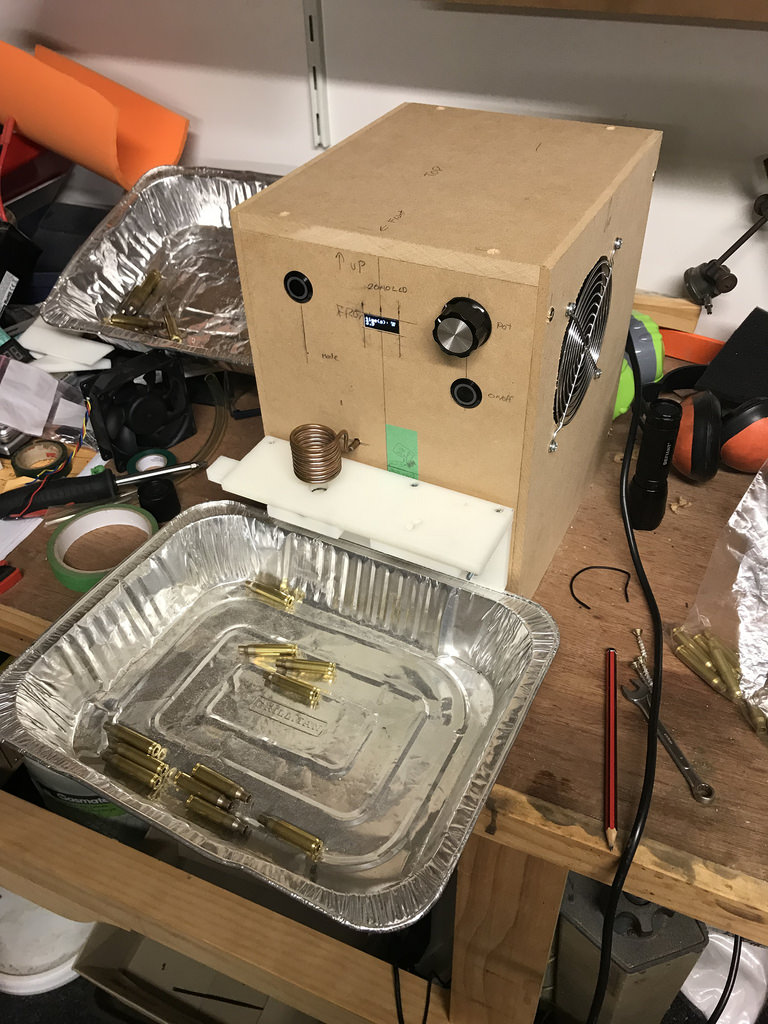

it's rough looking but works good. video of it in action at the bottom.

Video In Action

pretty much used this guys design for the induction part, but used a different controller and got all my parts off Aliexpress.

Induction brass annealer | Shooters' Forum

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 97

Thread: DIY Induction Annealer

-

16-04-2018, 09:33 PM #1Member

- Join Date

- Nov 2016

- Location

- Orewa

- Posts

- 86

DIY Induction Annealer

-

-

17-04-2018, 11:42 AM #2Member

- Join Date

- Dec 2012

- Location

- Wellington

- Posts

- 1,786

I tried to get a burner one going and while the electronics worked great the mechanical feeding was flaky. I have wondered about using a case collator dropping into something like this with a trapdoor to drop it into water.

"I do not wish to be a pawn or canon fodder on the whims of MY Government"

-

17-04-2018, 11:45 AM #3

-

17-04-2018, 11:48 AM #4

I (well my brother actually) built an annealer that uses 2 propane? torches. I must get a video of it running. I wanted to build an induction annealer but it all seemed to hard (and expensive) but this has renewed my enthusiasm to have a go

Sent from my SM-N950F using TapatalkIf it's not a first round hit you need to practice more

-

17-04-2018, 07:14 PM #5Member

- Join Date

- Nov 2016

- Location

- Orewa

- Posts

- 86

-

17-04-2018, 07:34 PM #6

-

23-04-2018, 09:59 PM #7Member

- Join Date

- Nov 2016

- Location

- Orewa

- Posts

- 86

If anyone's interested, got the timing dialed in for 223, 308, 270 & 300WM. Yellow is 650F and white is 450F.

-

24-04-2018, 12:03 AM #8

Hi @MGNZ this is definitely interesting! Source code yes please and do you have some photos of the beast open? Parts list?

Awesome and Thanks in advance

300

-

24-04-2018, 11:20 AM #9

-

24-04-2018, 11:48 AM #10

-

24-04-2018, 11:52 AM #11

-

24-04-2018, 08:51 PM #12Member

- Join Date

- Nov 2016

- Location

- Orewa

- Posts

- 86

Hi @300CALMAN,

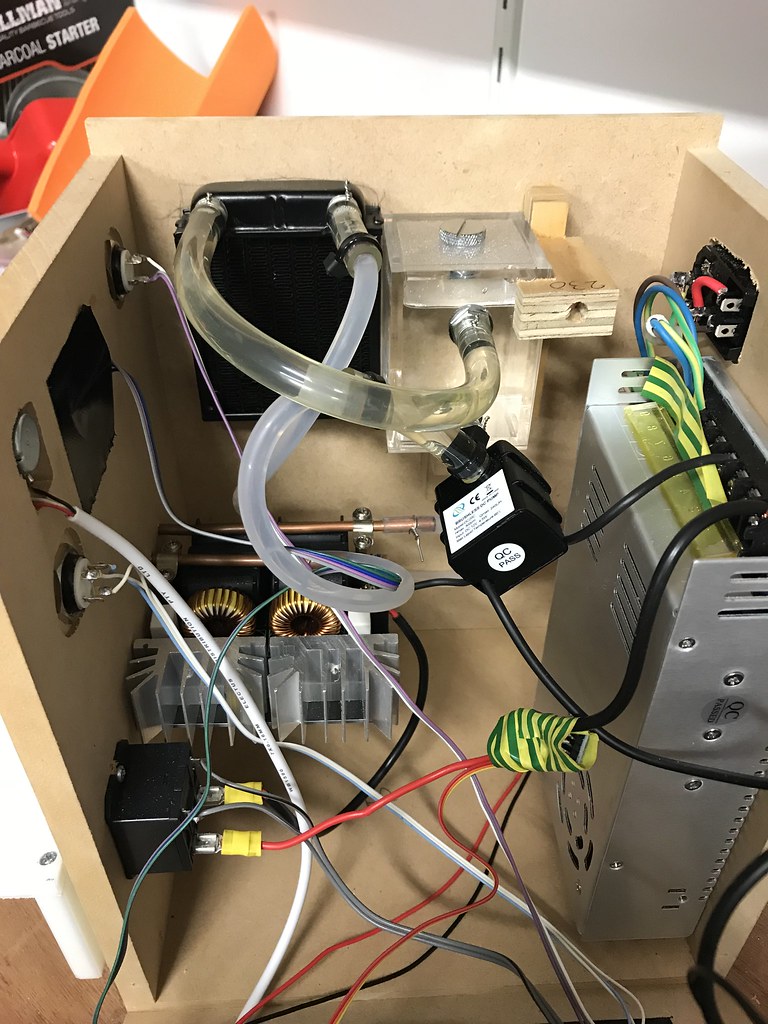

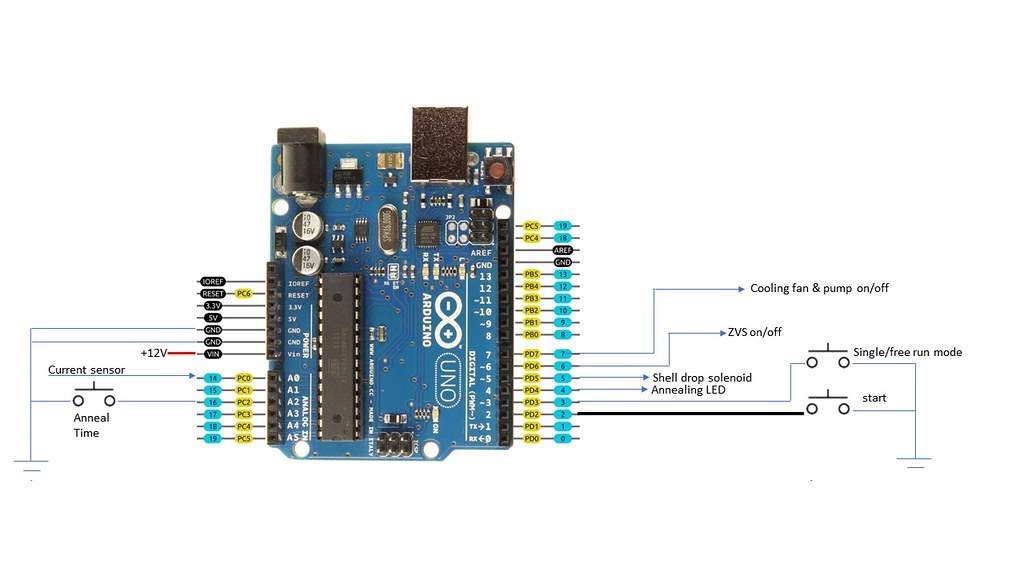

some pics below of the inside and arduino pinout and also some links to the bits from aliexpress and the software source.

ZVS induction board

Display

12V 2A power supply

Cooling pump

water tube

1/8" copper tube

48V 600W power supply

current sensor (optional)

Radiator

cooling tank

controller

arduino software source code

Last edited by MGNZ; 24-04-2018 at 09:01 PM.

-

25-04-2018, 05:56 AM #13

Wow that's hiding a water cooler and all! Very impressive

-

01-05-2018, 08:20 PM #14Member

- Join Date

- Nov 2016

- Location

- Orewa

- Posts

- 86

This project is pretty much finished now. video below of doing some 270 brass in free run mode.

I did 75pc of 223 brass without pausing - the coil remains cool and the only parts that were slightly warm were the resonant capacitors on the induction board.

** if anyone is going to build one of these - The water cooled coil is an absolute must. makes such a big difference to heat as well as efficiency

Cheers,

Mark

Free run video

-

01-05-2018, 09:27 PM #15

That is awesome. @40mm a big one for 40 mm?

Similar Threads

-

DIY Inductive Annealer

By Puffin in forum Reloading and BallisticsReplies: 17Last Post: 18-09-2017, 01:07 PM -

A few spare minutes this afternoon. Induction Annealing

By mikee in forum Projects and Home BuildsReplies: 11Last Post: 05-05-2016, 08:41 AM -

Best Case Annealer

By 7mmsaum in forum Reloading and BallisticsReplies: 13Last Post: 07-09-2012, 05:09 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

95Likes

95Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks