akaroa old mate old pale, I can see you are getting there, which is good but all the stress you are putting on your self I can help out. Just let me take it off your hands, think of it as stress relief , and as I have a .510" barrel I can put it to good use!!!,

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 30 of 44

Thread: 1885 rustoration

-

22-02-2020, 04:56 PM #16

-

-

22-02-2020, 05:48 PM #17Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,847

@homebrew.357 no stress at this end

I made two complete spring sets for 1885s copying my original low wall ones.

A mate friend and hardened and tempered them.

Both sets work perfectly

So now I can put the low wall back together and push on with re boring and cut rifling the #3 barrel I have

-

08-05-2022, 05:39 PM #18Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,847

This project came to the top of the heap recently and I have made a stock set

Added a Lyman globe front sight and tang peep rear sight

-

08-05-2022, 05:40 PM #19Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,847

-

08-05-2022, 05:46 PM #20Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,847

Then the real work began

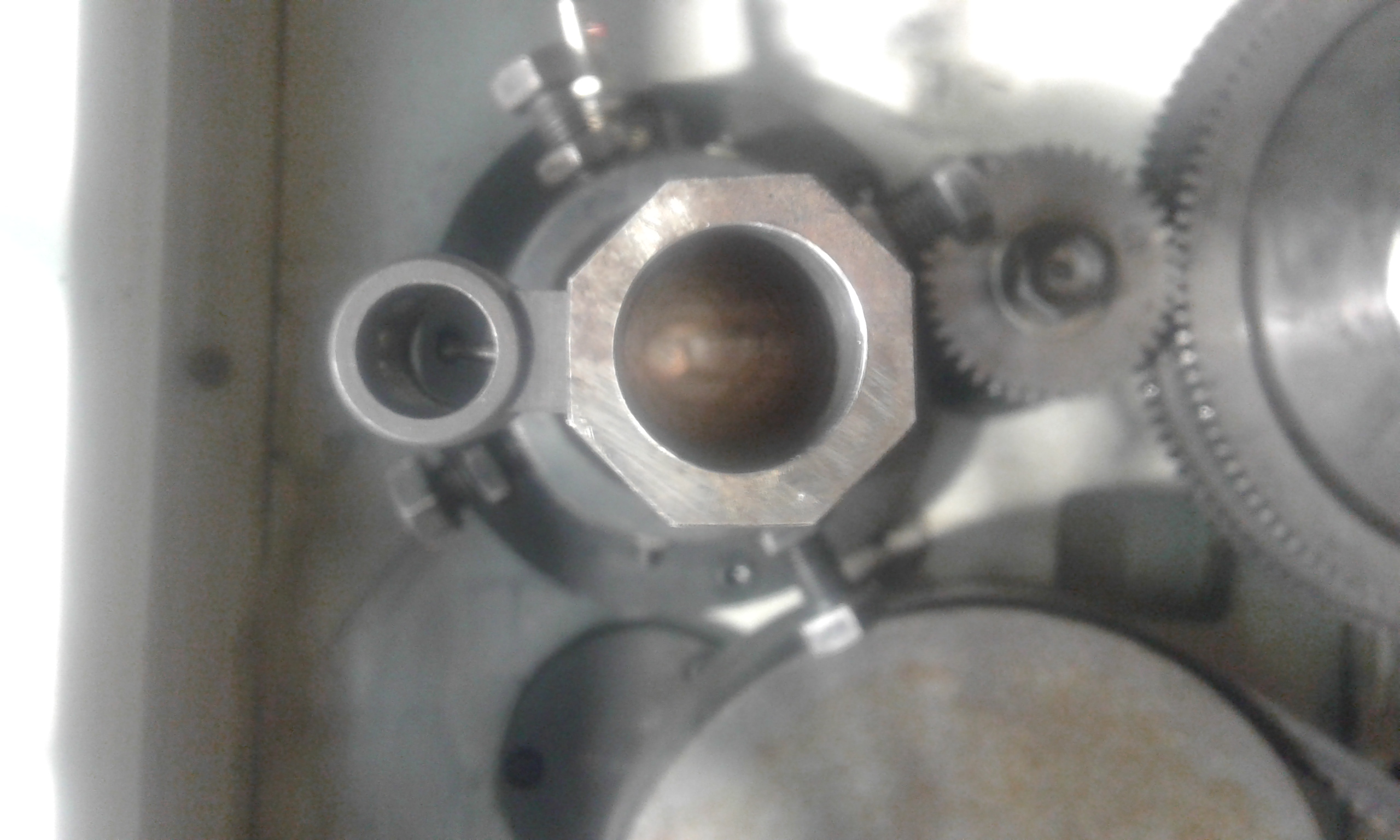

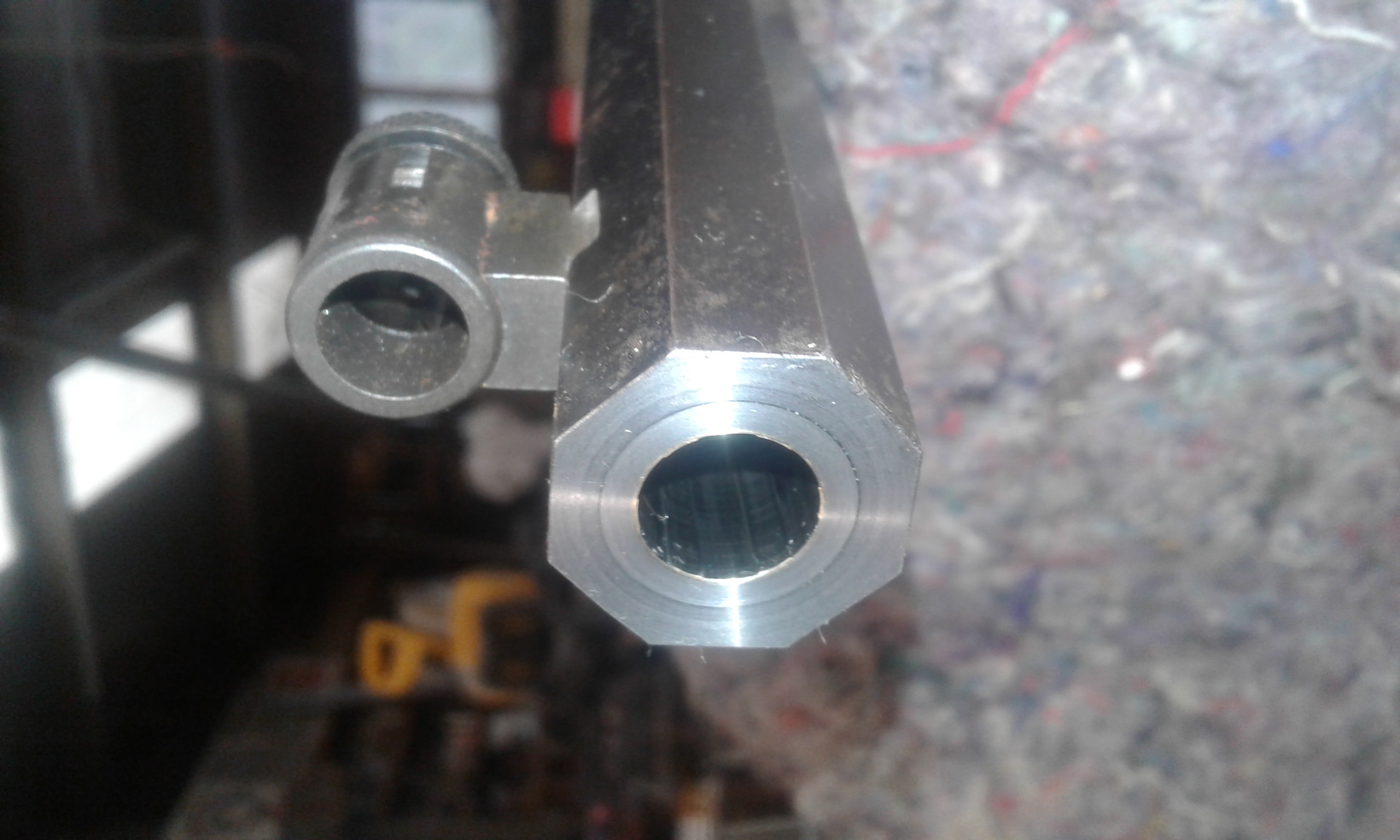

I made a bore guided drill on the Elliot tool and cutter grinder

And drilled out the entire barrel to 16mm

While it was in the lathe I took 3mm off the barrel shank end so I could deal with excessive head space

Then I turned down a 32" long stainless steel 45 cal Vulcan barrel to 16mm and left a 5mm flange at the breech end to deal with the head space

Then epoxy the liner in and force out excess epoxy at the breech in the shop press

-

08-05-2022, 05:54 PM #21Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,847

Set up barrel again in the lathe

Machine barrel shank and timing the octagonal flats and head space

Then team chamber 45-70

Turn it around and tidy up and lapp the muzzle

For the extractor and cut the slot for that

Then cut the extractor hook from .25 rimfire to the .45-70 rim

Fit a complete set of self made flat springs

And it fired a dummy round and even better the firing pin doesn't drag down the case when I open the action

So tomorrow a few proof rounds while the stock is still off being sanded and finished

And that's another rustoration maybe finished and it only took a few years

-

08-05-2022, 06:13 PM #22Member

- Join Date

- Jul 2021

- Location

- Whangarei

- Posts

- 503

Looking good, nicely done. A couple of questions how did you get on with the threads on the screws, single point cut or did you find something close. Also I was thinking of trying Vulcan for a 45 barrel (45 acp projects) are they any good?

Cheers

Darren

-

08-05-2022, 06:29 PM #23Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,847

The screws were made from scratch from silver steel rod and cut on the lathe

Actually better than the images give credit for

Vulcan barrels are great and I have used a few and have quite a few more on hand for future and current projects

Some of the barrels have been done for me within a week but Mr Vulcan is a close personal friend and gunsmithing mentor

-

08-05-2022, 06:44 PM #24Member

- Join Date

- Jul 2021

- Location

- Whangarei

- Posts

- 503

Great thanks for that, yep funny sometimes you get a great finish but looks awful in the photos….. cheers

-

08-05-2022, 09:37 PM #25Member

- Join Date

- Jul 2021

- Location

- Whangarei

- Posts

- 503

-

09-05-2022, 07:39 PM #26

Very nice, have any photos of the bore guided drill? I have a busted old barrel that could do with the same treatment.

-

09-05-2022, 08:09 PM #27

-

09-05-2022, 08:12 PM #28Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,847

-

09-05-2022, 08:33 PM #29Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,340

-

09-05-2022, 11:47 PM #30Member

- Join Date

- Jul 2021

- Location

- Whangarei

- Posts

- 503

Similar Threads

-

winchester 1885 stock to duplicate / take off

By akaroa1 in forum Projects and Home BuildsReplies: 0Last Post: 22-06-2018, 05:00 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

94Likes

94Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks