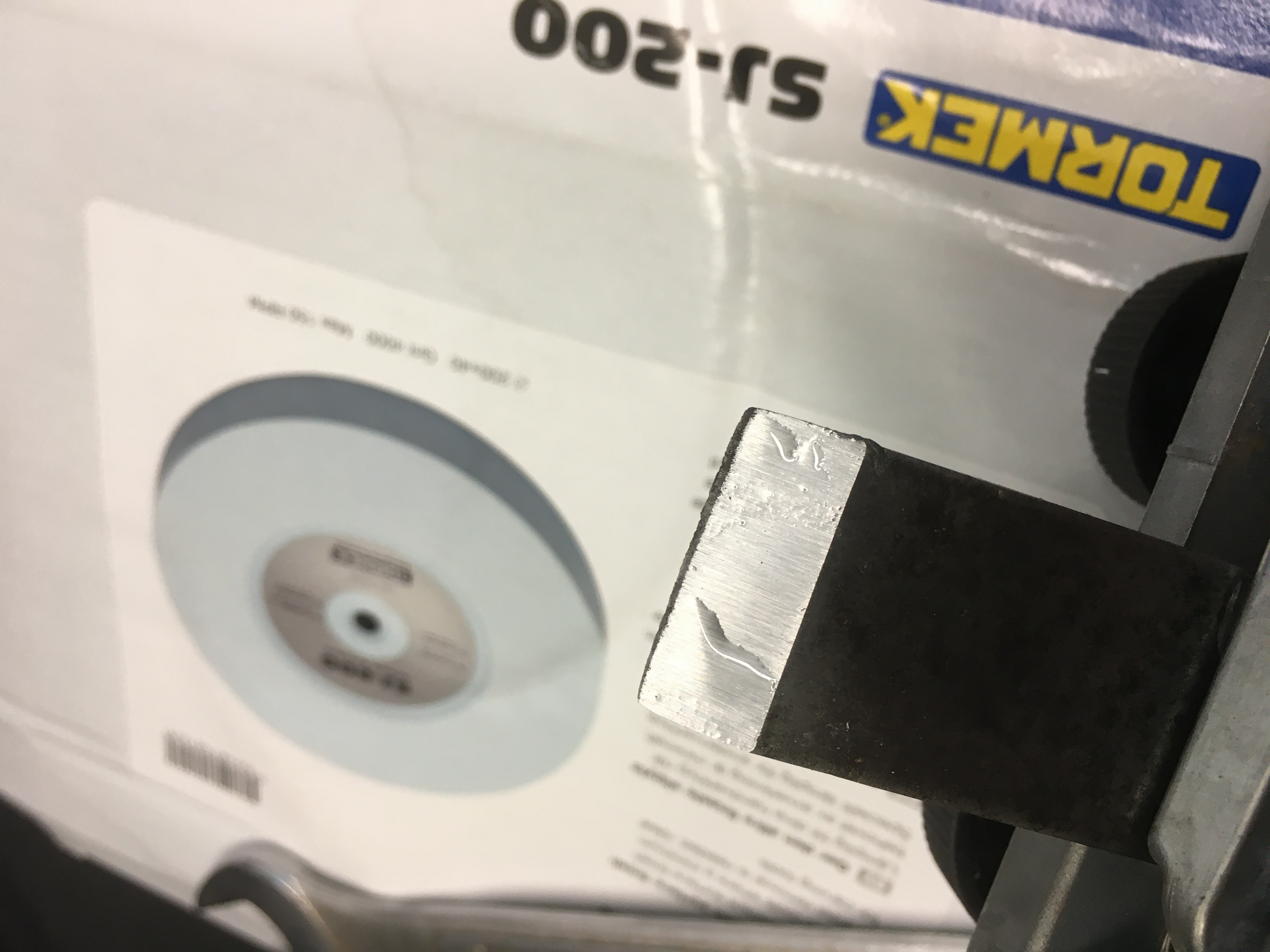

So first I set the tormek at 220 grit and got rid of the damage:

Bit more work at 220 and it was done

Then I switched to 1000 grit and got rid of the worst of the 220 scratch pattern

Tad more work

Then to finish I dropped in a 4000 grit wheel on the tormek

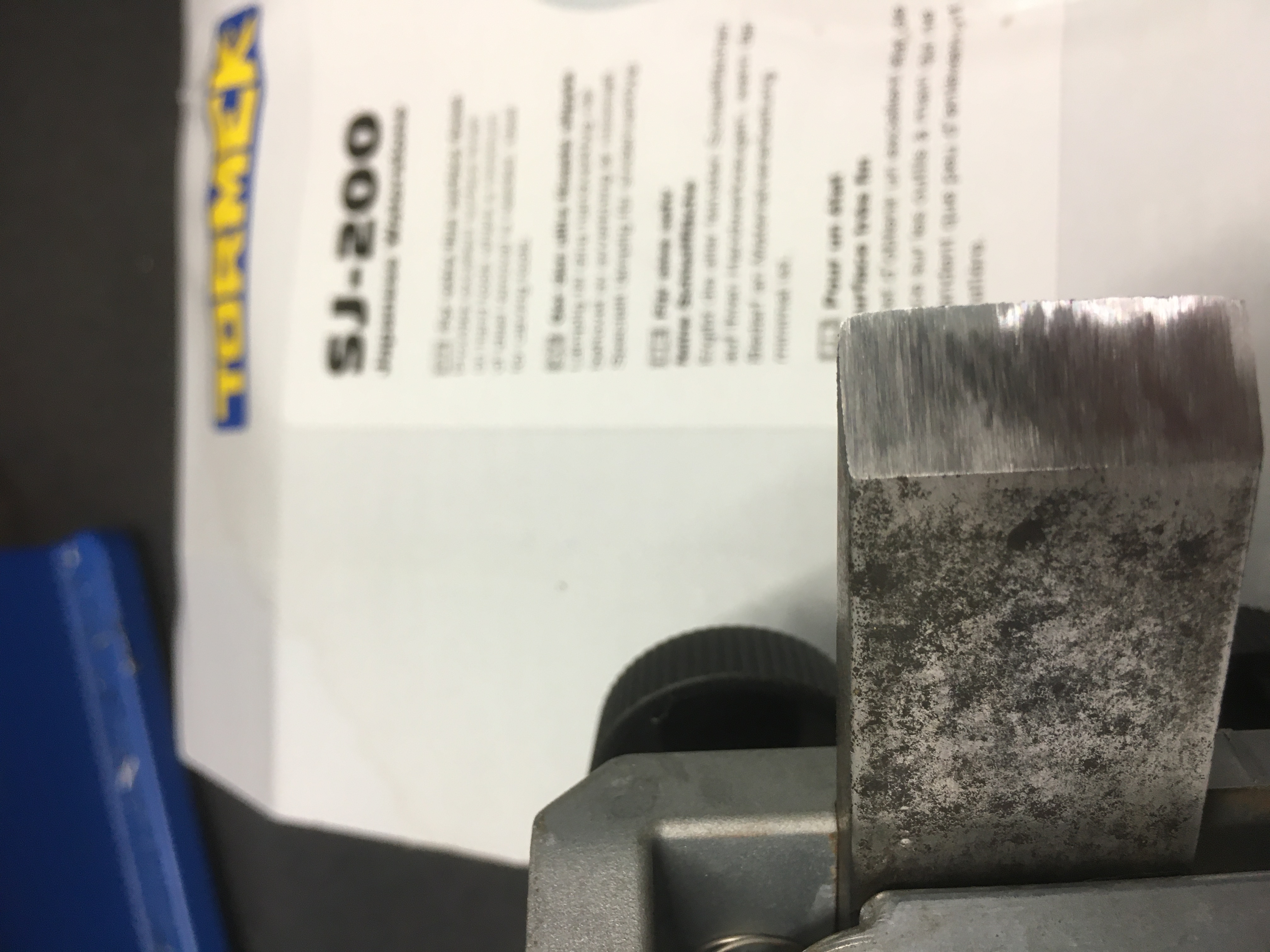

Mirror finish.

Nice and sharp now, bargain at $2.

By the way I sharpen chisels, same price as I do knives, $5 per piece, can do planer blades and scissors too.

Shelley 021727546

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 13 of 13

9Likes

9Likes

Thread: Sharpening a chisel

-

23-07-2020, 06:16 PM #1Member

- Join Date

- Aug 2014

- Location

- Auckland

- Posts

- 719

Sharpening a chisel

-

-

23-07-2020, 07:25 PM #2

I sharpen my working chisels with a slightly shallower angle and always by hand on my oilstone as I have done for 30 years. That is a good looking finish though.

-

23-07-2020, 07:53 PM #3Member

- Join Date

- Aug 2016

- Location

- Gisborne Rural

- Posts

- 3,428

When i was apprentice a older guy offered to take home my chisel's to give them a once over. Always used to carry one chisel in your apron. some how it was that sharp it cut through the leather as i was bending over doing a job and cut into my leg.

-

23-07-2020, 07:59 PM #4Member

- Join Date

- Aug 2014

- Location

- Auckland

- Posts

- 719

What angle do you go for, I have heard some people go for 20 for a hand held chisel, others go for 30 for a hammer hit chisel, I usually set mine to 25 as a happy medium, I can do full flat grinds but have found a slight hollow grind seems to get better results.

I do not round the edges as seems popular overseas but go straight from edge to edge, seems to work well, I can do a slight secondary edge but have never needed to, sharpen a little often seems key to me, but occasionally you need to go back to basics as with this chisel.

I now need to find someone with a lathe to make a new handle.

-

23-07-2020, 08:30 PM #5Member

- Join Date

- Feb 2013

- Location

- Mangakino

- Posts

- 1,855

My old man was a whizz on sharpening chisels.

Had three boys using chisels (translation using as a universal tool for everything).

He just used a oil stone,was pretty good on knives too but left us to do our own the chisels were his.

-

23-07-2020, 08:46 PM #6

NIce, I almost brought a Tormek.

How is the back of the chisel? any pitting?

And did it get a hone on a stone after you ground it?Use enough gun

-

23-07-2020, 08:50 PM #7

Looking good. Did you flatten the back? Polishing pitting out of the back seems to take the most time for me, but without doing that a mirror bevel doesn't translate to an excellent edge.

Edit: 40mm beat me to it...Last edited by PaulNZ; 23-07-2020 at 08:55 PM.

-

24-07-2020, 07:48 AM #8

I don't really know what angle its all just done by eye but it does look shallower than that, mine get sharpened every time they are used, a throwback to working on a joinery bench with the stone to hand I guess. Same with my hand planes constant sharpening, actually need a new blade for my block plane its so worn down. I keep chisels straight with a slight curve on plane irons, a rounded edge chisel would be near useless I reckon.

-

24-07-2020, 08:48 AM #9

-

25-07-2020, 06:25 PM #10

Convex rather than concave I think they mean

-

25-07-2020, 06:38 PM #11Banned

- Join Date

- Mar 2016

- Location

- auckland

- Posts

- 2,453

Nice surprise for $2. Ready for another 80 years at least.

-

25-07-2020, 08:00 PM #12

-

27-07-2020, 08:04 PM #13Member

- Join Date

- Aug 2014

- Location

- Auckland

- Posts

- 719

I do the back with sandpaper on a flat glass plate, wet and dry start with 120 and work my way up to 1200, there is a tiny bit of pitting left now, you can see it but can’t feel it.

My mate likes to round the edges on chisels like people do on planes, said that was just the way he was taught (Aussie), frustrating as hell as I have to go around and fix them all...

Similar Threads

-

Knife Sharpening

By Paua Pete in forum HuntingReplies: 7Last Post: 11-01-2020, 09:36 PM -

Knife sharpening

By ocean-hunter in forum Gear and EquipmentReplies: 13Last Post: 24-03-2019, 10:58 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks