Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1,126 to 1,140 of 2348

Thread: Show me your knives

Hybrid View

-

29-01-2019, 12:34 PM #1Member

- Join Date

- Mar 2014

- Location

- Tauranga

- Posts

- 3,019

-

29-01-2019, 12:52 PM #2

-

09-02-2019, 08:09 PM #3

@Nick-D and @dannyb those spikes are for intimidation factor.

Na seriously they are anchor points, the lanyard tab on these is about 4mm thick and tough like hell, those spikes are 10mm thick and mount onto a hand guard thats also thick as hell. There is a pic somewhere of a navy seal with one on his hip, must have been a gluten for punishment as they are heavy like a meat cleaver.

P.s. I am one tough son of a bitch now that I have this knife, dont fuck with me!Use enough gun

-

10-02-2019, 08:47 AM #4

-

10-02-2019, 08:53 AM #5Member

- Join Date

- Feb 2016

- Location

- Stewart island / canterbury

- Posts

- 9,193

-

30-01-2019, 11:53 PM #6

So I found this bloke selling his knives at a night market here in Punta Del Este (Uruguay)

You can check out his website by searching Willy Knives Uruguay.

This is a "Trapper B" made with N560 steel polished finish and the handle is Madera Itín which is a south american hardwood. Absolutely beautiful knives

The makers mark ( Willy R.O.U ) stands for Republica Oriental de Uruguay, which is the full and proper name for the country. He has a few others hes selling at the moment and I would buy them all if I didnt need a mortgage to fund it!

Flappy Disc Customs Bespoke Hunting Rifles

Flappy Disc Customs Bespoke Hunting Rifles

-

31-01-2019, 12:01 AM #7

This is another of his. The model is "Practicó " also in N560 with Chital/Axis Deer antler for the scales. He also has one of these with a hardwood scales which is also very nice.

USD$300 if anyone is feeling spendy and wants something unique Flappy Disc Customs Bespoke Hunting Rifles

Flappy Disc Customs Bespoke Hunting Rifles

-

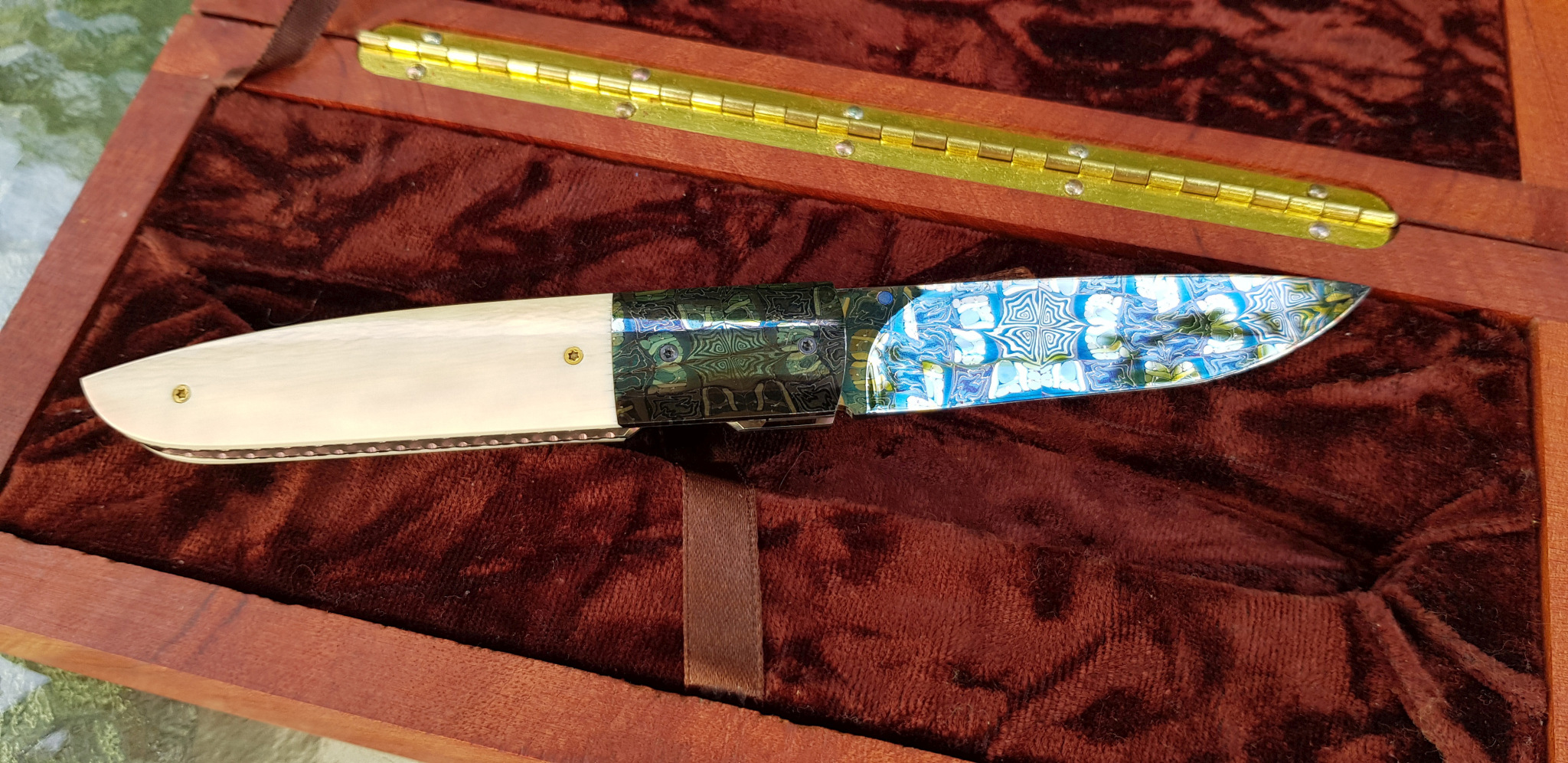

25-02-2019, 05:50 PM #8

Just got this one in

Regards

Regards

Terry

https://www.knives4africa.co.nz/

Custom knife dealer

Authorised Nitecore Torch Retailer

NZ Distributor of Nano-Oil

-

28-02-2019, 11:08 PM #9Member

- Join Date

- Feb 2019

- Location

- Christchurch

- Posts

- 681

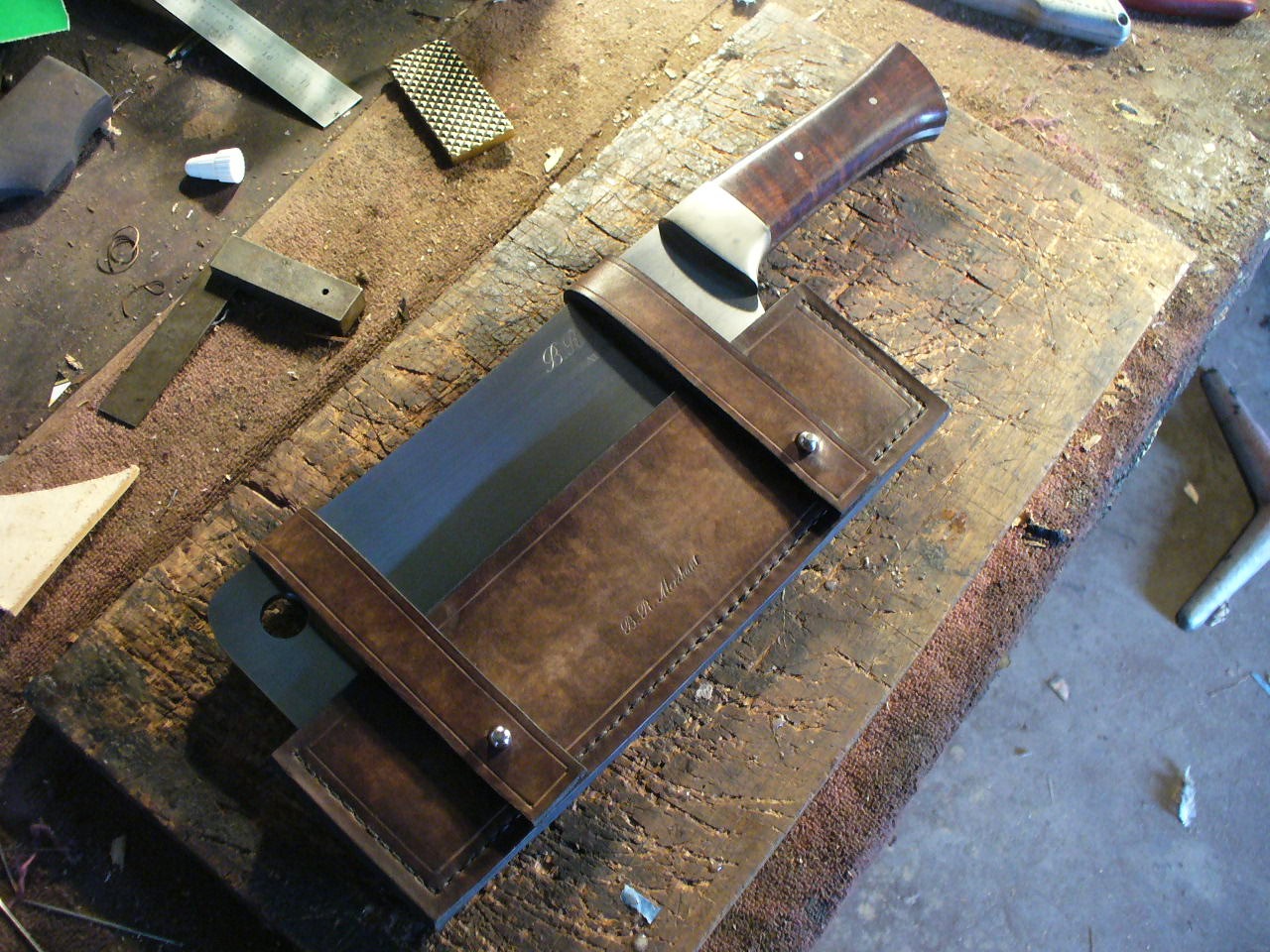

I’m new to NZH&S but thought I would share a couple of pics. Sadly made by my favourite Australian knife maker who’s no longer with us. Makers name engraved by hand ( no machine engraving). In D2

-

28-02-2019, 11:13 PM #10Member

- Join Date

- Feb 2019

- Location

- Christchurch

- Posts

- 681

And another by same maker. This a larger camp knife with crocodile scabbard. D2 steel. Tapered tang. Plain but beautifully crafted. Gidgee handle and titanium bolster.

Last edited by Southcity; 28-02-2019 at 11:21 PM.

-

05-03-2019, 09:27 PM #11Member

- Join Date

- Feb 2019

- Location

- Christchurch

- Posts

- 681

Here's a few more from my collection. Better photo of the Camp knife and matching Cleaver (both D2 with Titanium bolsters), small handy knife with Whale Tooth Ivory scales, and the knife I showed a photo of above I had engraved. All engraving is done with hand chisel.

-

06-05-2019, 10:34 PM #12Member

- Join Date

- Apr 2017

- Location

- Marlborough - Pelorus Sound

- Posts

- 5,459

-

09-03-2019, 08:24 AM #13

After grinding up the little rabbit knife in the top of the picture below, I was impressed by the comfort of the 3/4 length buffalo horn handle and the finger scallop. Works extremely well in a range of grips maximising the versatility of the blade. So, I decided to have a go at making a compact flaying and boning knife to match.

The two new blades are O1 tool steel. Now this steel is a bit more complex in its heat treat requirements over the 1075/1084 type plan carbon I have been playing with so far, but I have just purchased a heat treat kiln so was looking to experiment!

so was looking to experiment!

Following internet based recommendations the blades were normalised three times with a quench on the last cycle, then hardened and tempered. Unfortunately, the anti-carburizing past that I used failed during the normalising heat cycles, and as a result I did lose a bit of carbon from the steel in the process. The heat treat should have yielded 60-61 HRC but a test by the local metallurgy lab have 58HRC. Still up there with most commercially produced blades, and it did make the blades easier to sharpen in comparison with the rabbit knife which I suspect is in the low 60's based on how long it took to get an edge on my water stones.

Blade surfaces was left as heat treated.

Then the next fun part was making my first ever kydex sheaths.

Kydex is wickedly expensive by my standards, so I hunted for some alternatives. Found a company selling 6'x4' sheets of ABS for around $70 so ordered that instead.

Watched a few youtube clips and then had a go.

Due to the slim, compact shape of the knives, I decided to try for a double stack ……..

All of this has been in an effort to keep my learning one step ahead of the boys (and a couple of their dad's) that come around on a Thursday to learn to build stuff in the shed.

-

09-03-2019, 04:11 PM #14Member

- Join Date

- Mar 2014

- Location

- Tauranga

- Posts

- 3,019

-

06-05-2019, 10:23 PM #15Member

- Join Date

- Apr 2019

- Location

- Myanmar ex Auckland

- Posts

- 8

After lurking on the forum for a few years I finally joined. I must say that I hold this forum responsible for starting me down the knife/ blade rabbit hole. Which all started with a thread on Bahcos...

Now rather than make a new thread, I thought I should ask this knife question here.

Has anyone had any good/bad experience with the Canadian belt knife pattern? It looks like it would be a knife that's not too big not to small.

For example the Grohmann #1 / Bird n Trout/ or Knives of Alaska Yukon?

The steel is not the best in those examples, it was more a question on the pattern than a particular knife.

Cheers

Similar Threads

-

Zedteq Knives

By Philipo in forum NZHS Bulk Buying SectionReplies: 33Last Post: 29-04-2013, 08:24 PM -

custom knives...cost etc

By moonhunt in forum Gear and EquipmentReplies: 28Last Post: 25-02-2013, 10:47 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

4893Likes

4893Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks