Now that I am doing more gunsmithing work, I am finding myself with the need of a test tube for function testing rifles and also reloads without having to make a trip to the range. I want to be able to fire anything up to a 338LM and have it be safe.

I cant find much info online about these, so have made up a plan based on what little I could find.

My idea is to use a length of 200x200x9 square hollow section as the body, 1200-1400mm long. Weld a 20mm thick plate to the bottom. Then drop a layer of conveyor belting to the bottom with a piece of AR500 plate sitting on top of that. Then fill with about 600mm of sand (or rubber mulch, but I cant find a source), and have another layer or two of conveyor belting sitting on top of that to reduce the sand flying everywhere and sandblasting barrels. The idea is that if anything makes it through the sand, it will hit the AR500 plate, which has some cushion due to the conveyor belt under it. It would have about 500-600mm of free space before the sand for the muzzle to be placed and have room for a suppressor. The top lid would be a heavy rubber layer that would seal tightly around the barrel, with a steel door with a cutout to allow barrels through that can latch down. The whole thing would likely be wrapped in carpet or something to reduce the ring.

The idea is to have it as quiet as possible so I dont piss off the Mrs or the neighbors. I am on the outskirts of town, but still have close neighbors and the workshop is right beside the house.

Have any of our resident Gunsmiths (or anyone else) build one themselves and have any recommendations? I have taken a guess at what will work, but haven't dealt with this type of thing before, so its a fairly uneducated guess.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 16

-

05-01-2025, 08:40 AM #1

Building a test fire tube / bullet trap

-

-

05-01-2025, 09:53 AM #2Member

- Join Date

- Sep 2013

- Location

- Taupo

- Posts

- 1,634

A now no longer there gunsmith on the North Shore used a piece of 6" sch40 pipe about 1200 long with the lower half full of sand.

Sealing around the barrel was via a pillow wrapped around it.

From outside the workshop there was a "whomp" that was noticeable, but not obnoxious.

-

05-01-2025, 10:15 AM #3Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,351

My inner-city bullet trap was an old 45kg gas cylinder with a 20mm plate welded on the bottom, about 300mm of crushed gravel then filled to halfway with dry sand. I had a short steel tube in the top with heavy rubber sheet attached at each end with a 25mm hole. It sat on a frame that held it at 45 degrees and I got over 20 years of regular use out of it. I also had a 12mm steel scroll-shaped bullet trap that handled all rimfire and pistol calibres for 10 metre zeroing. Firing was done in enclosed shooting tunnel with an extractor fan for the fumes.

-

05-01-2025, 10:28 AM #4Member

- Join Date

- Mar 2012

- Location

- South Waikato

- Posts

- 8,582

An old oxygen (large) filled with sand and something to dampen the noise.

Dive bottle works alright for smaller calibers.Overkill is still dead.

-

05-01-2025, 11:41 AM #5Member

- Join Date

- May 2023

- Location

- South

- Posts

- 820

whats the legality of using bullet traps inside residential areas?

curiosity only.

-

05-01-2025, 12:22 PM #6

I did the hole for a mate using my post hole borer and the strainer auger. Extending the auger shaft I got a 1.8m hole. I bored it at a roughly 45 degree angle. The bottom was soft clay. All this in his lock up walk in safe in his basement. He then put a spiral welded pipe down and partly filled with layer of sand (not much) at the bottom. The top of the pipe was roughly 1/2m out of the ground so effectively an over 2m tube. Capped the top with a wooden cap with a barrel sized hole (~30mm , no damage to barrels). He never got any blow back and the noise was a muffled woomp which couldn't be heard upstairs in the house. The noisiest part of the deal was boring the hole in a confined space.

I did a similar thing for myself, but unlined, and capped with a concrete paver with a suitable hole in it. Same depth. Beside my hay shed. I used it to fire 2 fowling shots before heading off to my fullbore club days. My animals never even looked up from eating when I fired into it. Unfortunately when I went to use it for the start of a new season I got showered in muddy water and mud even went up the muzzle. The hole had basically collapsed over the off season and filled with water! I intend doing another up by the house where the groundwater shouldn't be a problem.

-

05-01-2025, 03:32 PM #7Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 6,179

A snail or spiral trap like Gundoc suggested, but with the addition of a water flush going around the inside of it with a pump pushing the water around. The water minimises contact from the bullet to the wear surfaces, absorbs junk and dust, and quietens the whole thing down. It's like a water theme park ride for the bullet, around and around she goes until it runs out of momentum... I think it might have been McColl that used to have one of these in Auckland, seen it used once.

-

05-01-2025, 03:50 PM #8Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,351

-

05-01-2025, 05:59 PM #9

When you do the above techniques, also turn on the air compressor or a bandsaw. Nobody will bat an eye at the "garage noises"

-

06-01-2025, 07:26 PM #10

Made a start today. I picked up 1.2m of 200x200x9 square hollow section plus had the steel shop plasma cut a 20mm plate for the bottom. I fired up the arc welder and glued the plate to the bottom of the SHQ. I'm no welder, but it won't be going anywhere and I got a couple of satisfying beads where the slag peeled off in one piece.

I'm thinking of putting some wheels on one end and some tip out legs so it lives standing up in a corner and is then tipped over on a 45deg for use and can be moved around. I have a very small work space at the moment, so every little bit counts.

-

06-01-2025, 08:51 PM #11Member

- Join Date

- Jul 2012

- Location

- Timaru

- Posts

- 884

you will get splash back. maybe add a few layers of belt on top of the sand that the pill will got through

CNC Machining

Hgprecision.net

-

06-01-2025, 10:35 PM #12

-

06-01-2025, 11:27 PM #13Member

- Join Date

- Nov 2014

- Location

- Christchuch New Zealand

- Posts

- 6,261

I would look at some carpet or similar around the outside as the rigid steel will act like a drum when it comes to the noise....a softer liner inside would also help (Ply or truck mudguard or similar).

Intelligence has its limits, but it appears that Stupidity knows no bounds......

-

07-01-2025, 11:18 AM #14Member

- Join Date

- Aug 2012

- Location

- helensville nz

- Posts

- 4,740

maybe a little door in the front with a hole just big enough to slip the muzzle of the firearm into

this will deaden a bit more noise than just simply firing the rifle into the end of the tube

make the hole trap into a giant suppressor

-

07-01-2025, 08:00 PM #15

I spent a bit more time on this today in between feeding the CNC.

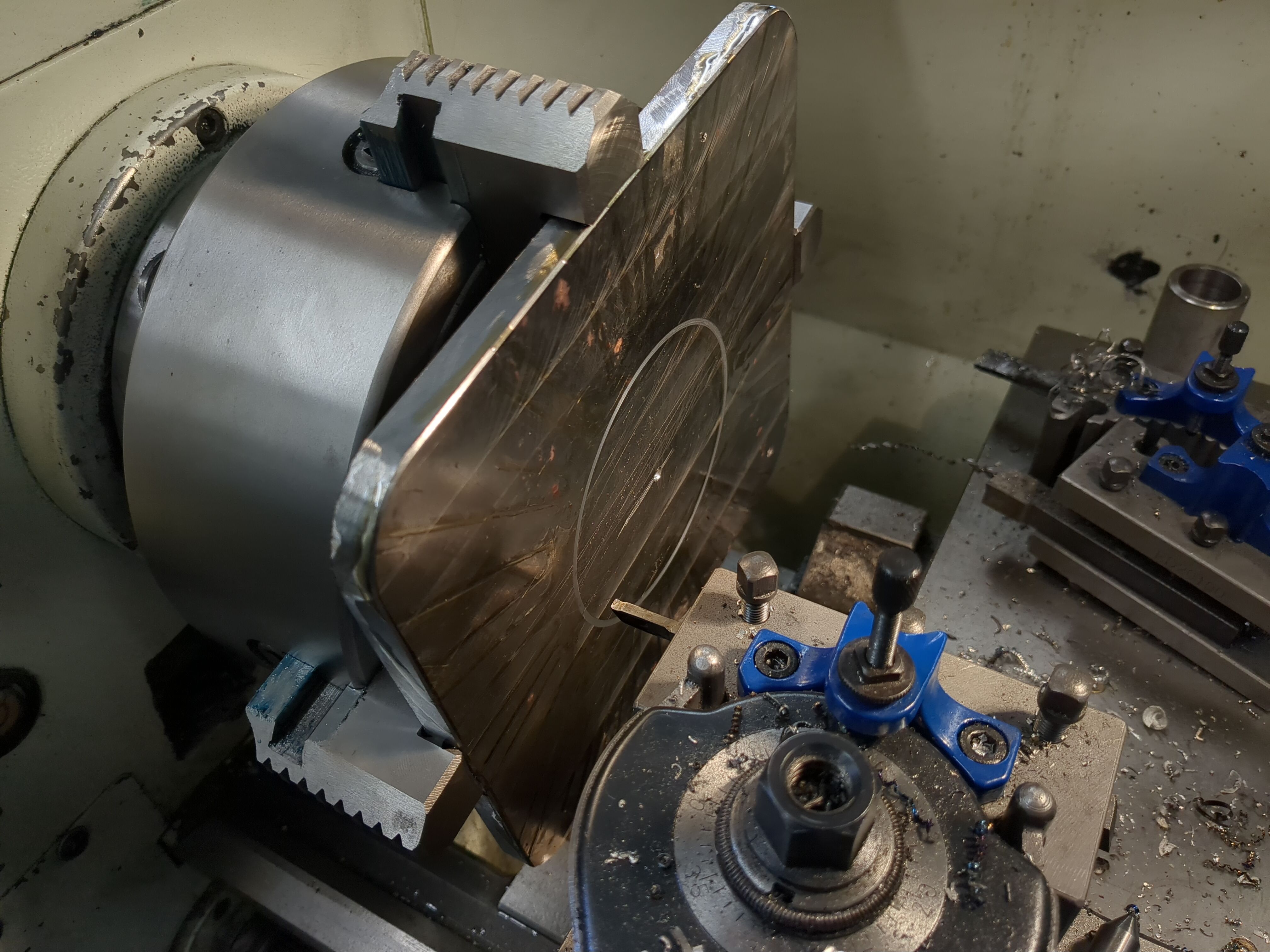

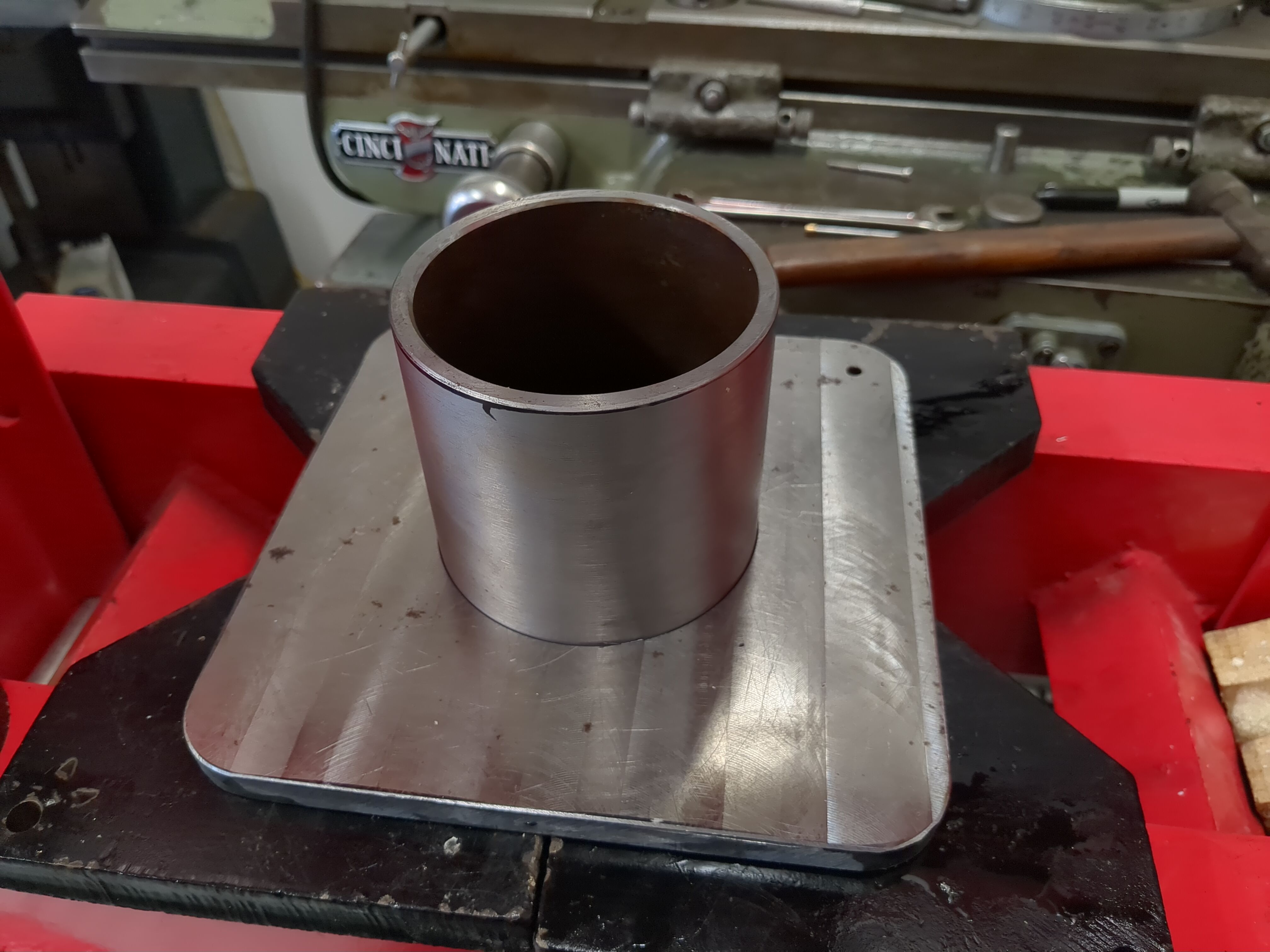

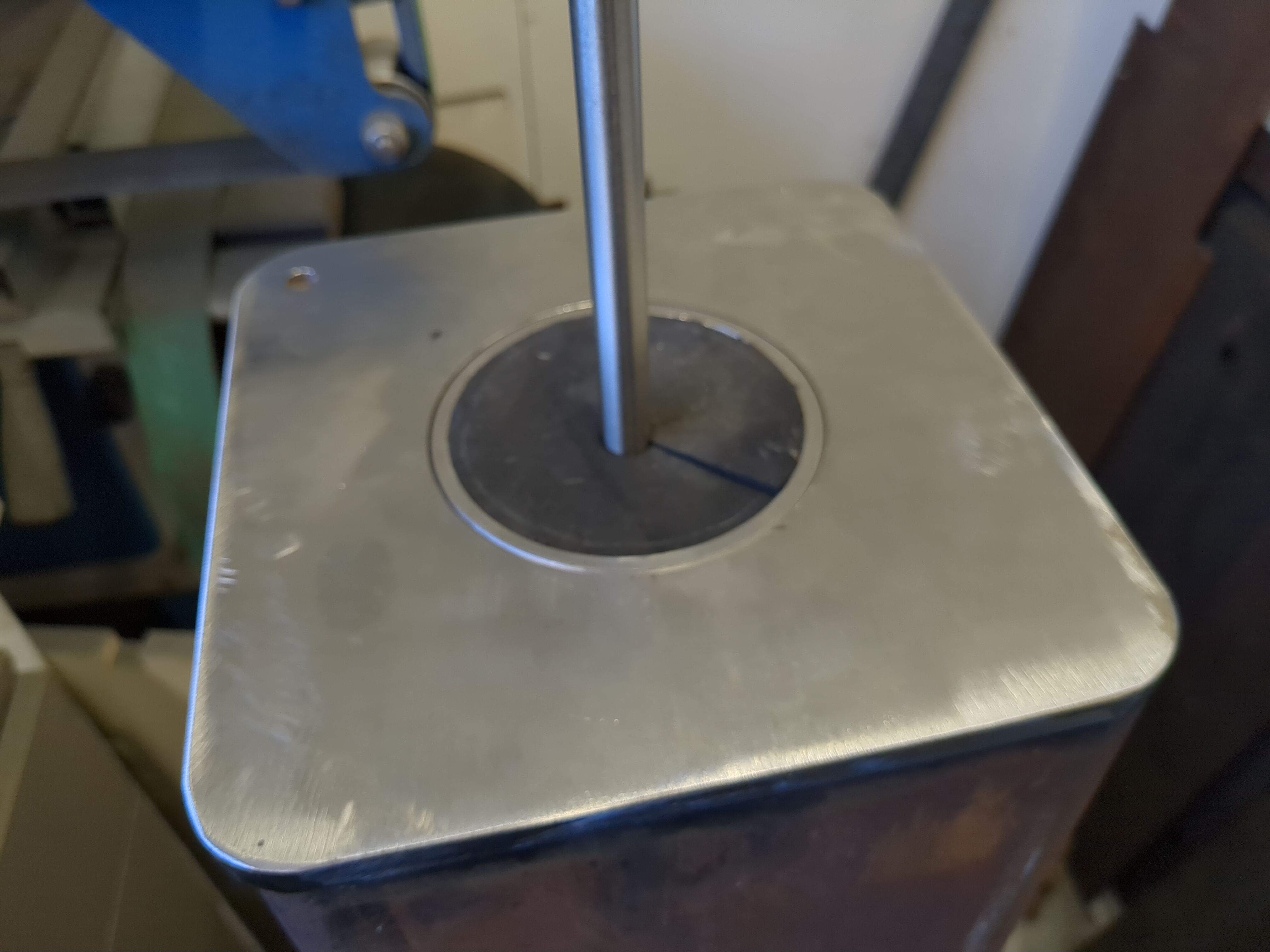

I found a handy bit of thick wall tube in my scrap bin, along with a piece of 10mm plate large enough for the lid. I turned the tube to a consistent diameter and then cut a hole slightly smaller in the lid using a face grooving tool in the lathe. The two were then hydraulically pressed together. I might add a few weld tacks to the underside just to be safe.

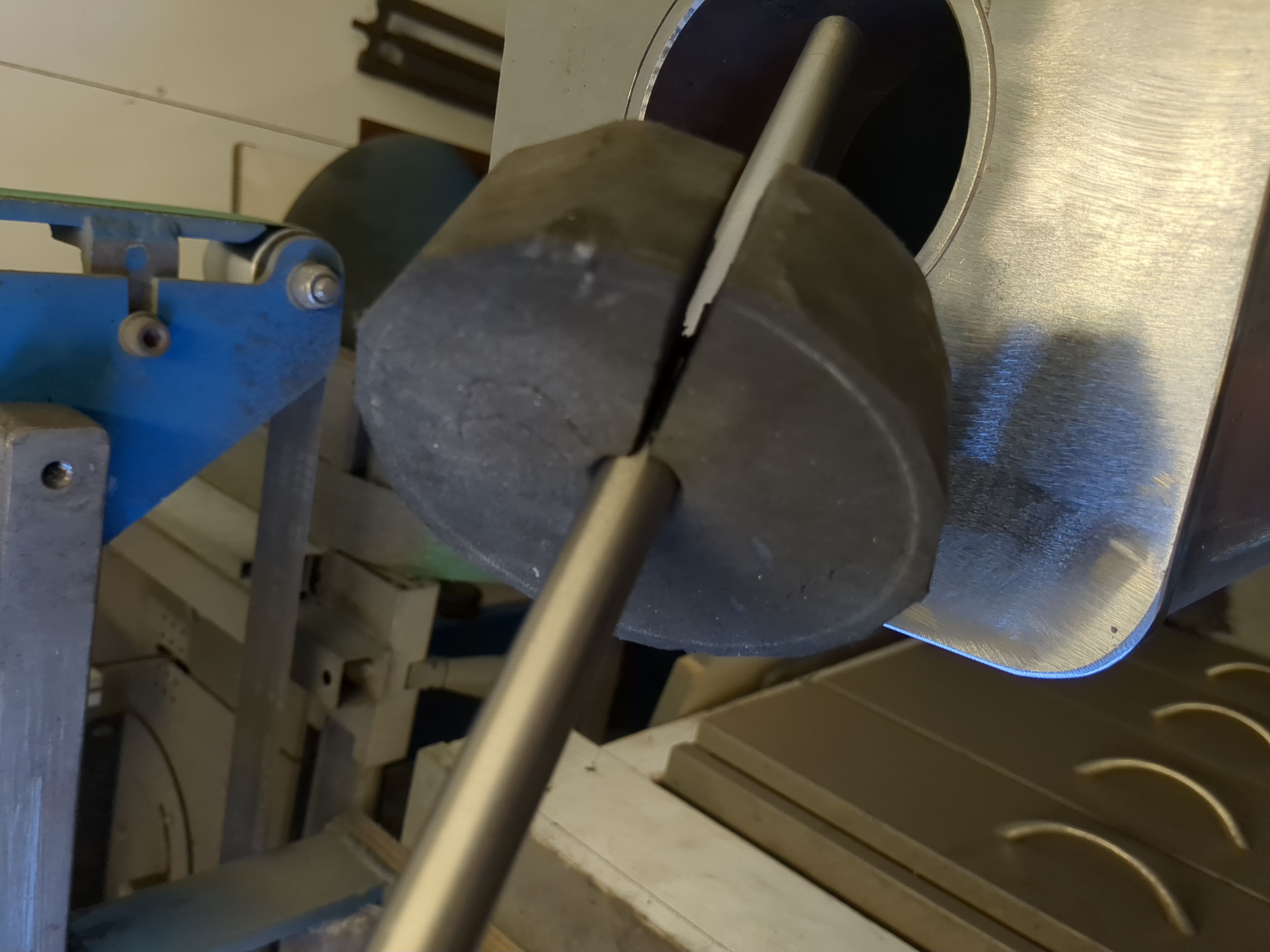

I then made a foam plug that is oversize and tapered, the idea is that it gets slipped over the barrel, then forced into the hole, hopefully sealing it tight. I may do a couple of these.

I was thinking of attaching a hinge and toggle latch to the door, but since the wall thickness of the SHS is 9mm, I may just drill and tap that and bolt the lid down. I don't envisage needing to remove it often.

I am planning to line the inside with the self adhesive sound deadening vinyl used in car rebuilds to reduce the bell effect. I may also wrap the outside with carpet, I'll do some testing and find out.

Might be ready for a test fire tomorrow.

Similar Threads

-

7mmSaum test fire

By Tahr in forum Firearms, Optics and AccessoriesReplies: 28Last Post: 01-11-2019, 06:24 PM -

Leapers UTG 3 - 12 x 44 compact scope. Review and Test Fire.

By Bagheera in forum Firearms, Optics and AccessoriesReplies: 2Last Post: 03-07-2016, 12:10 PM -

Interesting idea for a bullet trap

By Kscott in forum ShootingReplies: 2Last Post: 20-01-2016, 08:37 AM -

Test fire: shooting through tape on a suppressor

By Bagheera in forum ShootingReplies: 49Last Post: 03-08-2015, 09:37 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

30Likes

30Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks