@Mick Hunter yep its 3mm thich Ali angle. I threaded all the holes to make it easier to bolt up.

Lets see some other creations!!

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 61 to 75 of 97

Thread: DIY Induction Annealer

-

08-07-2020, 03:00 PM #61Member

- Join Date

- Jul 2012

- Location

- Tauranga

- Posts

- 2,637

-

-

25-07-2020, 12:23 PM #62Member

- Join Date

- Nov 2016

- Location

- Orewa

- Posts

- 86

I have moved all the induction annealer build documentation, parts list etc. to a more permanent website as my dropbox links keep getting broken.

https://www.mgnz-makes.com/

-

23-09-2020, 06:00 PM #63Member

- Join Date

- Nov 2016

- Location

- Orewa

- Posts

- 86

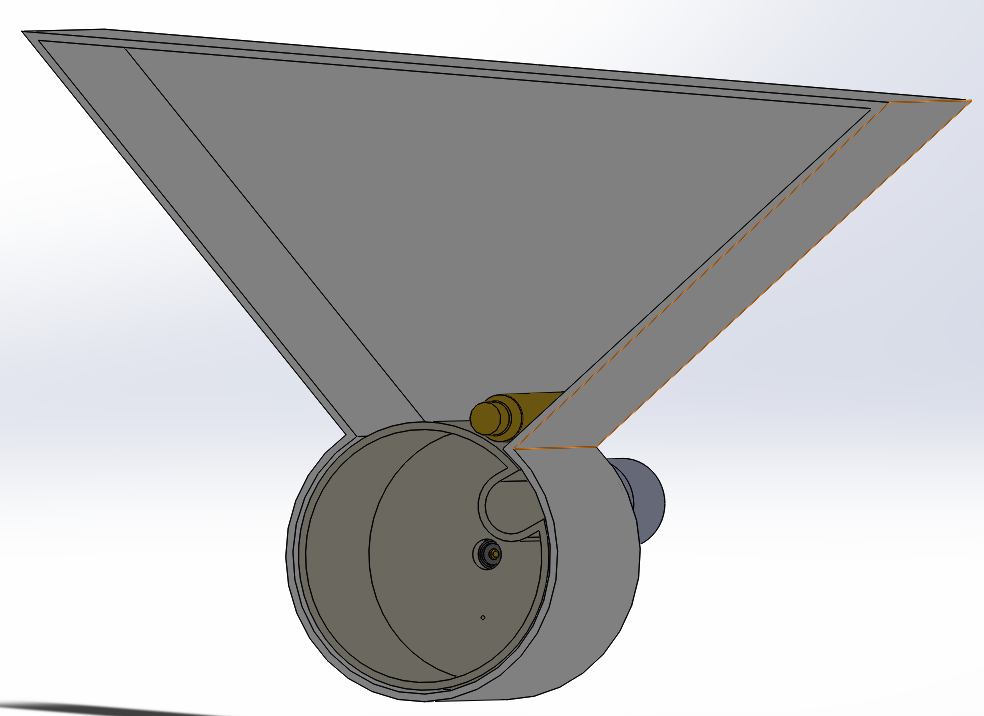

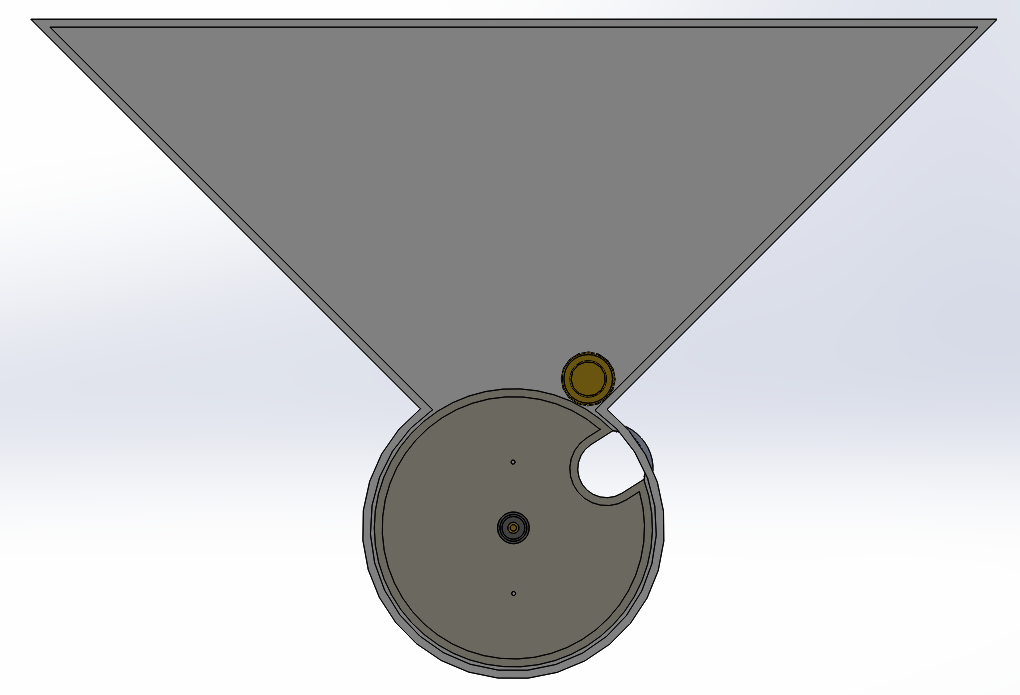

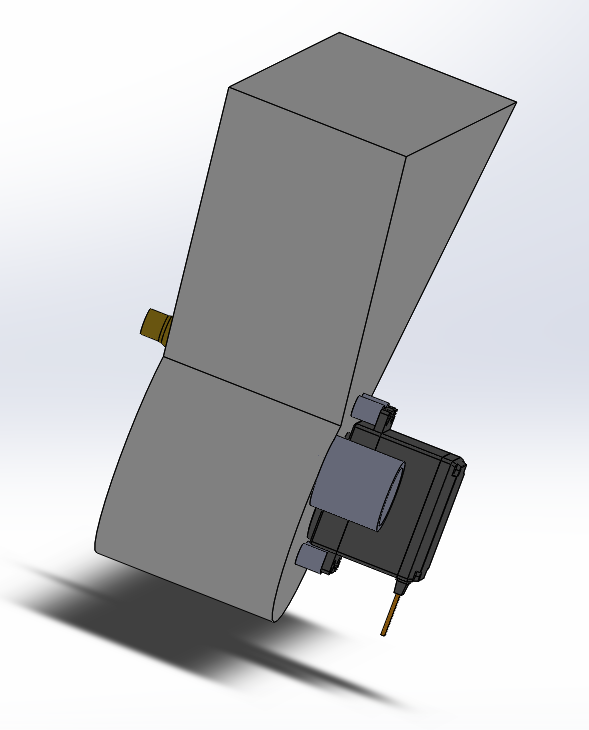

Quick update on this project. I'm starting to work on an automatic case feeder design add-on for the annealer. The plan is to 3D print the parts and provide the CAD for others. The feeding mechanism is going to be driven by a single servo connected to the arduino and synchronised with the free-run mode in the software. The case will be picked from the hopper and then dropped down a tube into the annealing coil.

This is the start of the CAD:

-

23-09-2020, 06:19 PM #64Member

- Join Date

- Mar 2016

- Location

- Arrowtown

- Posts

- 1,349

Nice. I look forward to seeing how this develops.

Good thinking @MGNZ

-

01-10-2020, 08:21 PM #65Member

- Join Date

- Nov 2016

- Location

- Orewa

- Posts

- 86

Still have a few feed bugs to work out, but not bad for a first run.

https://youtu.be/BujviMWKw0o

-

01-10-2020, 08:51 PM #66Member

- Join Date

- Nov 2016

- Location

- Orewa

- Posts

- 86

Much better feed reliability with 260 cases.

https://youtu.be/NZUAKkAxfk4

-

01-10-2020, 10:36 PM #67Member

- Join Date

- Mar 2016

- Location

- Arrowtown

- Posts

- 1,349

Clicked "like" but was thinking we need an "excellent" option instead.

Nice work.

-

01-10-2020, 10:43 PM #68

-

02-10-2020, 08:37 AM #69Member

- Join Date

- Nov 2016

- Location

- Orewa

- Posts

- 86

Yeah, was thinking the same thing. Or widening the slot a bit to accept slightly skewed cases. The orange outer wheel is removable without tools to allow for different case size versions to be swapped out.

Also noticed that 4 of the 300WM cases will bind across the top of the wheel - whereas the 260 doesn't. May also be contributing to the problem.

Slowing the servo sweep might also help a bit too.

-

17-01-2021, 12:16 PM #70Member

- Join Date

- Nov 2015

- Location

- Waikato

- Posts

- 744

Question for those that have done their annealers.

What wall thickness copper pipe did you use for your coils? I bought some 1/8 copper tube that has a 30 thou wall thickness and the pump won’t pump through the coil. It pumps fine through everything else.

Have just ordered some other 1/8 tube with a 14 thou wall thickness from a hobby shop which will give me more volume / less restriction through the coil.

Anyone remember what you used?

-

17-01-2021, 04:10 PM #71Member

- Join Date

- Jul 2012

- Location

- Tauranga

- Posts

- 2,637

@Mick Hunter I used 1/8 (3.2mm) with a wall thickness of .03 thou (.76mm).

Works good, maybe your pump isnt up to that? Can you blow through it? you can probably get it to gravity feed too. I have made 4 coils with this dia pump works on all of them.

https://www.aliexpress.com/item/4000...1c674c4dtYpyNP

Watch you dont flatten the thinner wall tubing, try getting it warm when you start bending it.

-

18-01-2021, 09:33 AM #72Member

- Join Date

- Nov 2015

- Location

- Waikato

- Posts

- 744

Thanks John, Yes I can blow through it. The tubing I have ordered i think will present more problems as it is only 300mm so I can see a join coming with wont be easy.

Will keep looking for some longer thinner tube

-

19-01-2021, 08:06 PM #73Member

- Join Date

- Jul 2012

- Location

- Tauranga

- Posts

- 2,637

Those copper tube water cooled contraptions are sooo last year

https://youtu.be/YbcZFDYERic

-

19-01-2021, 08:14 PM #74Member

- Join Date

- Jul 2012

- Location

- Tauranga

- Posts

- 2,637

I will have some 750"F templaq turning up next week for those guys that wanted it.

Ideally 4 people would be grate then I havent lost any money!

So far I have @Mick Hunter @Morepork @kristopher

Anyone else $25 plus postage? first person to reply on here can be the 4th.

-

19-01-2021, 09:14 PM #75Member

- Join Date

- Jul 2012

- Location

- Invervegas

- Posts

- 5,663

I'll go with it thanks John. Please let me know the payment details. Cheers

Similar Threads

-

DIY Inductive Annealer

By Puffin in forum Reloading and BallisticsReplies: 17Last Post: 18-09-2017, 01:07 PM -

A few spare minutes this afternoon. Induction Annealing

By mikee in forum Projects and Home BuildsReplies: 11Last Post: 05-05-2016, 08:41 AM -

Best Case Annealer

By 7mmsaum in forum Reloading and BallisticsReplies: 13Last Post: 07-09-2012, 05:09 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

95Likes

95Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks