“Brilliant. I’ve just bought 3 kilograms of rust, with a lump of wood on the end” I said to myself as I opened up the bundle that’d just been handed to me, wrapped up in an old dirty bathroom towel.

I’d been keeping an eye out for a restoration project for myself for a while now, and when I was offered a 1954 Remington 870 Wingmaster for next to nothing, I jumped at the chance. It was sold as “old, beaten up, put away wet and rusted to hell.” That sounded a little like me after a heavy night on the town, but for that price, I was keen to give it a go.

As I opened up the gently clanking package, I was really rather shocked. I’m the first to admit that I’m a little strict about my gun cleanliness, and what I was presented with made me sob a little. All I could see was rust. Red-ish-Brown, rust pitted metal.

Rusty Remington 870 Wingmaster

The first job was to take her down to bare metal to see how bad she was. A 30mins soak in a tub of malt vinegar, followed by a scrub with a wire brush, repeated as necessary, took the rust off in no time. It literally fell away from the gun, leaving a clean grey metal. A little pitted, but evenly so, giving the surface a not unpleasant texture. I then rinsed her off with water, and let her dry in front of the fire. The metalwork was then prepped with 400grit wet&dry paper.

Next, re-bluing. Yes, I know that there are a lot of great methods out there for coating your gun in this day and age. Hot-Bluing dip, baked-on-Duracoat, various milspec coatings etc. But these methods just didn’t seem right for the old girl. So I looked into the age old method of rust-bluing. Not to be confused with the modern methods of bluing metal that a lot of gunsmiths use these days, this was the ‘original’ method of bluing, and browning, guns throughout the centuries. It’s described as taking a lot longer, being much trickier than the new types of bluing, but the finish was prettier, and if done properly, would last a lot longer. The idea of ‘protecting my shotgun from rust, by using a layer of rust’ was rather interesting one.

There are plenty of products available for Rust Bluing; ‘Brownells Classic Rust Blue’, ‘Pilkington Classic American Rust Blue’ and ‘Laurel Mountain Forge: Barrel Brown and Degreaser’ are a few of the better selling ones available from The States. You wipe a thin film of the acid-mixture onto the metal work, and actually encourage the rust crystals to form by putting it somewhere moist. Shower rooms full of steam are a quick and lazy way to do this if you want to speed this step up, just be careful not to over do it. Yes, you’re purposely rusting your own gun. It’s a strange, nervous feeling deep down in the pit of your stomach. What you’re trying to achieve is near 95% surface rust. Any more and you risk the rust going too deep into the metal. Hang the pieces by wire, so that all the metal surface is in contact with the air. Once a thin surface layer of rust has formed, you then boil the metal part for 10-20mins in distilled water, or rainwater. This coverts the rust to a black rust or ‘ferro-ferric oxide’ as one website put it. A lot of town tap-water will not have such a good conversion effect. Latex gloves are a must – grease from fingerprints on the metal will not help rust to form, as well as a healthy paranoia about what may be in the rusting solution you’re using.

Finding a container big enough to boil a gun barrel isn’t an easy task, and walking into your local restaurant and asking them if they’d mind you using their kitchen to boil your shotgun isn’t likely to be met with much understanding. Luckily though, pouring boiling water over the parts in a tub is enough. 10mins of pouring a repeatedly boiling kettle and 3 pans of water from the kitchen hob over the metal work resulted in a deep black colour. ‘Carding’ the surface smooth with 0000 wire wool then takes off any excess, and smoothes out the finish. Wipe the parts down with nail polish remover to remove dust and any grease, and repeat the AcidSolution-Rust-Boil-Card cycle. Care must be taken when re-aplying the solution as it will actually strip off some of blue that you just carefully put onto the metal if you wipe over a patch you’ve already wetted. Smooth, single wipes with a cotton bud, and don’t be tempted to go back for any small spots you’ve missed – you’ll get them in the next coat.

Each cycle, the colour of the bluing will get darker and deeper. Different metals will react differently of course – the old soft shotgun metal on the Wingmaster only took 5 cycles before it was noticeable that she was very reluctant to form any more surface rust. I’ve been told harder steel may take up to 8 cycles. If your gun refuses to rust when coated in acid, that’s a pretty good indicator that you’re headed in the right direction. A long soak in hot water and baking soda to neutralise any acid and stop further rusting is the final step to this stage.

The final stage is oiling. Apply a very generous amount of Boiled Linseed Oil (great for wooden stocks as well) onto the metalwork with a rag, and let to sit for a few hours, before wiping down well. The residue should then be baked into the metal – 150degC for an hour. Once cooled and wiped down, do the same with mineral oil, 120degC for an hour. A big gas BBQ with a temp gauge was perfect, although a larger kitchen cooker would be fine. Note: It is vital to ensure that your wife is out for the day before attempting this, otherwise you risk unwelcome side effects.

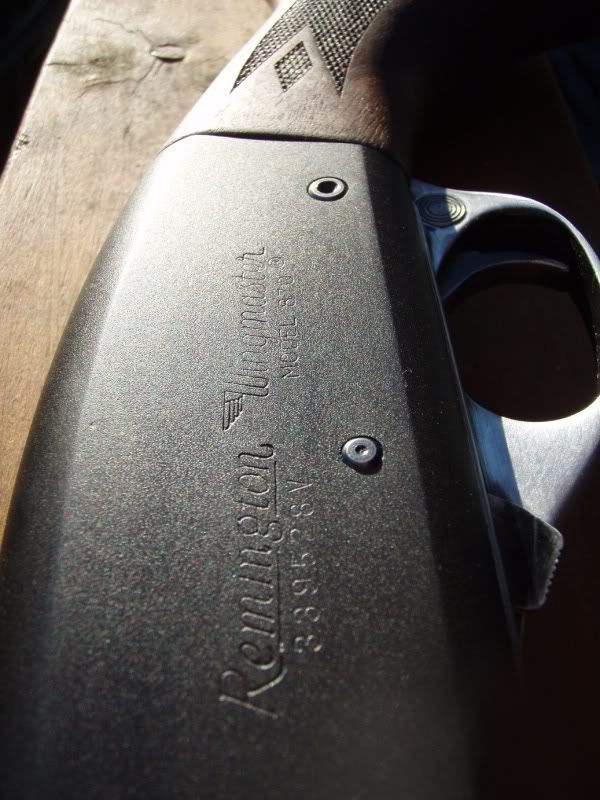

The finish came up a very even, deep black. When out in the sun, there’s a slight blue tint which adds a depth to the finish. To go with her new colouring, a new stock was bought from Remington, along with a new sight-bead. The trigger guard polished up to a dull silver.

And that, it a classically Rust Blued shotgun, with a baked in oil finish. A regular wipe down with your favourite gun oil will be enough to keep her looking good for decades to come.

UPDATE: 1 year later, and she still looks as good. I oil the metalwork a bit more often than my other guns, simply because she's Rust Blued, but that's it! I was surprised that the bluing has not worn away around the forend slide... It probably will given enough years of use, but so far, not even a mark on the surface.

I used Laurel Mountain Forge Browning/Degreaser for my bluing solution, and there was no hassle with them shipping overseas. If I spent $40 on supplies for the entire process (minus new bead and stock) I'd be surprised!

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 9 of 9

Thread: 870 Rust Bluing

-

24-09-2012, 08:02 PM #1

870 Rust Bluing

-

-

24-09-2012, 08:10 PM #2

Great report grue thanks

Just one question, What was the bore like?"Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

-

24-09-2012, 08:24 PM #3

I love that gun and the classic style of the blueing. well done. it looks awesome

-

24-09-2012, 08:48 PM #4

The bore was rusty... but only very minor pitting under it. An electric drill, cleaning rod, and some bore-paste brought it up a treat

-

24-09-2012, 10:01 PM #5

Looks great, you must be very pleased with the result.

kj

-

24-09-2012, 10:18 PM #6

What a transformation good work there

"Thats not a knife, this is a knife"

"Thats not a knife, this is a knife"

Rule 2: Always point firearms in a safe direction

CFD

tps://www.timeanddate.com/countdown/generic?iso=20180505T00&p0=264&msg=Dundees+Countdo wn+to+Gamebird+Season+2018&font=cursive

-

25-09-2012, 05:45 PM #7

Very nice! A good save from the scrap heap.

-

30-09-2012, 09:37 AM #8Member

- Join Date

- Mar 2012

- Location

- wellington

- Posts

- 468

nice one grue looks a treat now! have you ever tried using molasses for neutralizing rust ? works wonders

Remove Rust from Metal and Panels the Easy Way: Video 1 - YouTube

-

30-09-2012, 11:11 AM #9

That is very nice. Good job.

VIVA LA HOWA

Similar Threads

-

Anyone rust blued a gun before?

By Pointer in forum Firearms, Optics and AccessoriesReplies: 3Last Post: 18-03-2012, 06:12 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

6Likes

6Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks