For quite a while Iíve wanted to make a lightweight 223.

With budgets never extending to a beautiful stock from one of the carbon stock guruís like the late Ken.

Iíve had a lot to do with composites through boat building and a common product has always tweaked my interest. PET foam core. Itís what high speed racing yachts are made from and forms a core in many composite constructions. It shapes easily and is incredibly light. The joy is that it shapes very easily with 40grit sandpaper yet is super strong.

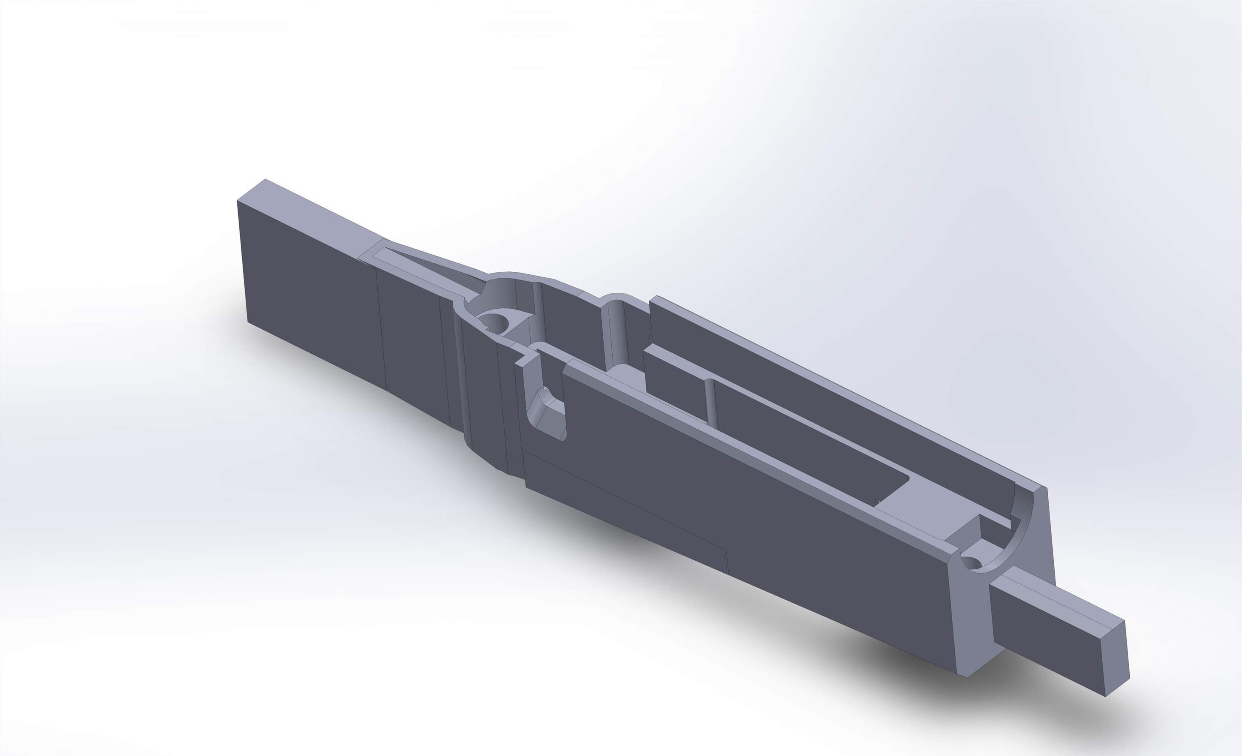

One reservation however was always how to do the inletting? This is where I was excited to stumble across https://www.vtp.co.nz/

A quick call and VTP was printing a core for a Howa mini. Amazing service too!

Hereís a couple of progress shots. I intend to do the first one in fiberglass to see how it goes, then Iíll switch to carbon for the next.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 30

Thread: Lightweight 223 project

-

30-06-2022, 06:53 PM #1Member

- Join Date

- May 2012

- Location

- Kaukapakapa

- Posts

- 975

Lightweight 223 project

-

-

30-06-2022, 06:56 PM #2#DANNYCENT

-

30-06-2022, 06:59 PM #3Member

- Join Date

- May 2012

- Location

- Kaukapakapa

- Posts

- 975

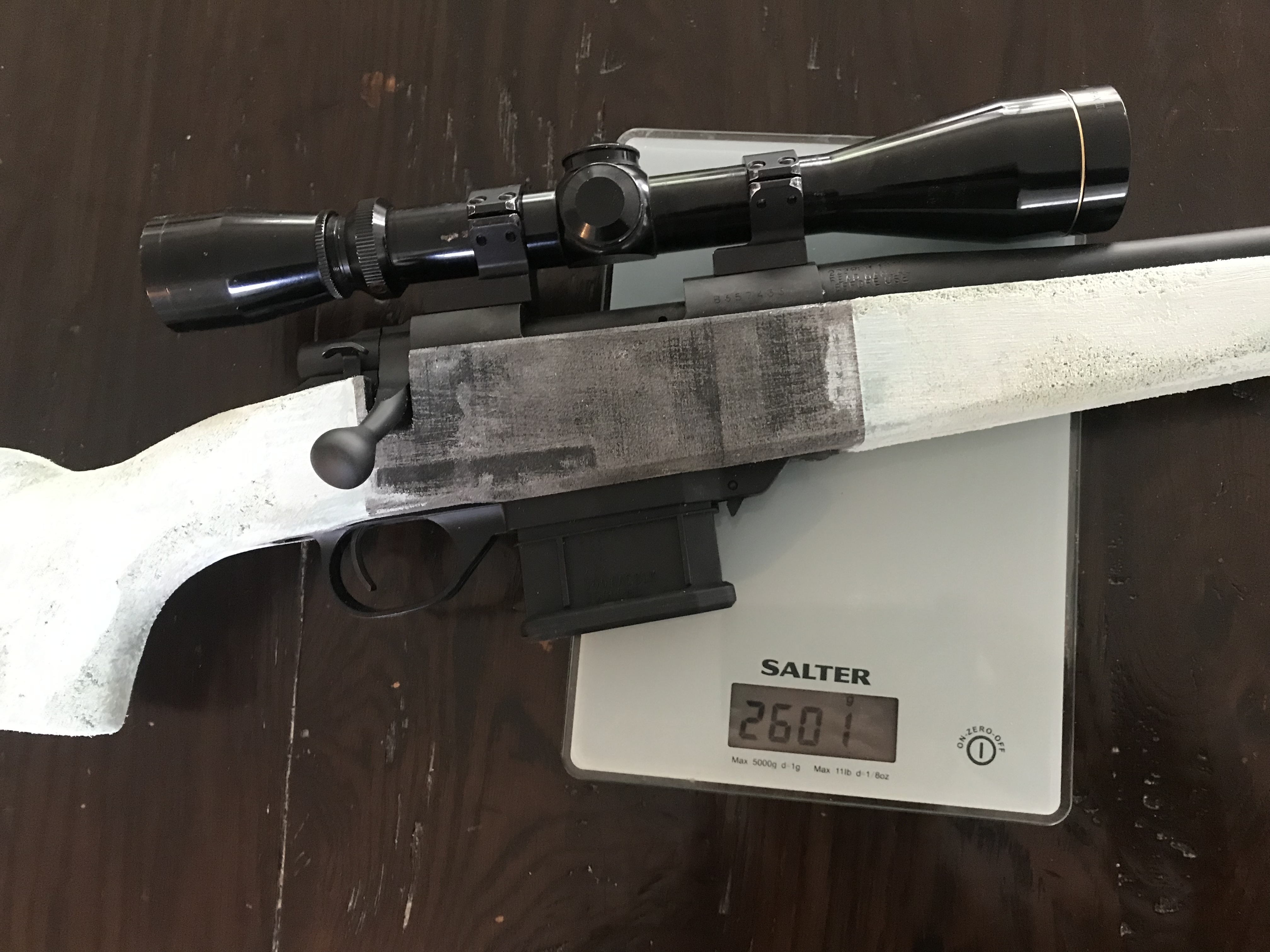

Weight includes suppressor but hasn’t been glassed yet. That’s the next step

-

01-07-2022, 09:24 AM #4Member

- Join Date

- Mar 2018

- Location

- Darfield

- Posts

- 435

Cool project, will be watching with interest.

I've been wanting to do something similar, I was thinking to try vacuum bag the glass on but not sure how it would go with all the curves. Where do you source your PET foam from?

-

01-07-2022, 05:57 PM #5

Thats an awesome idea to use the 3d printed inletting block, the howa minis are perfect for this type of project.

I have thought about doing a similar thing but using super high density closed cell foam for the inletting area, but undercut from the action a reasonable amount (5-6mm) with lighweight foam for the forend and stock like you have done, then sheath the whole thing in carbon and use a milled fiber/silica filled epoxy to bed the action.

Why not go straight to carbon for the first one? Cloth for a project like this would only be $50-60 tops.

What is your plan for laminating? I have tried wet laminating stocks in the past with no vacuum and it is very tricky to get good consolidation around the tight corners. If I were to try it again, I would certainly use vacuum.

Ill be watching your project with interest.

-

01-07-2022, 08:46 PM #6Member

- Join Date

- May 2012

- Location

- Kaukapakapa

- Posts

- 975

Hey @SixtyTen

Thanks for the interest.

Although I agree that you could do this with inletting a foam/resin core, the joy of a 3D print is that it is accurate, stable and very light weight.

Fiberglass I’m interested in using as it’s easier to layup and I can add layers in areas that need it and leave it thin where it’s not required. A multiple layer 2oz and 1oz laminate using epoxy will be super strong. Easily strong enough for my needs.

It’s fast to get the foam shaped and the 3d core is inexpensive so I plan to try a couple of different ways of making it.

I hope this gives others ideas to try the same

If any Auckland members want PET foam core I have quite a bit left as you have to buy a full sheet at a minimum.

-

01-07-2022, 09:13 PM #7

Very clever and cool stuff, great innovation. Keep the updates coming pls.

Just...say...the...word

Just...say...the...word

-

03-07-2022, 12:42 PM #8Member

- Join Date

- May 2012

- Location

- Kaukapakapa

- Posts

- 975

Little update here, it’s glassed , phew!

And with a sand and a spray of primer, it’s ready to fill pin holes

380g which I’m pretty stoked with.

Jandal recoil pad to come

-

03-07-2022, 02:22 PM #9

Looking good, did you use a mould at all or is it just shaped by hand and simply layed on ? Did you use vac bag ? Much nicer looking fore than the factory stock.

#DANNYCENT

-

03-07-2022, 02:52 PM #10Member

- Join Date

- May 2012

- Location

- Kaukapakapa

- Posts

- 975

Thanks @dannyb

Cut with bandsaw,Shaped by hand with sureform and 40grit, but templated off a model 7 stock I had.

No mould, no vac bag, just hand laid.

-

03-07-2022, 11:11 PM #11Member

- Join Date

- May 2012

- Location

- Kaukapakapa

- Posts

- 975

2kg

-

03-07-2022, 11:14 PM #12

shit hot that's just about rough enough for me to have a crack

can you post a bit of a step by step of what you did and what products you used ?

I have an idea of the shape stock I want to use and will get hopping on collecting the other bits needed.

are you concerned it could snap where the foam core is bonded to the printed inlet ?

can't wait to have a crack at this #DANNYCENT

#DANNYCENT

-

03-07-2022, 11:28 PM #13Member

- Join Date

- May 2012

- Location

- Kaukapakapa

- Posts

- 975

@dannyb, I’m happy to have a yarn on the phone if you are going to have a go.

I don’t think the connection point will be at risk at all. It’s joint with internal tabs into the foam on the inside and fully glassed in on the outside. I’d be much more concerned of it cracking through the pistol grip. I added quite a bit more glass in this area but still think it could happen if I fell on it.

-

05-07-2022, 09:16 PM #14

interested in how you group with it...Ive found with my superlight crude stock I really have to concentrate on holding rifle firmly as apposed to getting away with murder as did beforehand.

75/15/10 black powder matters

-

05-07-2022, 10:11 PM #15Member

- Join Date

- Aug 2012

- Location

- helensville nz

- Posts

- 4,696

yeah i shoot @Freezer's rifles a bit doing load development and also checking zero if he is unable to make time (busy boy)

his 270 feels like a toy to me with its stug carbon stock its only 3.4kg

I'm used to verry heavy rifles my main hunting rifle is well over 5kg (heavy barrel howa with walnut stock)

i find it a challenge to shoot the light rifles but have worked out that you cant baby them like you do with a heavy rifle

i hold my personal rifle very lightly but with the 270 of freezers you really have to hold onto it and pull back into your shoulder to get it to shoot well really properly be in control almost man handle it

its going to be a real challenge with this 223 currently only 2.7 with scope and can being a 223 will help but its still going to be "fun"

Similar Threads

-

Wet day project

By craigc in forum The MagazineReplies: 4Last Post: 24-02-2019, 09:34 PM -

the new project

By northdude in forum Firearms, Optics and AccessoriesReplies: 8Last Post: 27-03-2016, 12:50 PM -

New Project

By Freezer in forum Projects and Home BuildsReplies: 32Last Post: 25-09-2012, 06:39 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

93Likes

93Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks