A set of Venev 150mm x 25mm x 11mm diamond water stones arrived recently from Gritomatic for keeping the knife edges here in good nick. These are each double-sided, and as there are three pieces in the set, I ended up with six different grades of abrasive ranging from F80 through to F1200. Each stone is clearly labelled on their sides with the FEPA F grit size and the matching abrasive diameter in microns

There is good product information here:

https://www.gritomatic.com/products/...amond-full-set

These can be purchased through Amazon or directly from Gritomatic, and were under NZ$150 delivered for the set.

I’ve been disappointed in the past with diamond sharpeners because of what seemed to be the quick loss of abrasive from the tools’ surfaces. These stones promise to be different in having the diamonds embedded within a resin layer rather than coated on the surface as in the traditional DMT or Eze-Lap products. Bonded diamond stones like the Venev can apparently be repeatedly rejuvenated by refacing the surface using loose silicon carbide on glass to expose fresh diamond.

There was plenty of abrasive clearly visible within the surface of the courser stone – above: the faces of a few of the diamonds can be seen catching the light along with the texture of the bonding substrate.

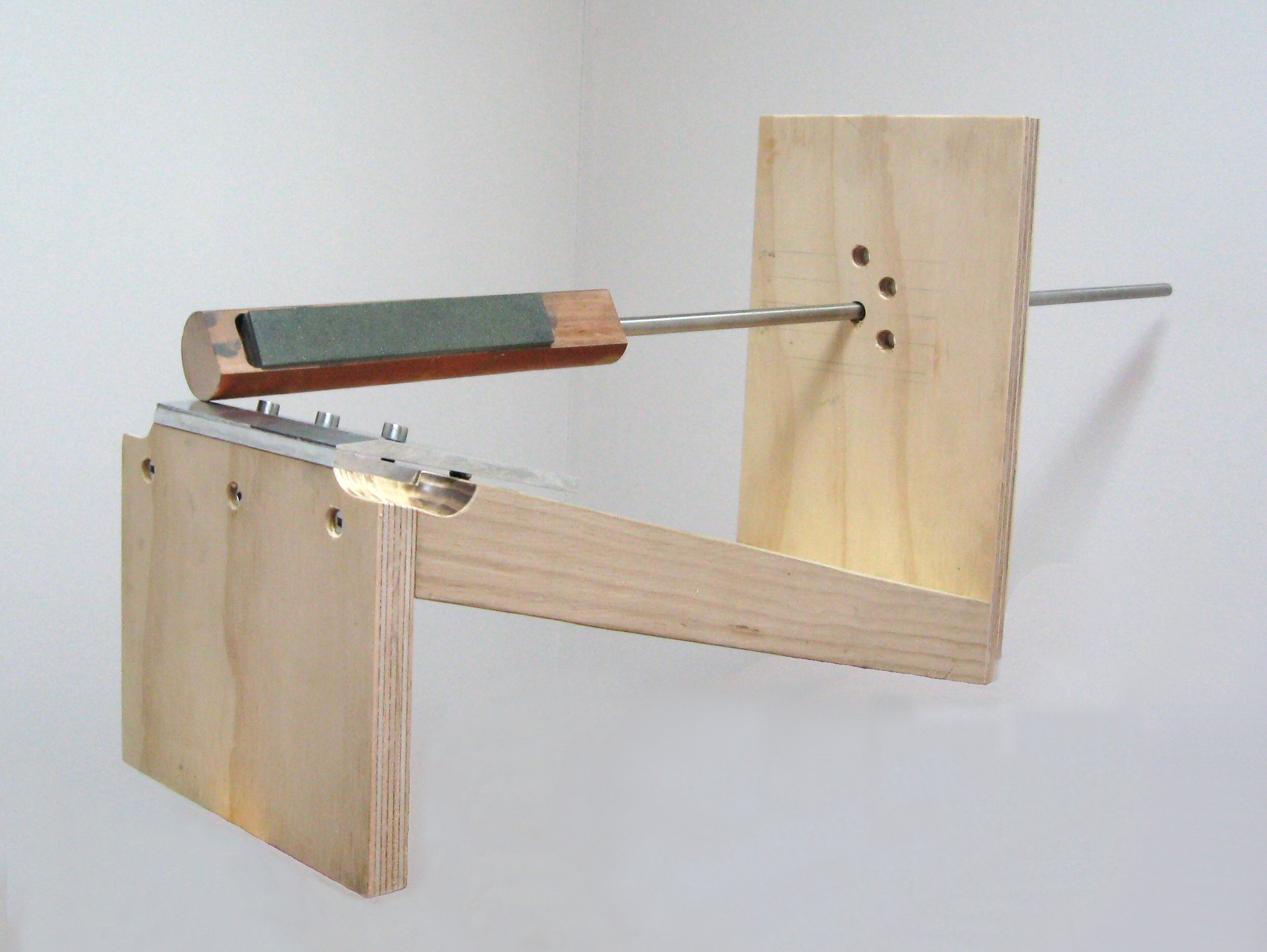

The advertising material says that this 150mm x 25mm size of stone is intended for use in a sharpening jig (that Gritomatic also stock) where they are clamped from the ends, and unlike the heavier 200mm x 75mm stones, this smaller size does mean that a way of holding them steady for use will be needed. With abrasive on both sides this can’t be done by gluing them down. One possibility would be using a router to slot a fixed timber board, and then the stones could be dropped in either way up. Hand sharpening is not a skill I intend to learn so I went the other way and decided I would keep my knives stationary and fit the stones to a homemade jig of the same basic design as the commercial models. The sliding handle was made from beech dowel recovered from a broken sun umbrella.

I made a clamp for the blades from some aluminium plate held together with hex cap screws and then set this up at an angle to the horizontal on a 45mm base with ply ends. The holes at the rear are measured out for 15°, 17°, 19°, and 21° bevel angles.

After having a play by putting a mirror finish on my old Svord Utility Drop-Point at 17 degrees a side, I set to re-working the edge profile on a Cold Steel Ultimate Hunter folder in XHP. These apparently all come with an asymmetrical bevel and the one I had was no different. However the 80-grit Venev soon removed this and established 15 degrees on each side.

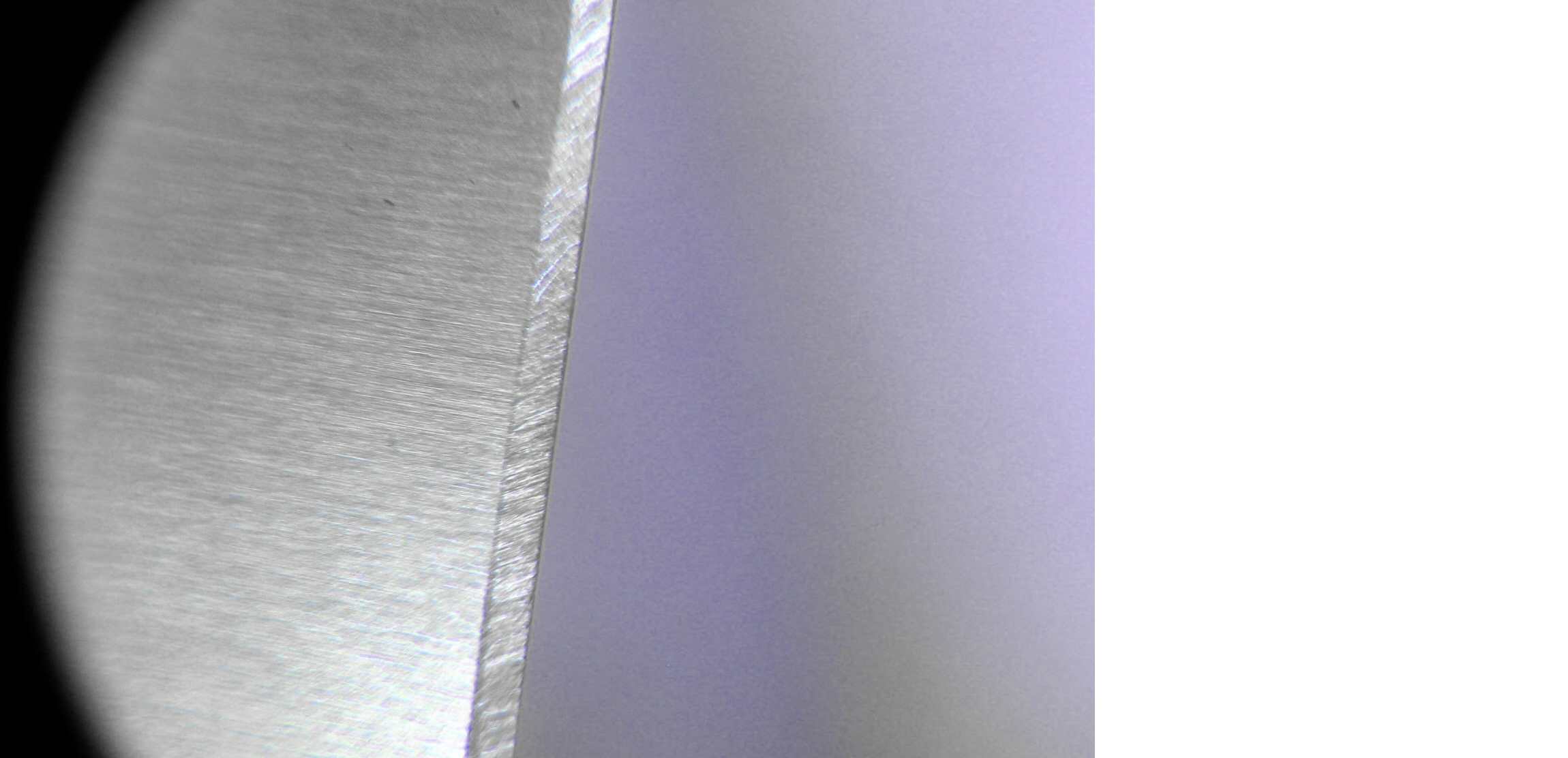

On the left above is the blade’s brushed-satin finish. The aggressiveness of the 80-grit stone can be seen in the new edge being formed. The slight black line down the RHS on the cutting edge is the last remnant of the original 20° bevel.

I then worked my way through the remaining 5 grades of stone until I had a I thought was a pretty slick looking finish. Not hair-whittling sharp, but shaving sharp, and plenty good enough for doing a deer.

One additional item that would be useful is a Nagura dressing stone or Sabitoru rust eraser for removing the load-up on the water stones – particularly from the finer grit surfaces.

Conclusion

This Venev stone set seems to be an excellent choice for someone like myself who only has a handful of knives, particularly if any of the blades have a high content of hard carbides where diamond abrasive may be preferred. The range of grits covers re-profiling through to developing a reasonable finish.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 8 of 8

-

13-07-2019, 01:19 PM #1

Venev 150mm x 25mm Diamond Water Stones - Review

-

-

13-07-2019, 05:43 PM #2Member

- Join Date

- Mar 2014

- Location

- Tauranga

- Posts

- 3,019

That's a pretty good polish for 1200mesh. Would be surprised if that wasn't quite a bit finer than advertised. No need for 80 grit unless the edge is basically non existant. Do they cut fast?

Strop to 10k after that stone and it will whittle

-

13-07-2019, 05:51 PM #3

Thanks Puffin, now I have started knife making I realize knife sharpening is a whole subject in itself . Good review and thanks for taking the time to do it.

-

13-07-2019, 07:03 PM #4

Online reports do say these stones are less aggressive than the (supposedly) equivalent DMT plates.

The 80-grit Venev though was still fine for the re-profiling I needed to apply so I'm pleased it is included and available for tasks like removing chips and changing bevel angles.

-

13-07-2019, 07:11 PM #5Member

- Join Date

- May 2018

- Location

- Porirua

- Posts

- 1,342

Great review @Puffin I’ll have a go at a similar edge by hand but I suspect I’ll be copying your jig and buying some Venev for myself.

Remember the 7 “P”s; Pryor Preparation Prevents Piss Poor Performance.

-

05-08-2019, 12:52 AM #6

This review discusses the larger 8" x 3¼" size, but these are the same combinations of surface abrasive (and colour) as found on the smaller 6" x 1" size.

https://www.youtube.com/watch?v=CpUP8lP6ilg

An earlier review on the smaller size.

https://www.youtube.com/watch?v=9GDlfhUSvTs

-

05-08-2019, 09:12 AM #7

Similar Threads

-

sharpening stones back in stock

By terryf in forum Knives 4 AfricaReplies: 14Last Post: 05-07-2019, 06:57 PM -

Victorinox Dealer/Sun Tiger stones

By terryf in forum Forum SponsorsReplies: 0Last Post: 31-01-2019, 08:38 PM -

Leder Tanning kits - Rain water or Tap water

By FletchNZ in forum TaxidermyReplies: 13Last Post: 19-06-2014, 03:20 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

6Likes

6Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks