Hi everyone, this is a project I recently finished.

The plan was to build a dedicated 22lr upper using a standard ar15 upper, a modified CMMG conversion bolt and a used Anschutz 520 barrel.

It started when I bought a stripped upper at the shot show for the great price of $100.

I then bought a CMMG 22lr conversion bolt with a couple of mags.

I already had the barrel, I had bought it a few years earlier for use on another project that never happened.

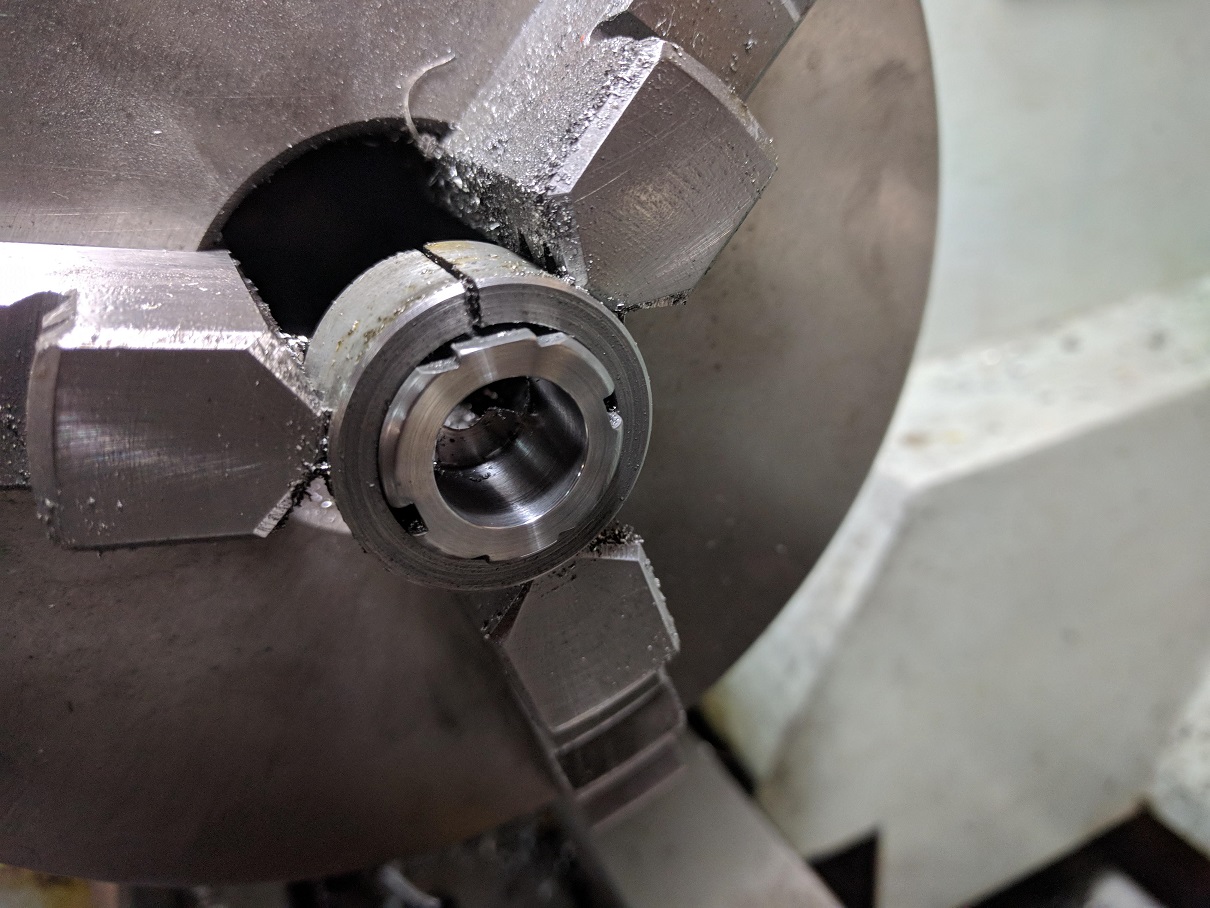

The first job was to strip down the bolt and hacksaw off the chamber adapter. (You can buy these without a chamber adapter but I could not find these in NZ)

Next, I mounted it in the lathe using a small bushing I made for the job and bored it out to 14mm. I bored deep enough that it just skimmed the back face of the feed ramp.

Next was to turn down the shank of the barrel to fit both the receiver adapter and bolt adapter

I made a collar for the barrel to adapt it to an AR-15 upper. This is to be glued in place and allows the barrel to be permanently mounted using a standard barrel nut.

The collar needed 2 cuts to allow for clearance of the bolt rails, this was a simple case of clamp it in the mill vice and run an endmill across it.

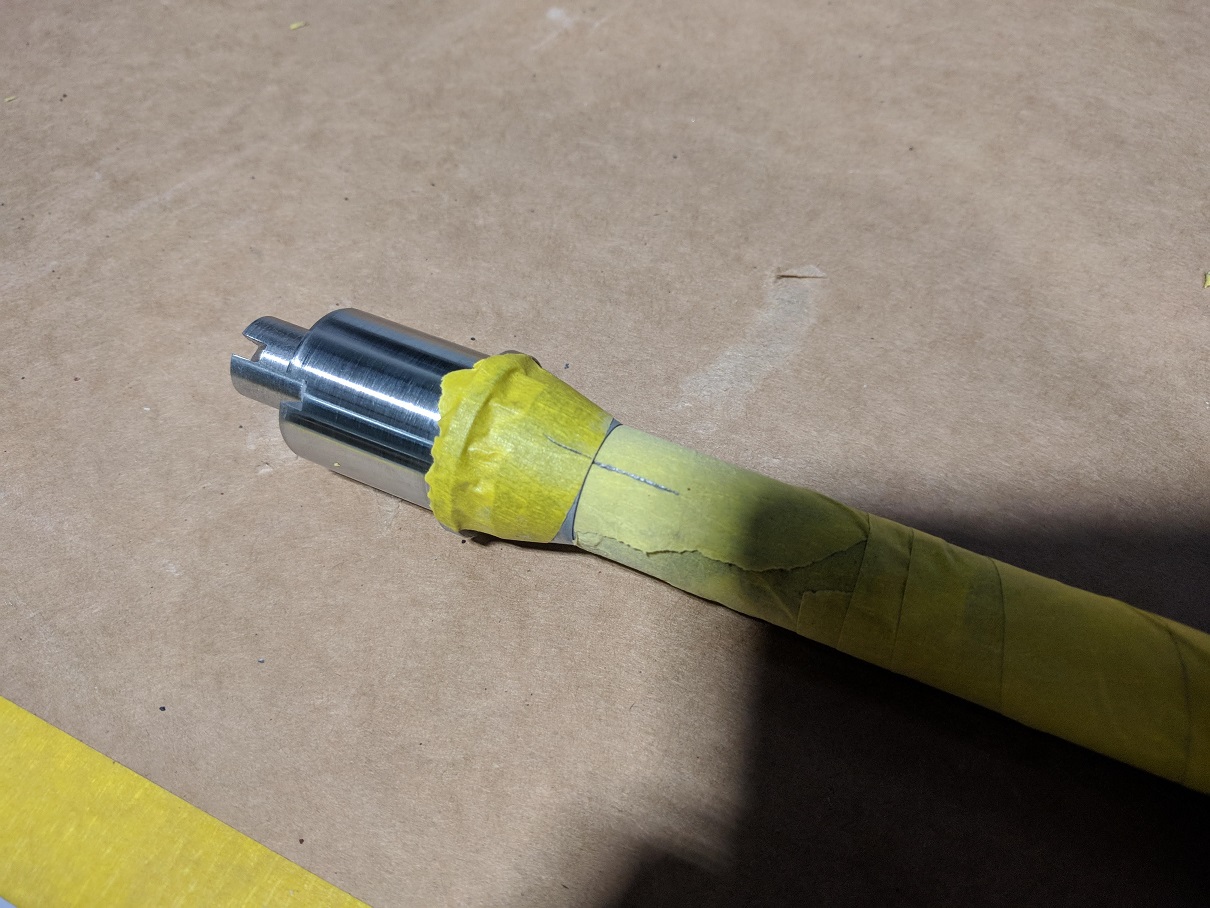

I then masked and sandblasted the collar and barrel shank and glued the two together using a thin epoxy.

Once cured I sandblasted the assembly and gave it a quick coat of black paint

Next was to make the handguard. I used a section of carbon tube that I picked up from work, cut it to length and sanded it back to 400grit. I will add vents and some textured grip at some point.

Once I had the handguard I could make a barrel nut to suit. A simple job on the lathe.

At this point I assembled the rifle and took it out the range for a test run. I was expecting a shit fight to get it running nicely but I put about 200 rounds through it without a single issue. Very impressed with CMMG bolts and mags.

I decided I wanted to thread the barrel and suppress it as it is just a touch too loud with subsonic ammo to shoot without hearing protection. Though I suspect most of the noise is likely the action cycling, I will suppress it anyway.

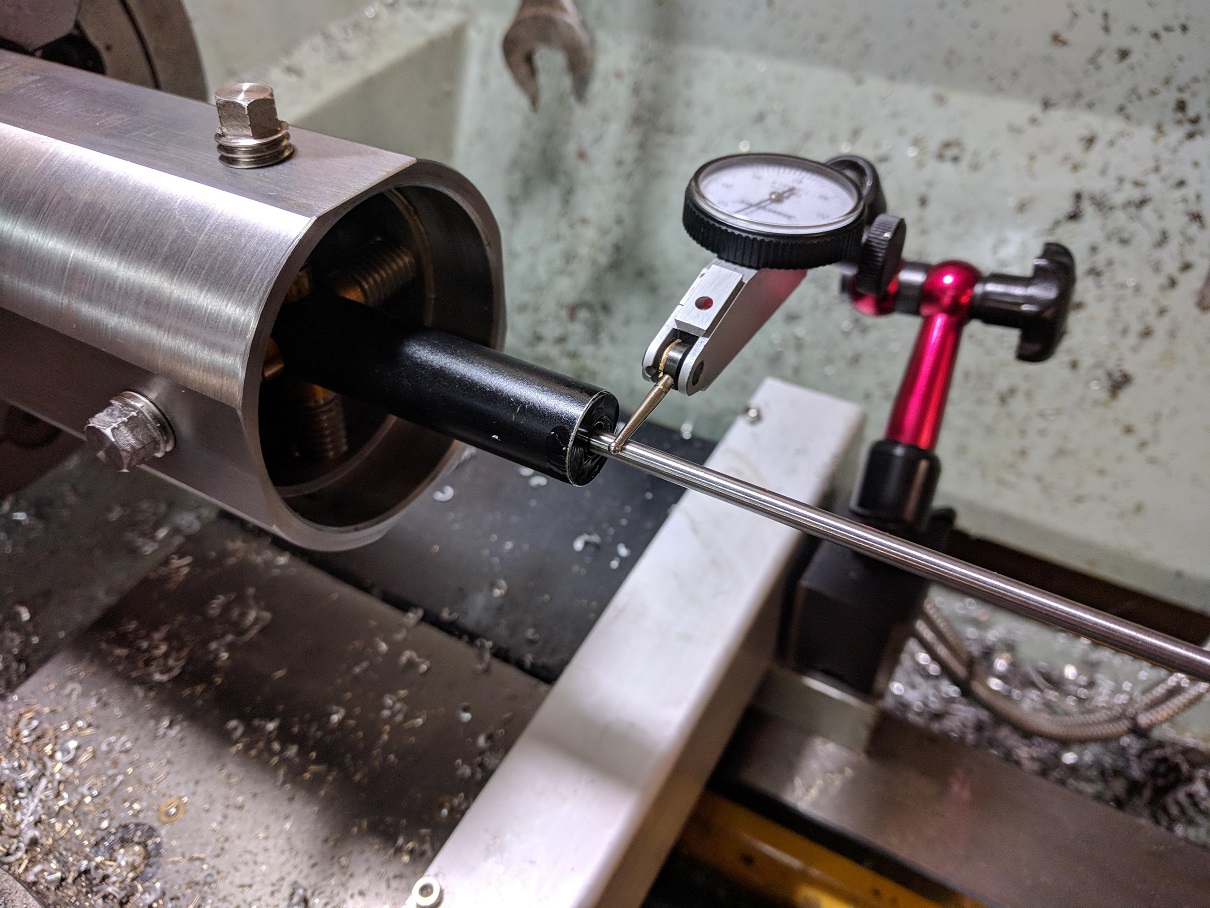

I set the barrel up on the lathe using my action truing jig as it is too short to put through the headstock. I dialed it in using a length of rod with a brass bushing, which would be just inserted into the bore, adjusted until running true and then advancing the rod about 100mm further into the bore and indicate again. Once both of these positions are showing no movement on the indicator, the bore is running true to the lathe.

I threaded it for 1/2-28

And here it is assembled. Not absolutely complete but very shootable right now. I have mounted a super expensive chinese red dot ($20, Ebay) and I am actually very happy with how it preforms. Perfect for a 22.

I intend to use it for Mini IPSC and Speed steel shooting. If it proves to be accurate enough, it may be used for long range 22 as well. I have checked the velocity with CCI Std and get about 1030fps

Thanks for looking.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 13 of 13

23Likes

23Likes

Thread: Ar-15 Dedicated 22lr upper, using CMMG bolt

-

31-08-2018, 11:33 PM #1

Ar-15 Dedicated 22lr upper, using CMMG bolt

-

-

01-09-2018, 10:10 AM #2

Super impressed, this forum never fails to produce some amazing workmanship and the pure ingenuity is just great! Would love to be able to do just a fraction of the work half of you guys can get done!

Sent from my iPhone using Tapatalk

-

01-09-2018, 11:28 AM #3Member

- Join Date

- Jan 2018

- Location

- kaiapoi

- Posts

- 7,366

Agree. Good set up you have there.

Just one question. You epoxied the collar one. why didn't you use a shrink fit? Didn't want to crush the chamber/barrel maybe?

-

01-09-2018, 05:59 PM #4

Nice work! What's the trigger?

Make sure to get a few spare firing pins, the CMMG do break them from time to time. Cheap as chips, but a pain to get at short notice.Identify your target beyond all doubt

-

01-09-2018, 06:46 PM #5

-

01-09-2018, 06:51 PM #6

Good tip, I'll be sure to track some down.

The trigger is handmade by me and is based closely on an Elftman drop in trigger. It works ok with 223 but has trouble igniting some brands of primers. Hasn't got a shit show of igniting 22lr. I need to mill out the trigger hanger some more to make room for a stronger spring.

Ar15 triggers are a bugger to build and I wouldn't try it again quickly.

-

01-09-2018, 06:56 PM #7

-

02-09-2018, 12:07 AM #8Member

- Join Date

- Mar 2015

- Location

- Auckland

- Posts

- 564

NICE!

mini ipsc... ASC member?

-

03-09-2018, 10:22 AM #9Member

- Join Date

- Apr 2018

- Location

- auck

- Posts

- 213

that's very awesome, i own a few of the cmmg bolts, how's the group?

-

03-09-2018, 10:58 AM #10Member

- Join Date

- Jul 2016

- Location

- Auckland

- Posts

- 107

Very nice, I like to see people doing stuff form scratch it cool to watch progress and a great result.

I have made a few of those handguards, the ~50mm carbon fibre actually feels really good and works for small and big hands.

@Glycerine I am at ASC, we have a grading match for mini rifle this month. hopefully see you there..

-

03-09-2018, 01:21 PM #11

-

04-09-2018, 06:41 PM #12

Not a member yet, but im thinking of joining in the near future.

I shot some groups with a scope attached and it looked promising considering the muzzle at the time was literally hacksawed off. I have not had it at the range since I threaded and crowned it, so it will be interesting to see how it shoots, and how much of a difference a crown actually makes.

Similar Threads

-

22LR CMMG kit to dedicated 22LR barrel adapter, anywhere selling them in NZ?

By steven in forum Firearms, Optics and AccessoriesReplies: 2Last Post: 22-05-2015, 09:21 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks