Ive been faffing around with a bunch of Lee Enfields of late, returning the best of them to full wood and parting out others etc. Its been a while since I did any work on these old girls and I wanted one in my safe that I could drag out for fun at the range from time to time.

I had a perfect donor for just that the metalwork is in great condition for a 1906 SMLE No1 Mk3 and it has a nice walnut stock but it was sporterized after ww2 like most others were.

The bore is one of the best sharpest, most shiny and least worn Ive seen in one of these with the exception of a bad pitting ring about 6" from the muzzle.

Ive always been a fan of carbines and short rifles so decided on a full wood carbine version that have become known as tankers or tank crew carbines.

While there were never any Enfields made like this from factory, there are many documented rifles like it cut down in the field for armoured vehicle crews, trench warfare and tunnel rats for whom the full length rifles were just to cumbersome.

For anyone interested in this bit of history you can read about it here:

https://www.milsurps.com/content.php...-Mk-III*-Rifle

I wanted to make it short but also refit the barrel band and end cap to make it look as much like the full length version as possible without messing up the over all scale of the fore wood. I decided a barrel length of 16.25" was the look I was after and would still keep enough velocity to shoot on the 300yrd range.

So after stripping the rifle and removing the barrel, I lopped off the end and spun it up in the lathe to recut the taper for the foresight.

I also recut the crown to look like the original one.

After realigning the fore sight and pinning it in place I touched up the blueing.

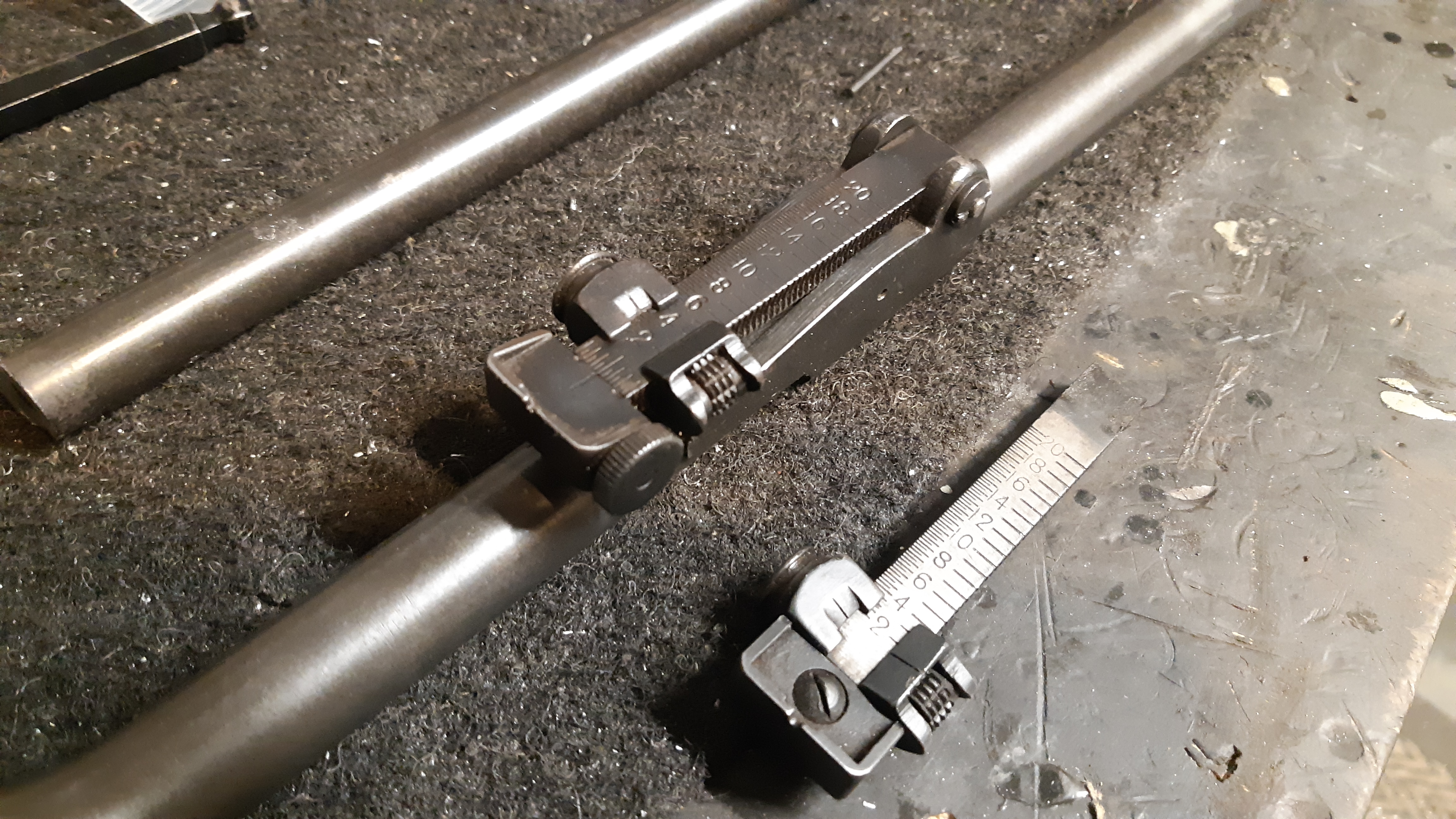

I also decided to replace the fixed rear sight with one of the adjustable windage sights for easier fine tuning.

On to the wood.

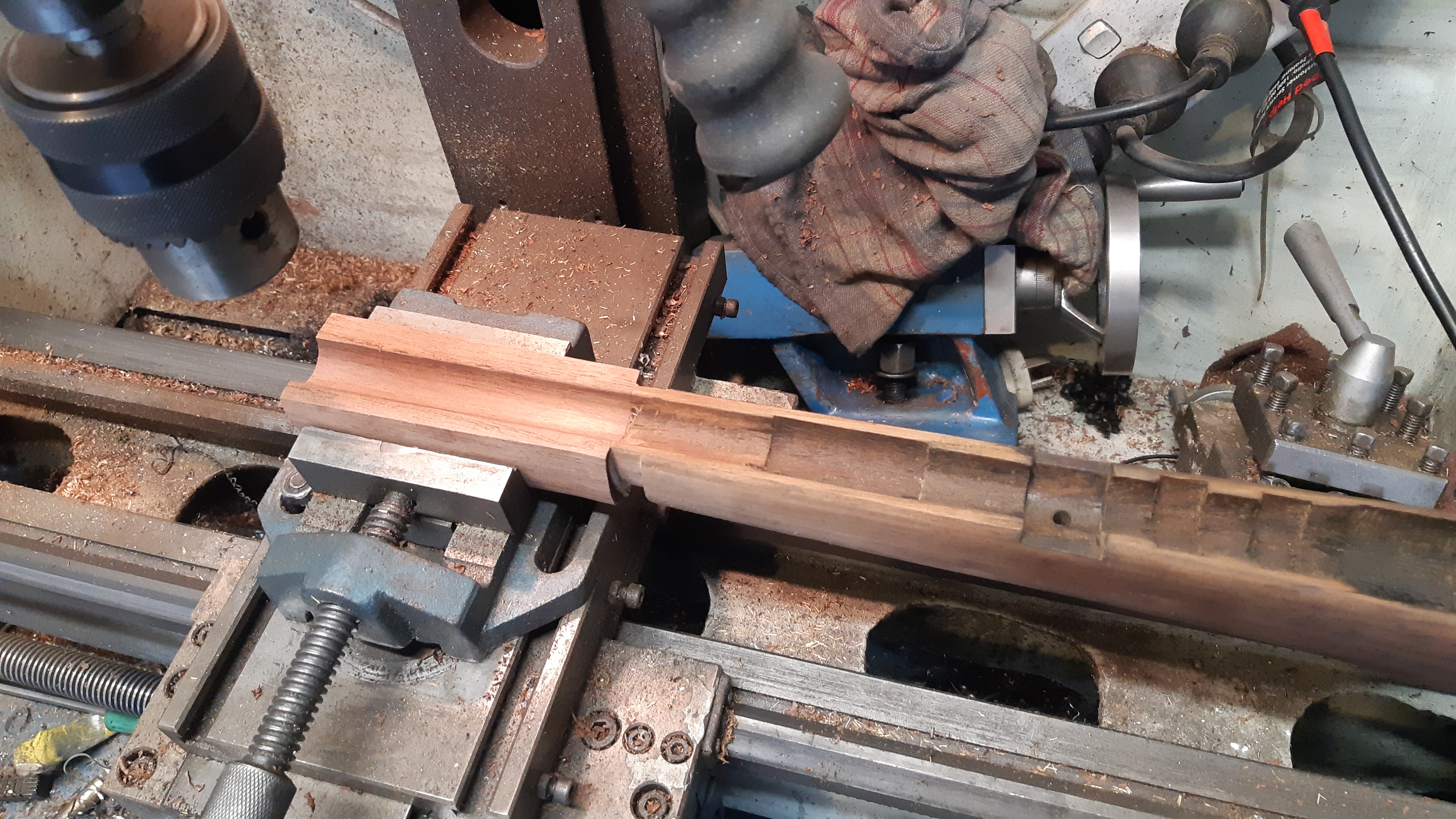

I cut a new barrel band groove closer to the rear sight where the sporterized wood was thinned to about the right size as what it would have been if it was full length.

I scratched through my walnut collection to find a plank that best matched the colour of the stock and then spent a considerable amount of time matching the cut direction and grain.

After cutting the front off the front of the new barrel band slot I glued on the new donor walnut extension to carefully hide the join under the steel barrel band.

After milling out the barrel channel the next mission was to cut out the nose cap inlet. Lots of measuring and chiseling later I got it fitting nice and snug.

Last but not least I had to make a new top wood to tie it all in. Ive seen people cut down original top woods to do this but other than a waste of good vintage parts I personally dont think it looks right.

Instead I cut another piece of walnut and matched the grain direction again.

The intention was to make a top wood with all the same shapes and angles of a full length top wood but in a miniature version.

I gave all the rest of the stock a careful tidy up and started the week long process of building up the linseed oil luster of the day.

I will throw together some loads for it and see how it shoots soon. I have some 150gr 174gr and 180gr to test.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 55

Thread: .303 Tank crew carbine

-

27-08-2021, 09:16 AM #1

.303 Tank crew carbine

-

-

27-08-2021, 09:29 AM #2

Thats awesome!

Thats really come up well, must have been a lot of work.

I hope it shoots well for you its a cool project."Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

-

27-08-2021, 09:35 AM #3Member

- Join Date

- Aug 2018

- Location

- Christchurch

- Posts

- 1,762

Fantastic work. That looks amazing!

Resident 6.5 Grendel aficionado.

-

27-08-2021, 09:40 AM #4Member

- Join Date

- Mar 2017

- Location

- Marlborough

- Posts

- 1,528

Epic job. Really nicely finished.

-

27-08-2021, 09:46 AM #5Member

- Join Date

- May 2018

- Location

- Porirua

- Posts

- 1,351

That look great. Well done that man.

Remember the 7 “P”s; Pryor Preparation Prevents Piss Poor Performance.

-

27-08-2021, 10:01 AM #6Member

- Join Date

- Oct 2018

- Location

- Manawatu

- Posts

- 188

Just brilliant! What a neat wee project.

-

27-08-2021, 10:08 AM #7

Damn, Nice work. I have a mid 40s Lithgow with a good barrel that is waiting for the same treatment. However, I am going to do away with the original rear sights and put an aperture on the charging bridge. my eyes barely handle aperture sights, let alone normal sights.

I believe the stock on mine is Coachwood, which I am struggling to find a match for.

-

27-08-2021, 10:42 AM #8

Thanks guys, a labour of love for sure.

I wasnt sure if it would please the masses or if I was going to get roasted by the originado elite of non matching number police..

At the end of the day if it was ever the intention to put it back to the true original form it would still need a new barrel, fore stock and top wood, the same three items it needed before I bubba'd it up.

-

27-08-2021, 10:57 AM #9

Thanks mate!

Post a pic of the wood you are trying to match, I have some 40s Lithgow Coachwood here that might do the job.

Beach can work too if you can find similar grain and stain it to match the orangey appearance of the coachwood.

Im on the look out for some more no1 mk3 walnut butts and sporterised fore woods in tidy condition that havent been hit to hard with the sander around the action area or butt. Thinning down forward of the rear sights doesnt matter.

I have a rear micrometer peep sight for this one that bolts in place of the safety catch if I ever decide to get competitive with it but still want to be able to use the charging bridge so avoided mounting sights there as some do. Actually looking for a handfull of stripper clips for it too. Funny the boxes of bits you have stored for years with these bits that you think you will never use and give most awy and have nothing left when you need it..

-

27-08-2021, 11:02 AM #10

Well done mate, awesome job

While I might not be as good as I once was, Im as good once as I ever was!

Rule 4: Identify your target beyond all doubt

-

27-08-2021, 11:21 AM #11

-

27-08-2021, 11:53 AM #12

Thanks for posting your talented work @Wingman Good lockdown medicine

-

27-08-2021, 11:59 AM #13Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,359

Nice work! There is something about shortened rifles that appeals to me.

-

27-08-2021, 12:07 PM #14

-

27-08-2021, 12:33 PM #15

Thank you Rod, me too..

While this one was a fun fullbore build my current builds are even more appealing to me.

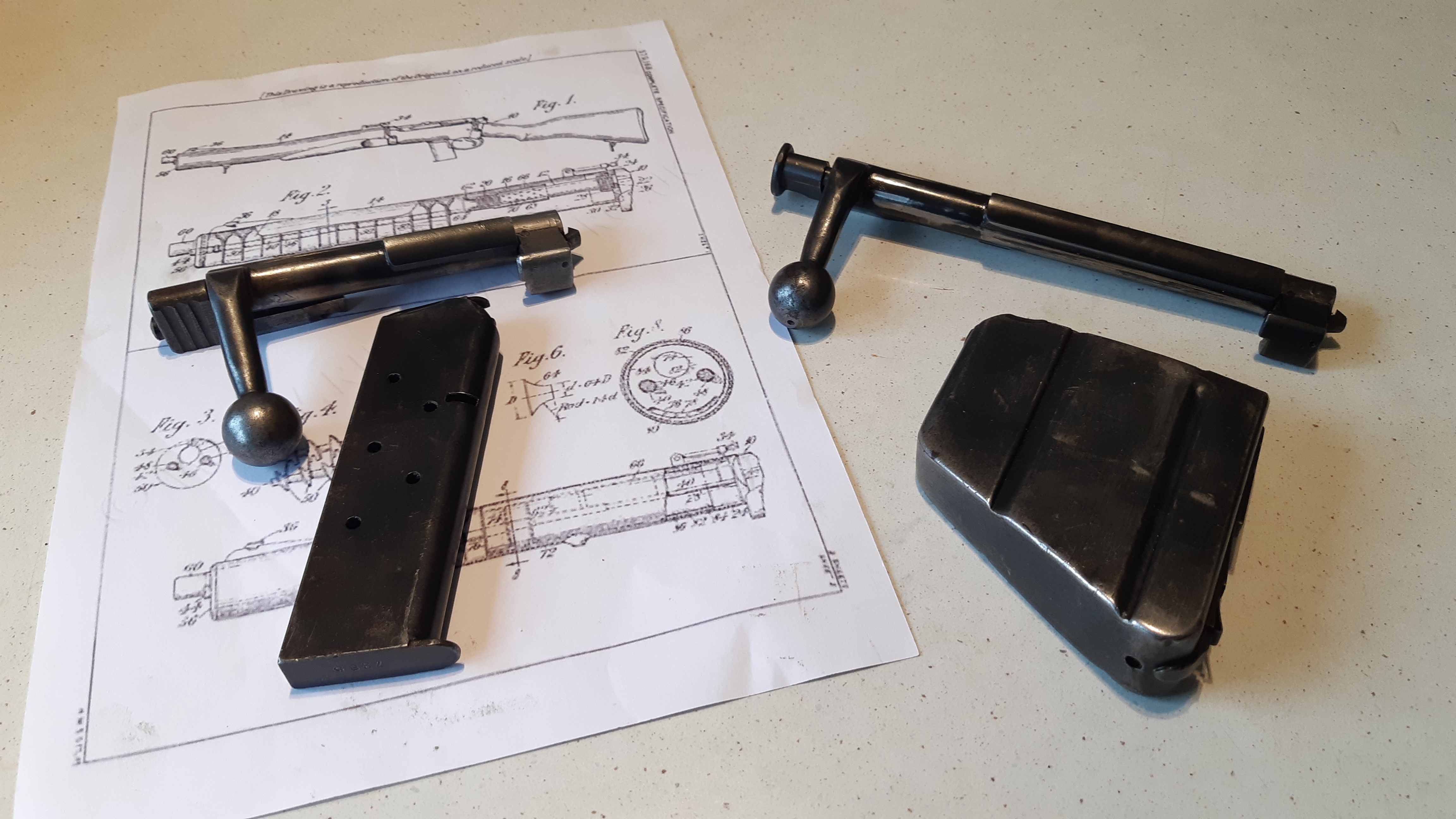

Picking up where you left off I have a run of Delisle Commando carbines on the go.

I have owned a couple of replicas over the years but unlike your beautiful builds they are never quite right in many ways.

Like yourself I have years of research and documentation and have compiled an accurate set of drawings and photos of the real thing so decided to finally have a crack at building some.

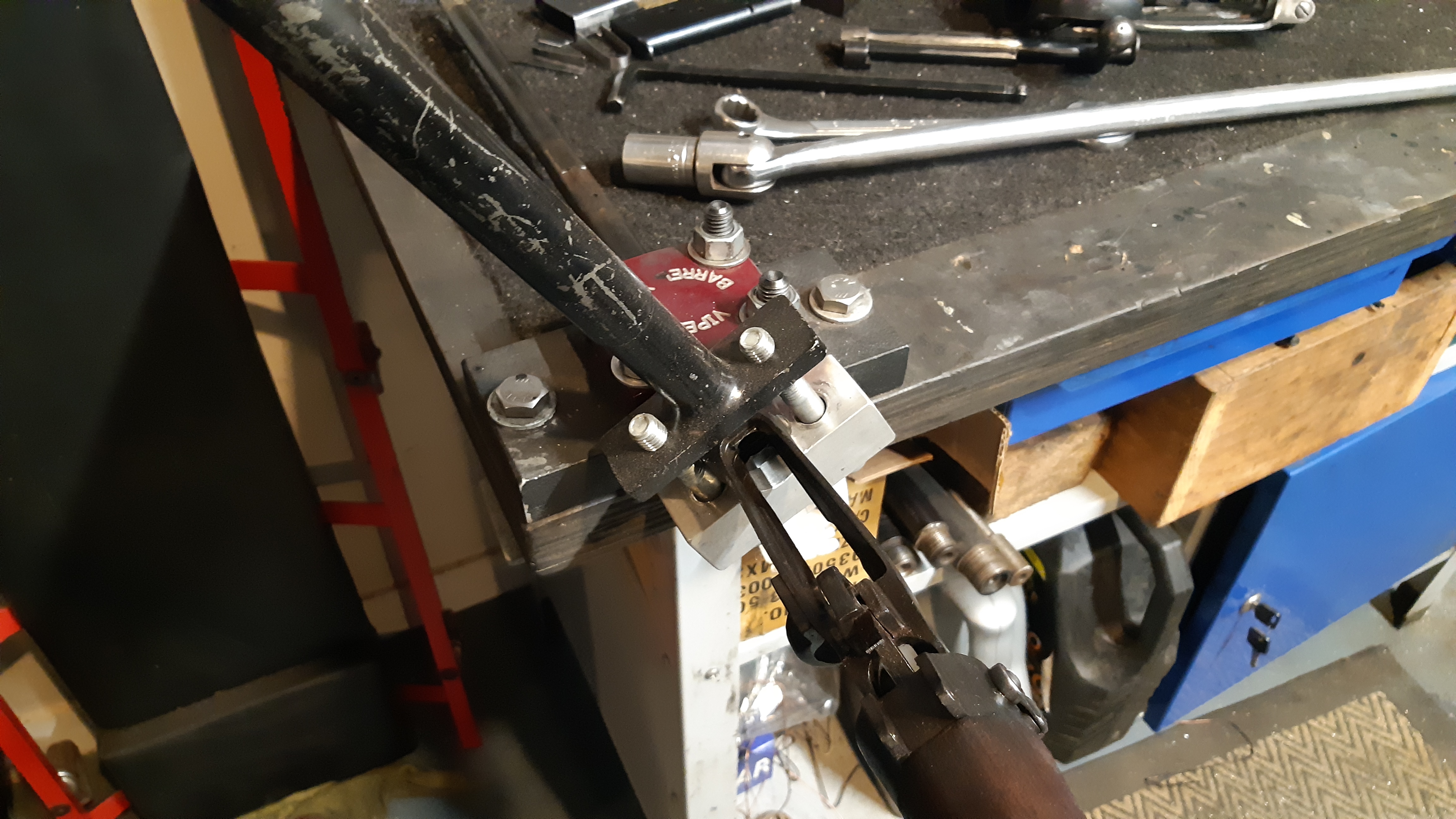

I have been busy making taps, forming dies, holding jigs and tooling for the various parts needed.

Other than a slightly longer barrel and 4 less baffles all hidden inside the suppressor to comply with the new law/meathod of measuring minimum length to end of rifling they will be as close to the real thing as possible.

Similar Threads

-

Vol Fire crew, who is one?

By smidey in forum VolunteersReplies: 360Last Post: 25-12-2022, 10:46 PM -

New crew

By bloobybob in forum IntroductionsReplies: 8Last Post: 30-04-2020, 07:50 PM -

Film crew?

By pops in forum HuntingReplies: 19Last Post: 28-10-2018, 09:14 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

173Likes

173Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks