So here's the rough plan. In part posting to inspire others, but also hoping someone with more sparky knowledge than I will catch any problems with it before I put it all together

The plan is to wire a safe for light and reduce humidity. Would leave a 12v incandescent bulb running 24/7 in the bottom to raise the box internal temp to reduce humidity/tools rusting, and have the LED lighting kick on when the door is opened so I don't have to wear a head torch to see what's going on in there.

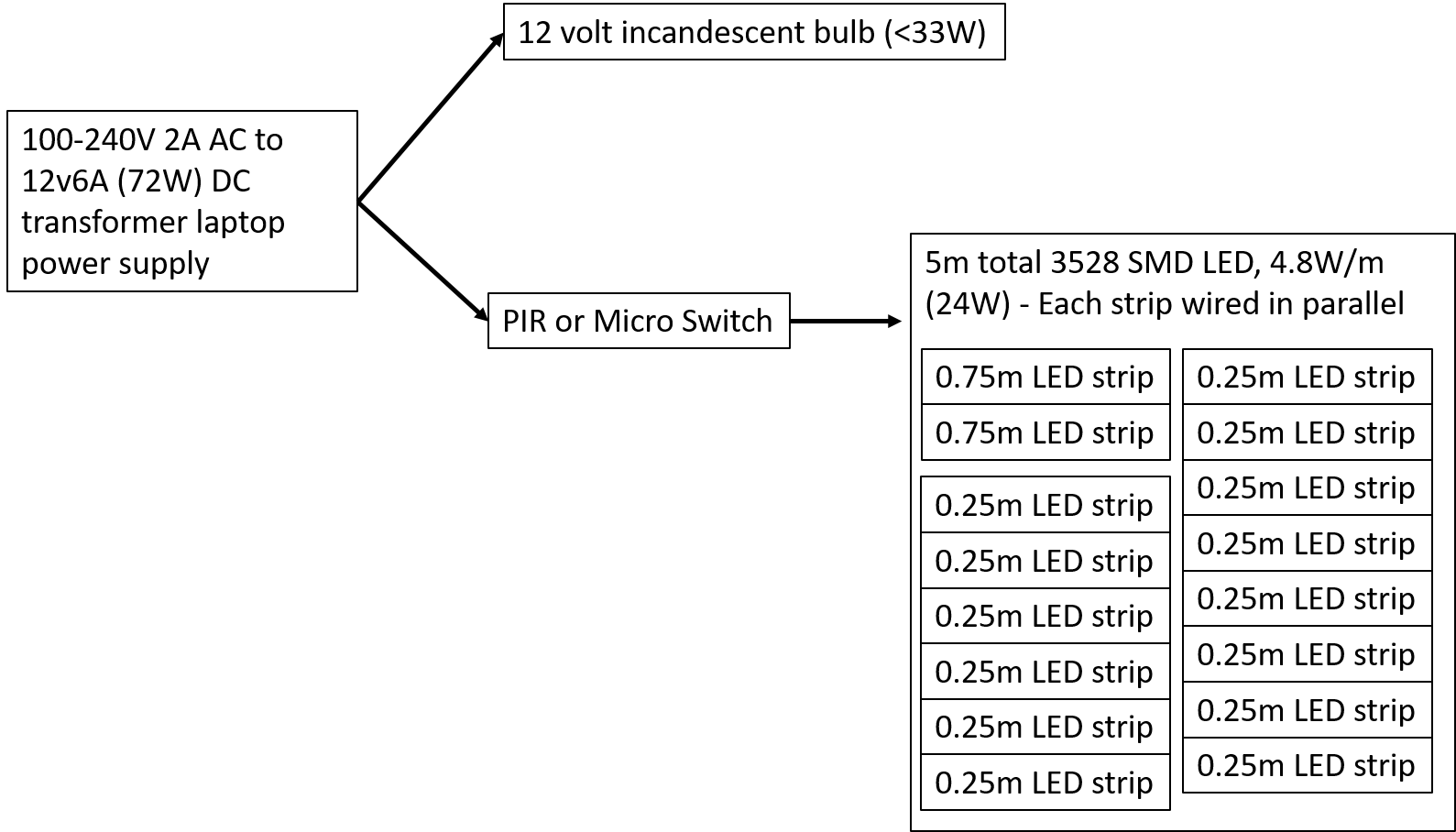

Have a roll of 12v LED strip lighting (3528 SMD LED, 4.8W/m) and am thinking of setting it up using a 12V 6A (72W) laptop power supply to power a small 12 volt (<33W) incandescent bulb (keep humidity in the toolbox down) and a bunch of LED strips (5m total (24W), with 14x 0.25m strips and 2x 0.75m strips wired in parallel) behind a micro switch or PIR to turn the lights on when the door opens and off when it's closed.

My thinking so far:

1) Power supply is 12V 6A = 72W. At 80% use to keep the power supply from overheating and dieing that's 57.6W

2) LED Strip lights are 4.8W/m x 5m = 24W

3) 57.6W - 24W = 33.6W maximum available for the incandescent bulb.

- Happy to change design, but still need to achieve the same end goals, preferably without spending a ton of money.

- I do want to make sure that I'm not overloading my power supply and it's safe to leave running 24/7.

Any input, comments, or modifications?

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 31

-

13-11-2020, 01:22 PM #1

Basic safe lighting and dehumidifying project

-

-

13-11-2020, 03:34 PM #2

Hmm,

DampRid Refillable Moisture Absorber 300g White Crystals

https://www.mitre10.co.nz/shop/dampr...stals/p/325507 $6.91

Blazing LED Timer Jumbo COB Light Bar

https://www.mitre10.co.nz/shop/blazi...t-bar/p/321919 $13.16

Job done unless you have some serious damp going on.GUN CONTROL IS A TIGHT 5-SHOT GROUP.

-

13-11-2020, 03:43 PM #3

The light bar is a good idea - if I weren't going for a powered dehumidifier I'd go towards battery, but figured since I'm running power for that might as well run the lights on the same system. Plus I already have all the components

I dislike the desiccant crystals. Had a desiccant pack swell, overflow its container and rust the heck out of the shelf and a tool next to it, which really put me off them. Plus once they've absorbed all they can absorb they stop working until you dry them out - if I'm busy I won't be checking it, so want something that's more active and reliable. There's an argument to be made whether a light bulb is more reliable, but that's a different issue I suppose.

-

13-11-2020, 04:41 PM #4

The light bars are little gems. Magnetic as well, so still it to the roof inside the safe and they provide more than enough light to do the job.

I only use the crystals in the safe in the garage which is not powered, but have the safe on the north wall which also makes a difference, I also throw a old blanket over the safe, not only does it assist with keeping it a bit dryer, if anyone snooping looks through a window, it isnt obvious to see.

Youre so lucky to have power available.

Cracking day today in Canty!

CheersGUN CONTROL IS A TIGHT 5-SHOT GROUP.

-

13-11-2020, 05:35 PM #5Member

- Join Date

- Nov 2014

- Location

- Christchuch New Zealand

- Posts

- 6,250

Rather than generating heat, in my last one I set up a bathroom extraction fan and an inlet vent at the other end. I then put this on timer to run for about a couple hours during the hottest and coldest parts of the day. Getting airflow and stopping the temp differential solved my condensation issues and fan run at much lower wattages than the power (I think the 5 inch one I used was about 15 to 20 watts, but I cannot remember.

-

13-11-2020, 05:38 PM #6Member

- Join Date

- Nov 2014

- Location

- Christchuch New Zealand

- Posts

- 6,250

Try one of those garden solar sensor lights. I chucked one in the garage and put the solar panel in a window. Like these, https://www.bunnings.co.nz/arlec-330...light_p0181802

Brilliant in the garage....

-

13-11-2020, 06:30 PM #7

I'm pretty far out of my depth, but aren't most laptop supplies voltage regulated not current regulated?

I agree that the LED's like stable current, though these light strips seem pretty tough, so I suspect because they're made for people like me it might tolerate things... or y'know... burn out

Have a DC PIR's off a defunct solar security setup similar to timattalon's that I pulled out of the bin (just need to check that it's still good)... I can just as easily run a micro switch though, just needs fiddling so it mounts properly.

For light I definitely prefer more light than less - some top down lights plus having some run down the insides of the door frame and underneath the cross bar supporting the barrels. Safes are already dark, plus dark guns, plus clutter, shadows, shelving etc etc and it sucks up the light. It'll be bright when it's installed, but once I pack it with junk I'm betting I still won't be able to see properly

Thought about that - then thought about a dehumidifier, but the hole I would need to cut in the safe would be a lot bigger than I want. Considered a grill too, but don't want to drag it out of its hiding place to do it.

Exactly that - I'm a firm convert to motion detecting light switches in transit areas like stairwells, hallways, enclosed porches, outdoor walkways etc. Can have them on PIR and then switch to on when you get to it, and switch to off when you leave, but you don't end up in the dark fumbling around because the PIR is working when the light isn't manually switched on. A 30-60s delay is usually all you need. It's actually what gave me the idea for the safe... dumb automation for everything!

-

13-11-2020, 07:29 PM #8Member

- Join Date

- Mar 2016

- Location

- Arrowtown

- Posts

- 1,349

I have a spare one of these if anyone wants it:

https://www.nuklearproducts.co.nz/co...at-foot-warmer

You can't cover them with anything but its worked well for me.

-

13-11-2020, 10:45 PM #9Member

- Join Date

- Nov 2014

- Location

- Christchuch New Zealand

- Posts

- 6,250

-

13-11-2020, 10:49 PM #10

-

14-11-2020, 07:16 AM #11

I have a couple of these set up in my safes,no drilling, power cords etc needed as dehumidifier is rechargeable and sensor light runs off batteries (×3 AAA)... light only $30.00 & dehumidifier $80.00... could be an option to look at ?

Sent from my SM-G930U using Tapatalk

-

14-11-2020, 07:40 AM #12Member

- Join Date

- May 2018

- Location

- Porirua

- Posts

- 1,342

You beat me to it.

https://www.alibaba.com/product-deta...477836463.html

Let the light be a light and control moisture separately.

Controlling temperature has its use though so how about a heat pad on the outside of the cabinet with a thermostat inside.Remember the 7 “P”s; Pryor Preparation Prevents Piss Poor Performance.

-

15-11-2020, 04:45 PM #13

Depends on the make/model of sensor, but yes, some do allow you to adjust for time (and sensitivity)

Someone posted about using a brewing drum heating belt a while back - seems like a neat idea. They seem to be a lot cheaper and more robust than other heat units on the market.

I do like the incandescent bulb idea because it's simple and cheap... most incandescents are something like 5% efficient turning electricity into light with the other 95% turning into heat... so really when it comes down to it incandescents are actually fancy heater units that happen to give off light rather than vice versa

So no one is seeing any glaring issues with the power supply, wattage, or wiring layout?

-

15-11-2020, 09:04 PM #14Member

- Join Date

- May 2018

- Location

- Porirua

- Posts

- 1,342

You are correct about an incandescent light bulb, I just thought putting a heat pad on the outside would be easier than drilling holes and you can use 230v stuff. I do recommend a thermostat as you’d be surprised how hot it can get.

What you are after is consistent temperature.

I have a heat pad that I used for home brew that you could sit you cabinet on also we use heat belts on refrigeration compressors and heat trace for freezer drains so there are lots of options.Remember the 7 “P”s; Pryor Preparation Prevents Piss Poor Performance.

-

15-11-2020, 11:27 PM #15

Similar Threads

-

LED Camp lighting

By Sarvo in forum Gear and EquipmentReplies: 21Last Post: 20-07-2019, 10:08 AM -

led lighting

By john worthington in forum Projects and Home BuildsReplies: 16Last Post: 19-04-2016, 10:40 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

21Likes

21Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks