Step four

Create the first mould half

A good layer of release wax is required now. Use as per the manufacturer instructions, I used 4 coats. Then a a good layer of heavy hold hairspray and you’re good to go

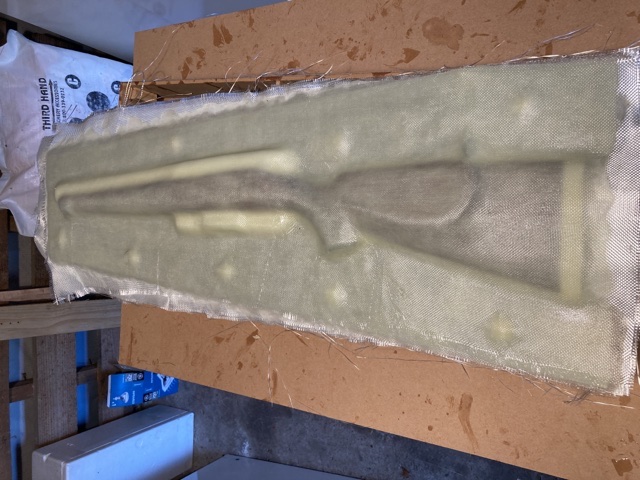

I used West System resin and hardener mixed with 406 silica filler to make a type of gel coat. This was brushed on all over the stock and parting board, creating a decent radius in all the sharp edges. This is critical to ensure there aren’t any voids in these areas, as the glass won’t conform to the sharp angles.

Once that has tacked off (is sticky to touch but doesn’t transfer to your finger/glove) use 6 layers of 200gsm plain weave fibreglass to cover the first half. Make sure you work all the air bubbles out with a stiff brush and or a roller. You’ll probably have to make cuts in the cloth to get it to conform to the stock shape (especially around the pistol grip) but you’ll work it out. Just be sure to make cuts of subsequent layers in slightly different places so the laminate remains strong.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 1 to 15 of 38

Threaded View

-

29-05-2021, 10:42 PM #3Member

- Join Date

- Aug 2019

- Location

- Manawatu

- Posts

- 1,055

Last edited by Hunter_Nick; 29-05-2021 at 10:48 PM.

Similar Threads

-

Shotgun Stock CNC Build

By Skirch in forum Projects and Home BuildsReplies: 23Last Post: 30-04-2021, 07:36 AM -

Wooden stock build

By Remmodel7 in forum Projects and Home BuildsReplies: 3Last Post: 03-03-2020, 09:57 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

99Likes

99Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks