Sharpening a D2 knife blade: some photos, observations, and opinions

I ended up with a couple of small chips out of the edge of my re-handled Spyderco Junction after my post-lockdown trip. The PSF27 in that knife is a variant of D2 tool steel. The edge was snagging a little on paper although I couldn’t by eye see the reason for this. I have a cheapie fixed magnification 100x microscope however - courtesy of AliExpress for $10 - that despite the price was sufficient to quickly identify the cause.

Having decided to take these chips out as part of a re-sharpen, I thought I’d also take a few photographs of the surface of the edge as I went along, linking them to the size of the abrasive being used, and then post them here for forum members who are interested in this sort of thing. The abrasives were all diamond water stones from Venev that I reviewed here a few months back.

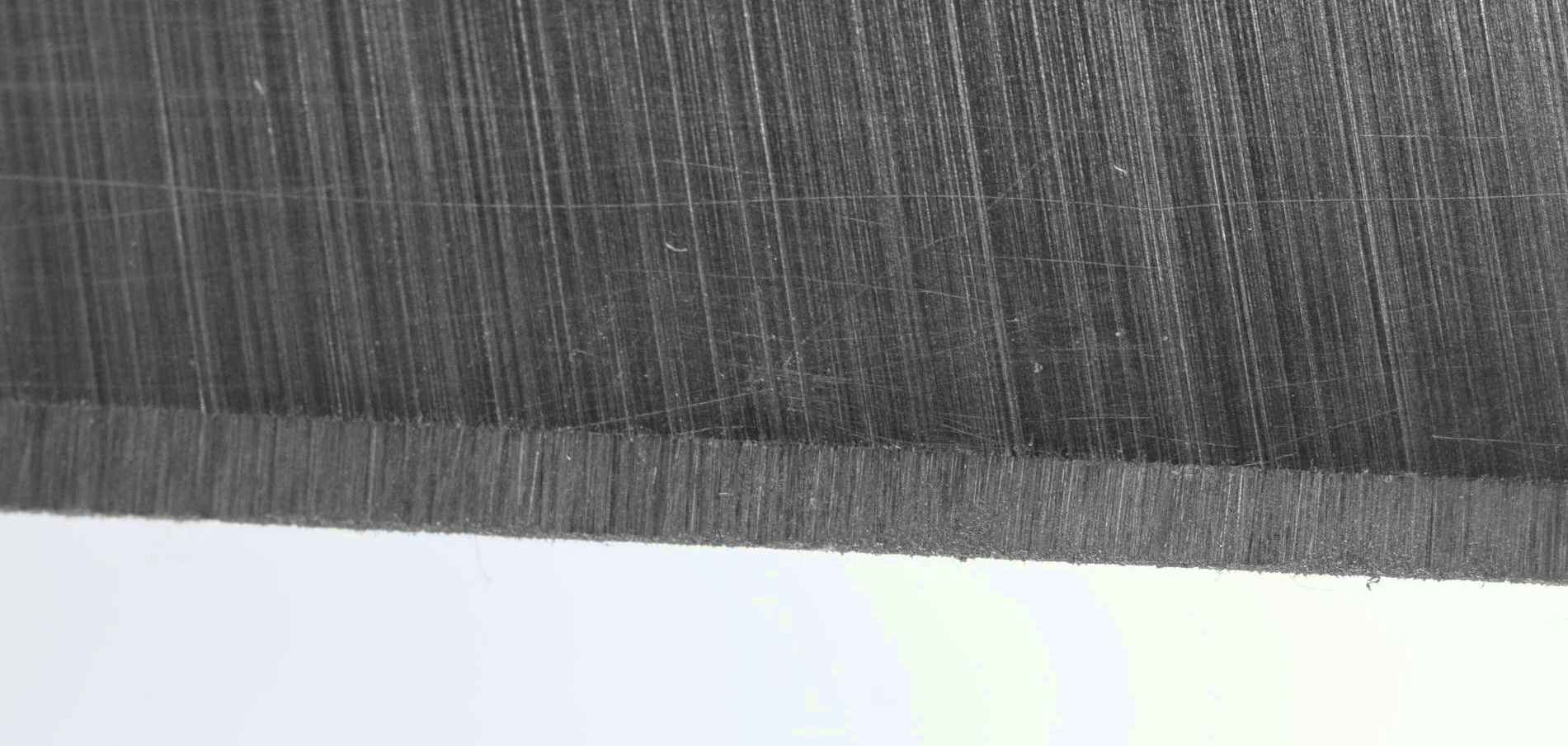

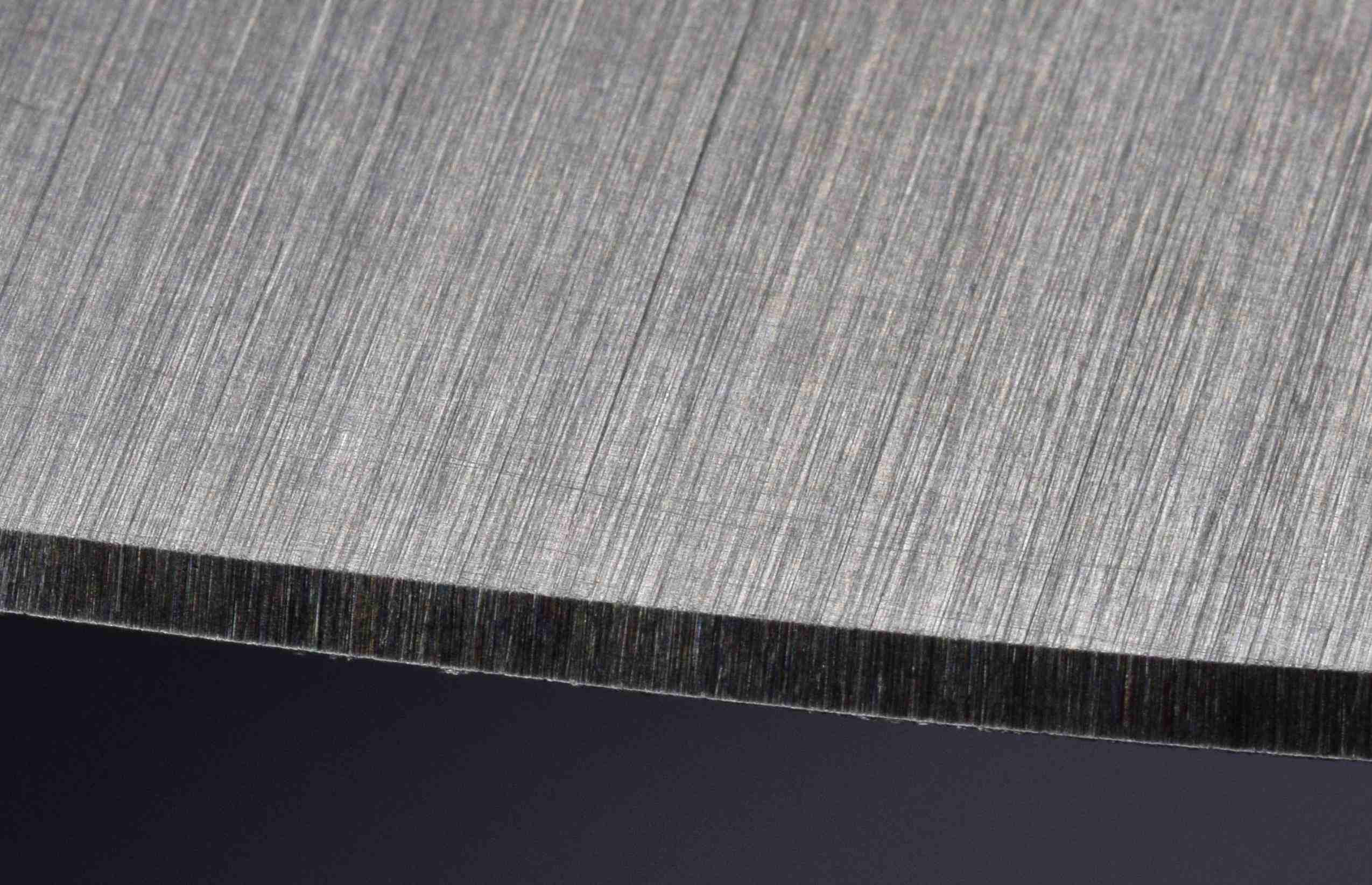

For starters, this is the front end of the blade being sharpened. The blade is a full flat grind, about 0.55mm behind the edge, and overall 25mm deep. I apply a 15° edge, so the bevel according to my calculations should average a little over 1mm in width. These dimensions will give a sense of scale to some of the photos. The close-up images of the scratch patterns show about 0.7mm of the bevel.

Below is the edge following removal of the chipping with an 80-100 micron stone.

I included this so that the edge finish may be compared to the brushed finish on the primary grind.

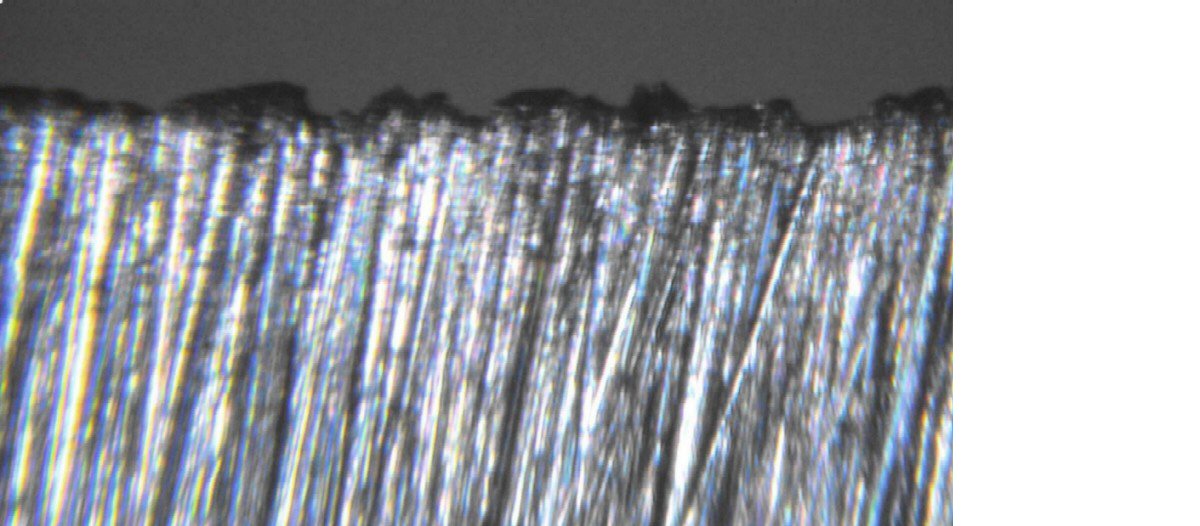

This is a view through the microscope of the apex with the light source directed along the edge to maximise surface contrast. This is on the side where I had just finished with the 80-100µm stone. The dark edges are the back of the burr. This unevenness is not easily seen by the unaided eye – at least not by my eyes.

By flipping the blade over to the reverse side, the burr can be best seen by getting it to catch the light with the angle just right. It can be more easily felt on a fingernail than seen.

Here is a look at part of that burr from the 80-100µm stone on the reverse side through the microscope.

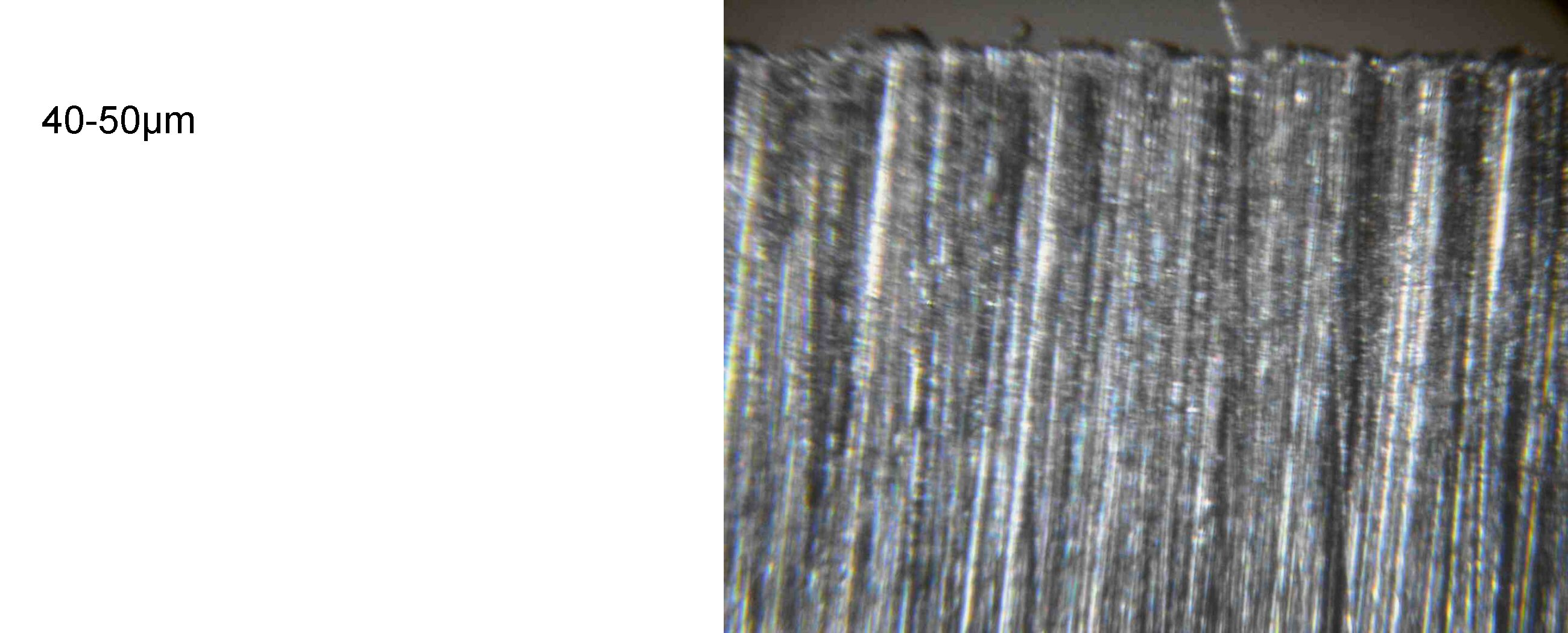

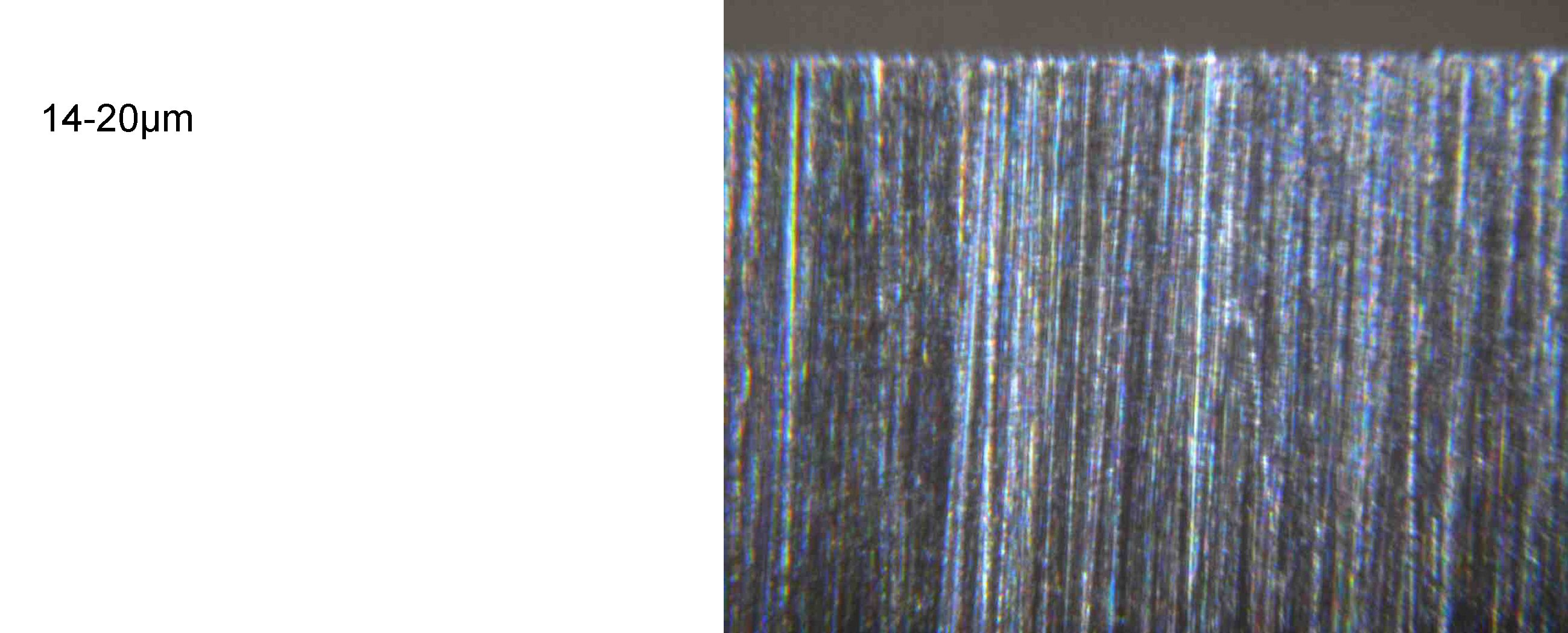

I then took the edge through the 40-50µm and 14-20µm stones. 14-20µm is where something approaching a reflection begins to be seen off the edge.

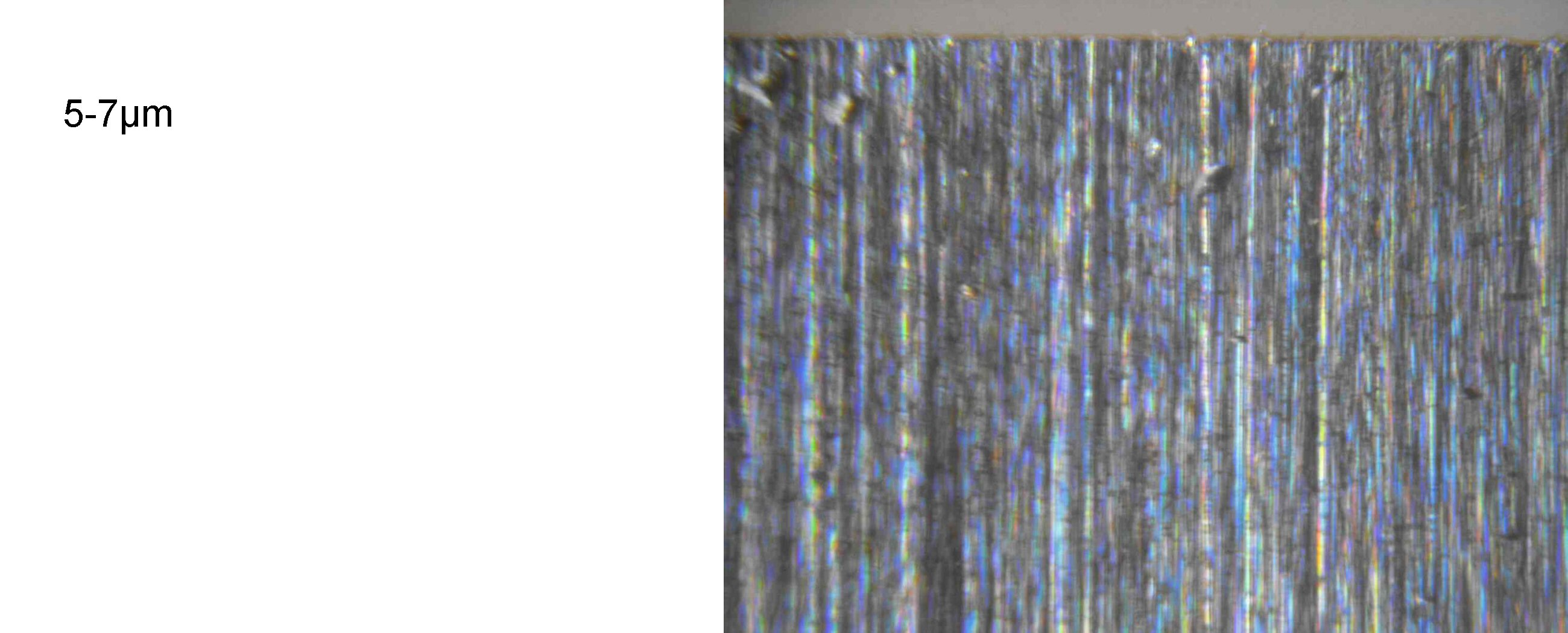

The 5-7µm abrasive is where the magic begins, as below…

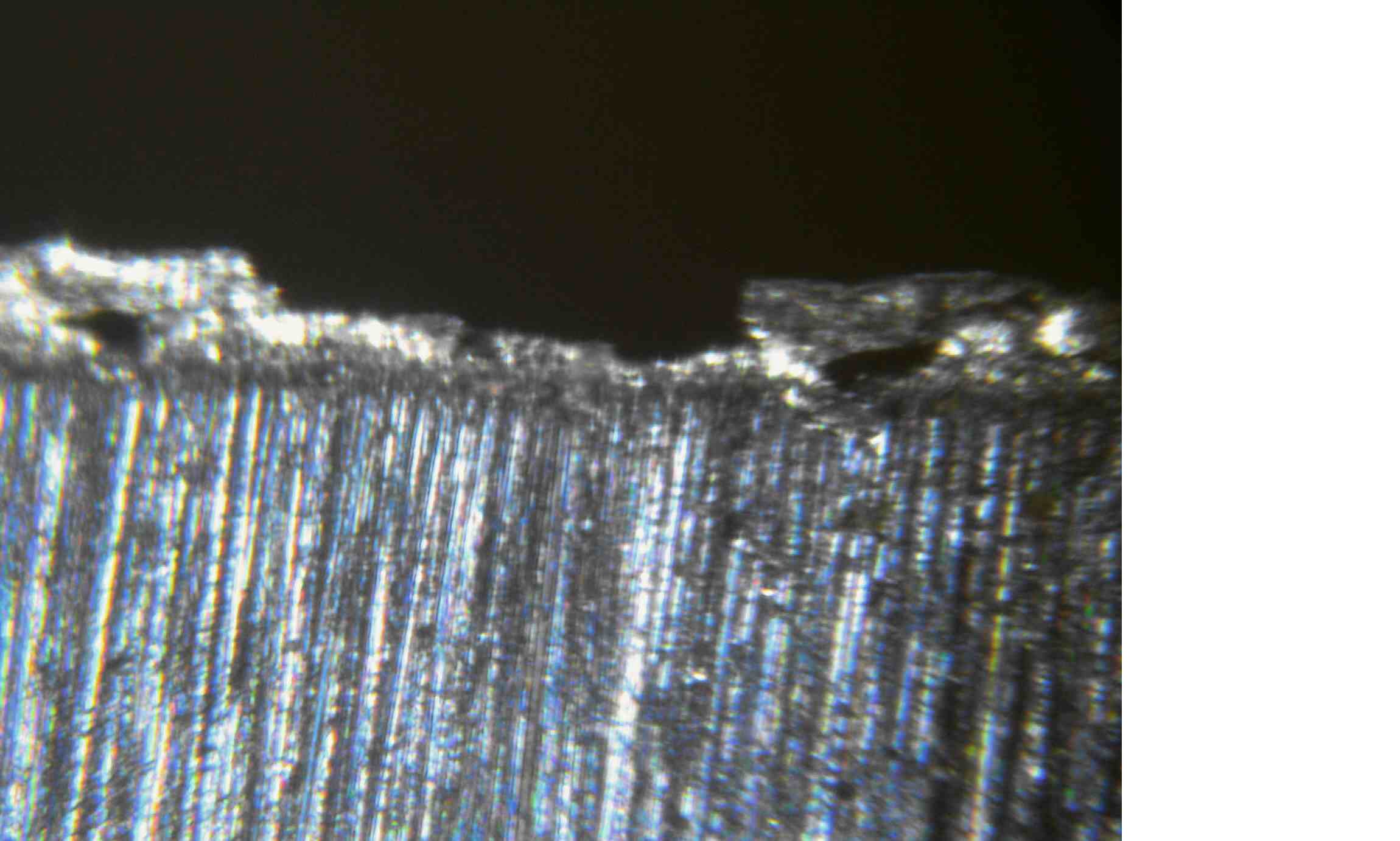

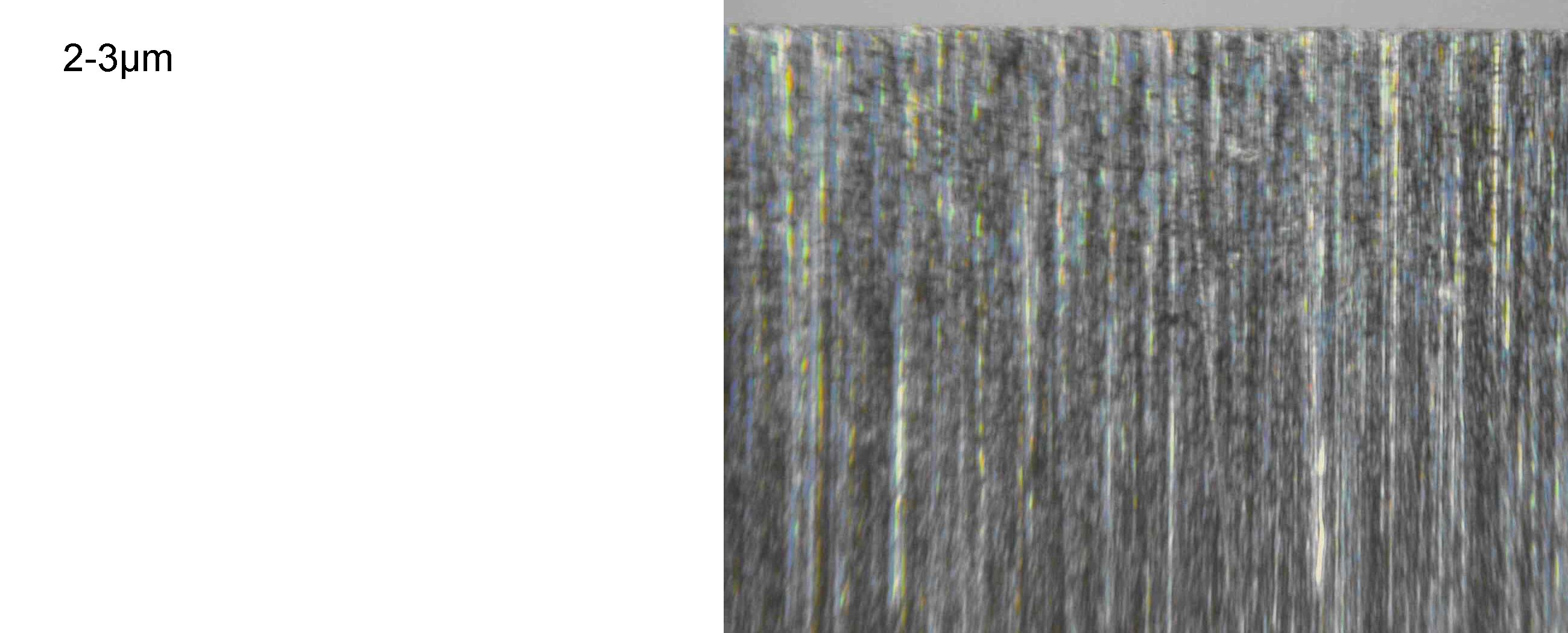

I refined the edge further using the 2-3µm stone. I might do a follow-up post showing any change to the finish from then using a 1 micron diamond stone followed by 1 and ¼ micron diamond emulsion on strops, but for now here are additional scratch patterns under the microscope for the different abrasive sizes, as before with the edge illumination at right-angles to the pattern unless otherwise mentioned.

Even with the finer finishes, there is nothing mirror-like to the surface when it is viewed with magnification. That said, the illumination angle used makes a big difference to how the surface appeared. Below is when the same 2-3µm finish is viewed with the light shining straight onto the edge at right-angles rather than shone along the blade. Little sign of the scratch pattern shows up at all. Even with the edge being shaving sharp, the imperfections right at the apex may now be clearly seen. The horizontal lines I think have been added when wiping the edge clean, probably from the odd loose piece of abrasive picked up on the cloth. Diamond is still merciless on steel with a HRC hardness in the low sixties!

Observations or opinion? I’ve found a microscope to be very helpful for seeing what the effect has been of each abrasive. While an expert may be able to hand sharpen, and do this by feel, I need a guided system, and even with a guided system there are pitfalls that high magnification can identify that would otherwise go unnoticed by me.

I have mentioned this in other posts, but I think it is worth noting again: it is essential in a guided system that every abrasive contacts the knife apex at EXACTLY the same angle as every other. Each successively finer stone is less able to remove sufficient material to correct for an error in applied angle than the previous. Any system where the knife is repeatedly flipped to progress through the grits must restore the blade to an absolutely identical position following each rotation. Even in systems like the Wicked Edge where the blade is held fixed through the entire process; any slop or flexing in the slide rods, or the different grades of stone being of an uneven thickness or wear, will change the angle of application. It is surprising how often I thought I had worked the edge fully with a particular stone only to see under the microscope areas where the scratch pattern of the previous abrasive remained untouched because of a slight angle difference. I would never see this by eye.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 36

-

22-05-2020, 11:22 AM #1

Sharpening a D2 knife blade: some photos, observations, and opinions

-

-

22-05-2020, 11:48 AM #2Member

- Join Date

- Mar 2012

- Location

- Christchurch

- Posts

- 1,497

Very interesting post. I had no idea before of the changes with different grades of finish. Excellent photos.

-

22-05-2020, 01:33 PM #3

Very interesting. The view through the microscope looks remarkably good, mind sharing which aliexpress offering it was?

-

22-05-2020, 02:02 PM #4Banned

- Join Date

- Mar 2015

- Location

- North Canterbury

- Posts

- 5,462

To get rid of the Burr I always run the knife across a piece of hardwood between stoning and after the first steeling

-

22-05-2020, 05:46 PM #5

https://www.aliexpress.com/item/4001...archweb201603_

A product search for "Loupe" in combination with "100x" should bring up quite a few vendors of what appears to be the same item.

-

22-05-2020, 06:40 PM #6Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,451

I have never had much time for D2. Difficult to sharpen and chippy. But plenty of people seem to like it.

CPMD2 however is quite a different steel and a very good one. But not very common - mainly because of the confusion between the 2 steels and the bad wraps ordinary D2 gets.

-

22-05-2020, 07:13 PM #7

@Tahr. PSF27.

-

22-05-2020, 07:42 PM #8Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,451

-

22-05-2020, 09:27 PM #9Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,451

Sorry, CTS XHP

-

23-05-2020, 03:17 PM #10Member

- Join Date

- Mar 2014

- Location

- Tauranga

- Posts

- 3,020

D2 can make a fine knife. It has relatively large carbides and as such suit a toothier edge. For this reason they suit a hunting knife well, but less so a razor or fine work kitchen knife. The big carbides mean they aren't super tough, but do hold an edge really well. At higher hardness edge retention isn't far behind 3v or s30v.

There are a few very well regarded makers using D2 to make excellent knives. Dozier is probably the most famous of them. I have a cbk in D2, is has one of the "stickiest" edges I've used. Fantastic on game.

The steel can be batchy reportably, CPMD2 was created to try get a finer carbide solution.

If you are finding it chippy puffin try lowering the edge geometry a couple of degrees, maybe 17 ish. The lack of refined edge under the fine stones will likely be due to the large carbides washing out right at the edge. Personally I would stop at the second finest stone. I only take my D2 to 1200.

-

23-05-2020, 03:49 PM #11Member

- Join Date

- Jul 2012

- Location

- Invervegas

- Posts

- 5,647

Interesting post @Nick-D. I agree whole-heartly with your thoughts.

I have a 40 year old custom by Robert Uddstrom that has been my everyday sheath knife for that entire period - I don't ever recall using another fixed blade knife outside for more than a few minutes. Has done a fair amount of game, and countless muttons, and many cattlebeasts. As I recall it was one of the first D2 knives available in NZ.

The edge on this knife has never chipped (I am careful to only risk engaging bone with the heel of the blade - eg knuckling sheep's legs). For the first 10-15 years I owned it we "duelled" between me and it to get it really sharp. With the advent of diamond stones and a carbide blade shaper I've never looked back - it holds an edge like no other (and I've tried a lot of steels in folders, admittedly I favour softer steels in these).

@viper is making me a new small knife in D2, it will be interesting to compare.

-

23-05-2020, 04:44 PM #12Member

- Join Date

- Mar 2014

- Location

- Tauranga

- Posts

- 3,020

-

03-06-2020, 06:40 PM #13Member

- Join Date

- Aug 2014

- Location

- Auckland

- Posts

- 719

D2 requires really good heat treatment, if you cool to slowly it won’t be happy.

-

03-06-2020, 07:40 PM #14Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,451

Large carbides = chippy.

Yes, Dozier has mastered D2, but look what you have to pay.

D2 might be OK when its viewed in isolation, but when compared to many alternatives at a similar price its pretty damn shit really.

-

03-06-2020, 09:41 PM #15Member

- Join Date

- Feb 2013

- Location

- Mangakino

- Posts

- 1,855

I am finding this discussion interesting.

My experience of using "good" (bit dearer) knives is limited.

I have been able to sharpen and keep knives sharp though.

Have used heaps of sheath knives over the years predominately doing sheep.

Did try Victorinox skinners but found they chipped and broke 1 or 2 sitting on them getting back on the tractor.

No idea what steel they were they were "stainless" the big new thing.

I used to be reasonably good doing sheep a mate and I could do 20 lambs in an hour between us without to much effort.

Not skiting heaps faster better than me,have a brother who is stronger faster just establishing a "benchmark of experience".

Getting on a bit now but did 8 hoggets last weekend with helpers/watchers.

Used my Jack knife I got of Nga which is D2 steel reading back on posts.

We shot them I cut all 8 throats to bleed them and probably did 5-6 in total with assistance for the balance.

I have found this knife to be pretty good using it with no steeling or anything.

Still as good at the end as the start,so find the previous comments on D2 steel interesting.

But as stated before have done enough and know enough to look after my knife when using them.

Similar Threads

-

Knife Sharpening

By Paua Pete in forum HuntingReplies: 7Last Post: 11-01-2020, 09:36 PM -

EXCHANGE A BLADE KNIFE

By bigbear in forum Gear and EquipmentReplies: 9Last Post: 16-03-2019, 05:09 PM -

making a knife and a sheath, part 5 - attaching the handle to the blade

By Shelley in forum Gear and EquipmentReplies: 2Last Post: 18-07-2015, 08:23 PM -

Old school replacement blade knife

By ChrisF in forum Gear and EquipmentReplies: 2Last Post: 17-06-2015, 11:27 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

41Likes

41Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks