I managed to get the 2 halves apart with the use of some ice block sticks. Basically just slide/knock them in like wee wedges.

It's quite a relief when the mould finally cracks open without breaking anything!

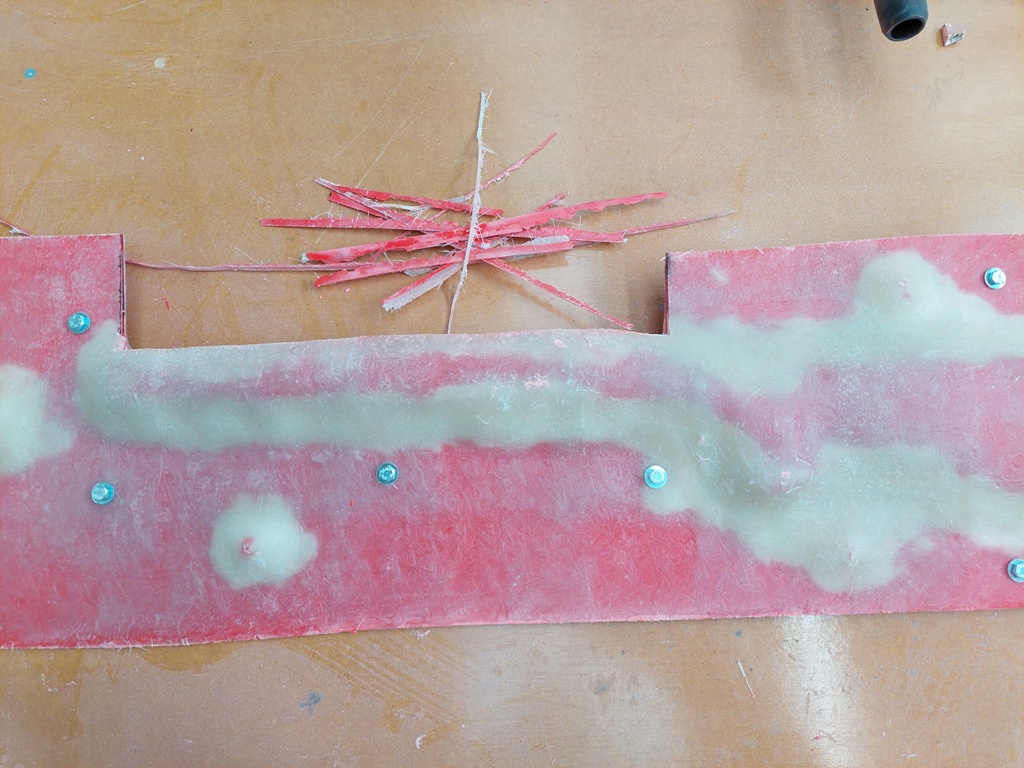

With the nice new mould I then took to it with the cutting disk on the grinder. This was to square up the edges and expose the action area. The exposed action area idea of mould making I got from @stug

Mould got cleaned up with hot soapy water then another 6 coats of release wax to each side before letting it sit overnight.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 33

Hybrid View

-

01-09-2021, 12:19 AM #1Those who live in glass houses, shouldn't piss off Geologists.

Similar Threads

-

Carbon fibre stock options for Howa Mini Action

By noboots in forum Firearms, Optics and AccessoriesReplies: 54Last Post: 05-04-2021, 10:35 PM -

Project Howa mini carbon chassis

By Remmodel7 in forum Projects and Home BuildsReplies: 35Last Post: 03-11-2020, 09:21 AM -

After market Stock for Howa Mini Action?

By GWH in forum Firearms, Optics and AccessoriesReplies: 32Last Post: 10-10-2019, 08:36 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

82Likes

82Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks