I have a 10m cable on my Tm260. I need about 1.0m of this for the worlds smallest offshore sportsfishing boat, and I am mildly concerned having the remainder coiled up and cable tied to the transom is causing some undetectable loss of performance.

Some people say you can't shorten transducer cables for some vague reason. Others say it's fine. Airmar sell the Tm260 as a "mix n match" setup with various cables which would indicate that it's actually fine.

What's the real story, and is there any outfit that offers the service?

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 17

Thread: Shorten transducer cable

-

09-01-2023, 09:10 PM #1

Shorten transducer cable

-

-

09-01-2023, 09:18 PM #2

It can be shortened, cut it at the display plug end. Leave 1m tail so it makes it easy to connect to what ever length you want still attached to the transducer.

DO NOT CUT IT AT THE TRANSDUCER END ever!!

TM260 is very narrow beam width so I assuming you are fishing over 100mTrust the dog.........................................ALWAYS Trust the dog!!

-

09-01-2023, 09:20 PM #3

When I was kayak fishing, it was a common issue. Standard advice was never cut a transducer cable full stop. There's magic in those cables!

-

09-01-2023, 09:33 PM #4

-

09-01-2023, 09:45 PM #5

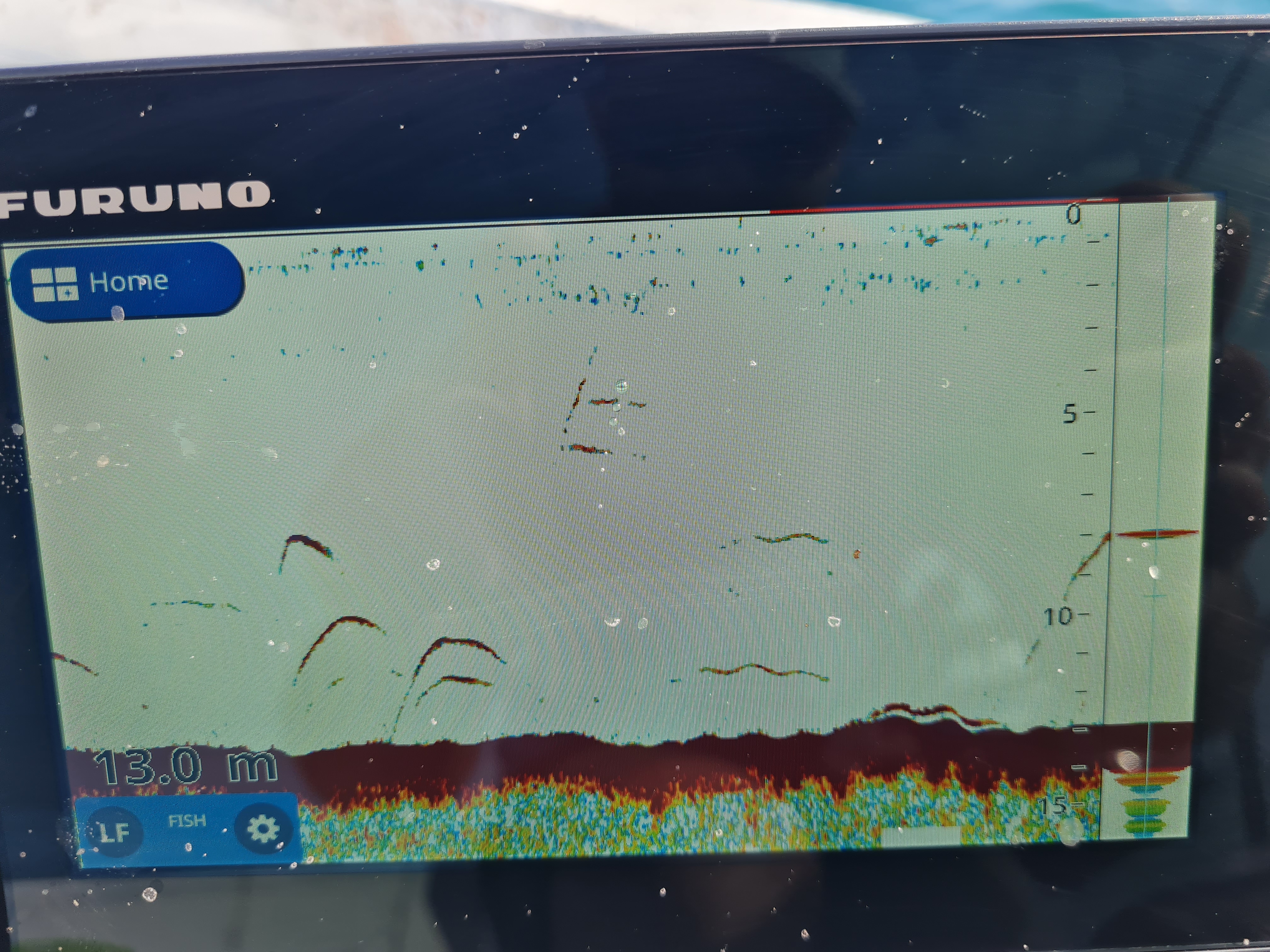

Resolution is OK in shallow on LF for what I'm doing, with the DB7

-

09-01-2023, 09:49 PM #6

At least its the right brand

Trust the dog.........................................ALWAYS Trust the dog!!

Trust the dog.........................................ALWAYS Trust the dog!!

-

09-01-2023, 10:46 PM #7Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 6,016

If you've never shortened one, I wouldn't be trying to learn on your own put it that way. They can be done, but some of the plugs don't come apart nicely and will need to be replaced. Also fiddly, and for some reason (possibly the quality of the solder we get in NZ) the reattached plugs seem to end up more prone to corrosion than the factory versions. My advice such as it's worth, is don't cut it but also don't coil the spare cable as that creates the potential for an attenuation or choke which can affect performance. What you can do which works is run the cable under the transom the full width of the stern to lose the extra amount, cable tying it right up out of the way and not overlapping the curve backs.

One of the reasons I say this, is that it's not unheard of to have a cable get damaged at the head end and in that case if you've shortened it you're potentially in the crap and either need to extend the cable (not ideal and prone to creating issues as the magic smoke transfer conduits get kinked) or go the expensive way and replace the transducer. The other possibility is you get the option of selling the transducer off at a later date when something newer and better takes your eye...

Although, with a 1m cable you shouldn't have any loss of power.

-

09-01-2023, 10:57 PM #8

I've got a worthless P66 to have a trial run at...

-

10-01-2023, 09:09 AM #9Member

- Join Date

- May 2016

- Location

- Blenheim

- Posts

- 1,206

I too was advised not to shorten cable. I flaked my excess back into the alloy ducting along gunwhale of the Stabi, thus keeping both ends intact. Sounder works fine.

-

10-01-2023, 02:47 PM #10

mikee knows what he is talking about...trust me

Forgotmaboltagain+1

Forgotmaboltagain+1

-

10-01-2023, 03:14 PM #11Member

- Join Date

- Jan 2013

- Location

- Home - mainland nz, actual - Auckland

- Posts

- 5,455

Cut, stagger joint (solder), individually glue heat shrink, make sure shielding is really well done, glue heat shrink over the whole joint space.

Gold standard - self amalgamating tape between individual wires before final heat shrink.Please excuse spelling, as finger speed is sometimes behind brain spped........ Or maybe the other wayy.....

-

10-01-2023, 10:39 PM #12Member

- Join Date

- May 2018

- Location

- wellington

- Posts

- 1,861

I've cut mine of, and wired it direct into a gsd26 xducer is a tm265lh, works fine. See fish on the bottom. At 200m with ease

-

11-01-2023, 06:24 PM #13Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 6,016

Well, not really. If you want it waterproof to immersion standard, solder and heatshrink each core, strength member it to minimise the chances of a yank failure and seal one end of a dual wall heatshrink that will cover the lot. Then either get thin silicone sealant or thin some down and pour it into the center of the joint, and seal the other end of the heat shrink. Once both ends are shrunk and sealed, work the center and make sure the sealant coats everything then shrink the center down as well. It's a bit more fluffing about, but I've had those joints survive down to 100m thereabouts for months.

-

11-01-2023, 06:46 PM #14

Good thread this I'm learning stuff !!

Trust the dog.........................................ALWAYS Trust the dog!!

-

11-01-2023, 08:49 PM #15Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 6,016

The other possible way is the 3M-type epoxy mold connections where you clip the mold onto the cable(s) and then pour the epoxy in which physically seals the joint inside a resin tomb. I don't like them for two reasons neither of which relates to the success of the joint - 1) they are very bulky which leads into 2) they are a bulky hard point which gives two flex points one at either end of the resin. I've had the cable fail at the join a couple of times...

Similar Threads

-

Transducer/sounder upgrade advice

By Hayden C in forum FishingReplies: 7Last Post: 14-06-2021, 11:29 AM -

Ok so you can shorten a 270 what about

By wayno in forum Firearms, Optics and AccessoriesReplies: 16Last Post: 06-03-2021, 11:38 PM -

What length to shorten a 7m08?

By Manu in forum Firearms, Optics and AccessoriesReplies: 17Last Post: 31-10-2016, 08:42 PM -

Shorten your .17 HMR ???

By Happy in forum Firearms, Optics and AccessoriesReplies: 44Last Post: 23-05-2014, 07:42 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

11Likes

11Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks