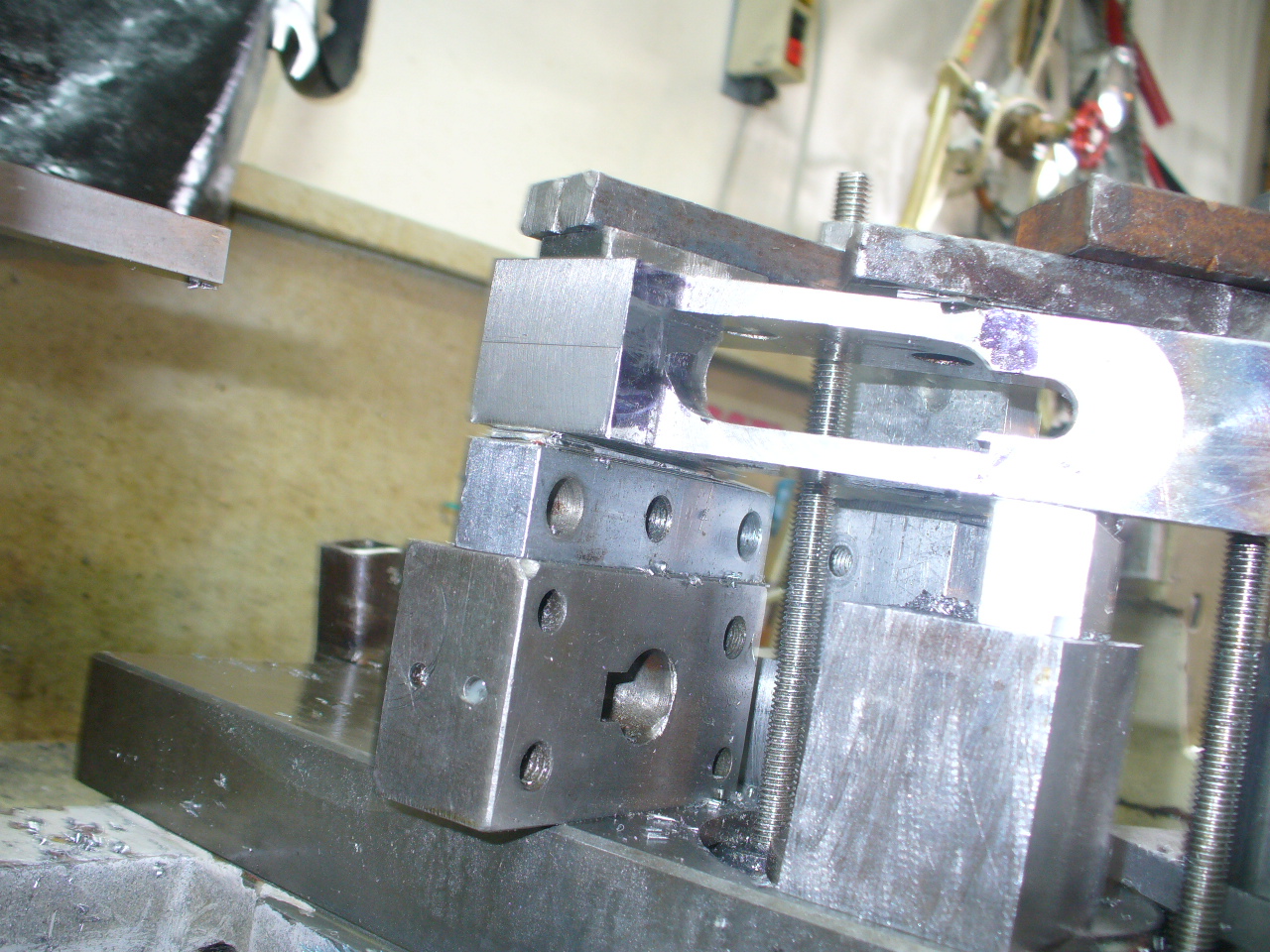

The first mill cut out .650" slot and I needed .735" per the plans, so after a reset up to get it lined up on centre I mounted a broken mill cutter with only one cutting flute. Set in the four jaw chuck I can offset it to fly cut out to the right size, just adjust the jaws a bit to set the cutter out a bit more till the slot is at the right size, stopped at .734" so I can give it a bit of a polish. Yes there is a bit of slop in the cross slide, so spring helps and small cuts, one off my coming up projects, a new nut, have some torbin bronze and ali bronze for it and as I need the cross slide to do this will have to do some careful measuring to thread the nut. May make it like a clasp nut so I can adjust it for wear.

, I didn't break it, bought a box of used one`s on TRD/me, some are good and very handy.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 91 to 105 of 106

-

03-07-2020, 05:50 PM #91

-

-

09-07-2020, 08:27 PM #92

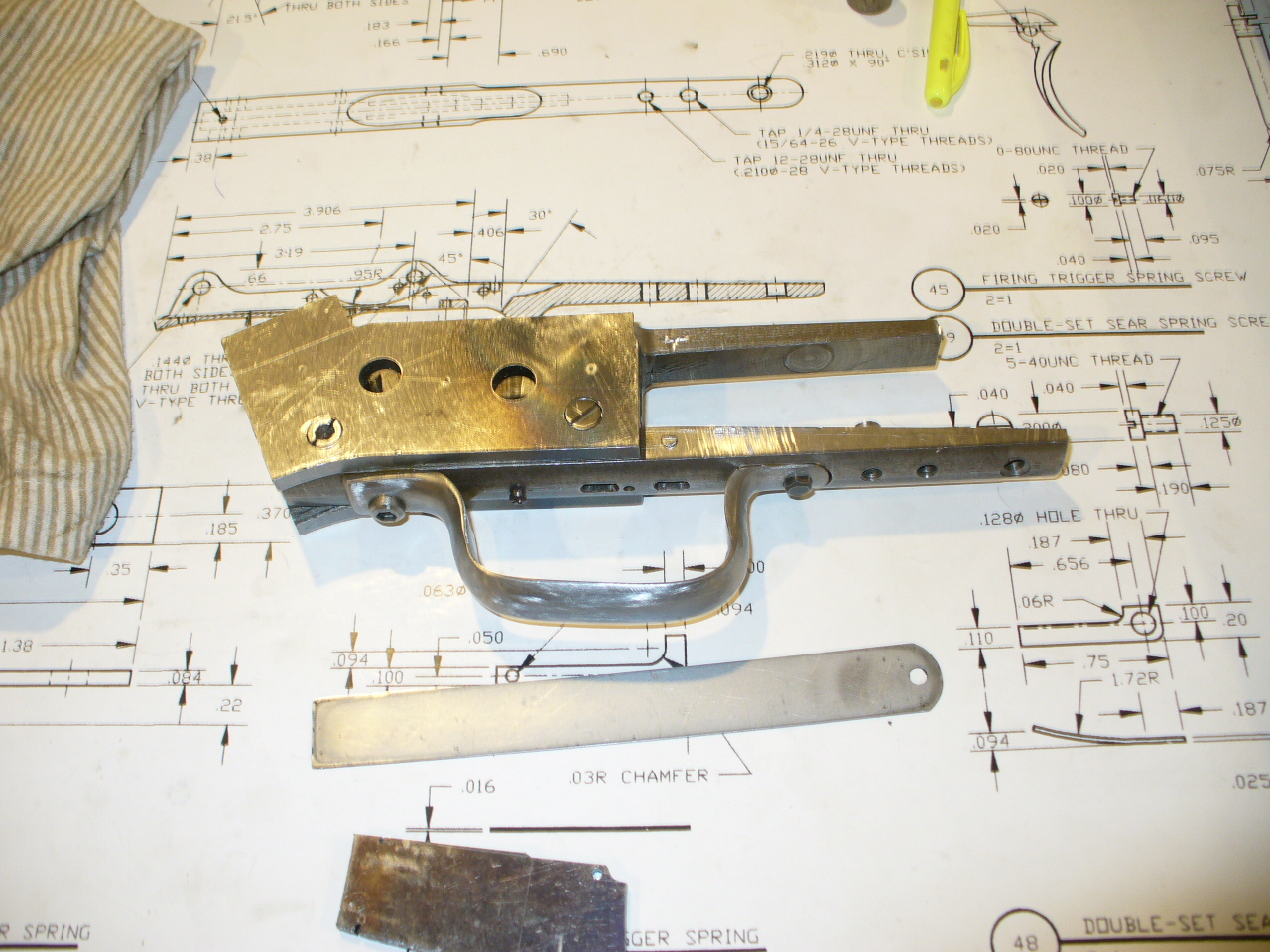

Still in milling mode, have changed the cutter for a rounded tip one so puts a corner Radis to help stop cracking. This is now milled out to size ready for the hammer and breach block so may have look at carving them out from a lump of 4140 I had left over from the Sharps build. Still a lot of work on the action yet, watch this space,

, could be a few years before it goes bang.

, could be a few years before it goes bang.

, Coming on slowly.

, Coming on slowly.

-

10-07-2020, 09:04 PM #93

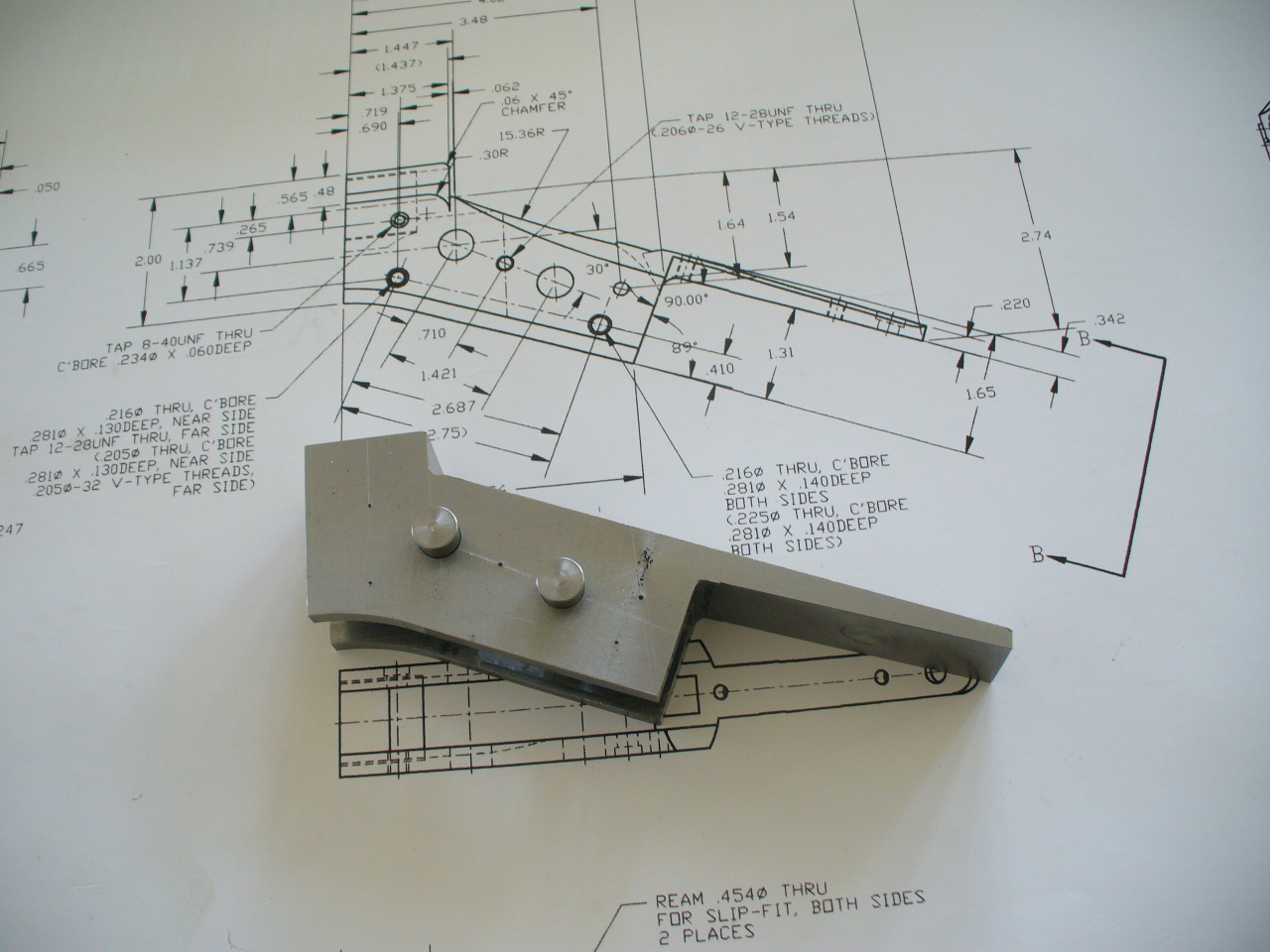

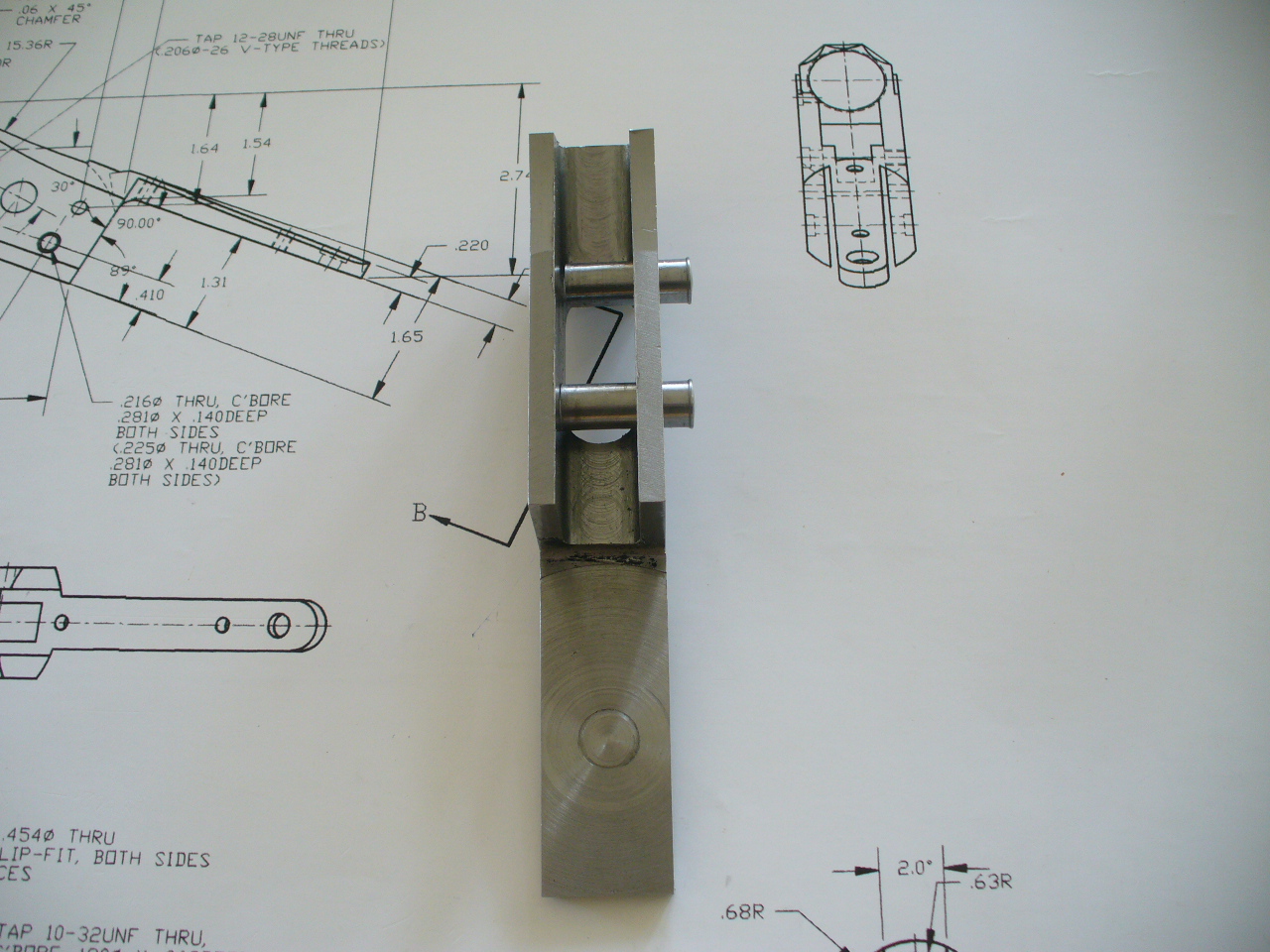

So with that part milled out it`s really starting to look like it will do the job. Fear bit of work to do yet but it`s coming a long, here`s what it looks like so far and the pins are a snug fit so I`m happy with that.

, What can I say.

, What can I say.

, Pins are a tap out fit,

, Pins are a tap out fit,

-

10-07-2020, 09:26 PM #94

-

22-07-2020, 05:47 PM #95

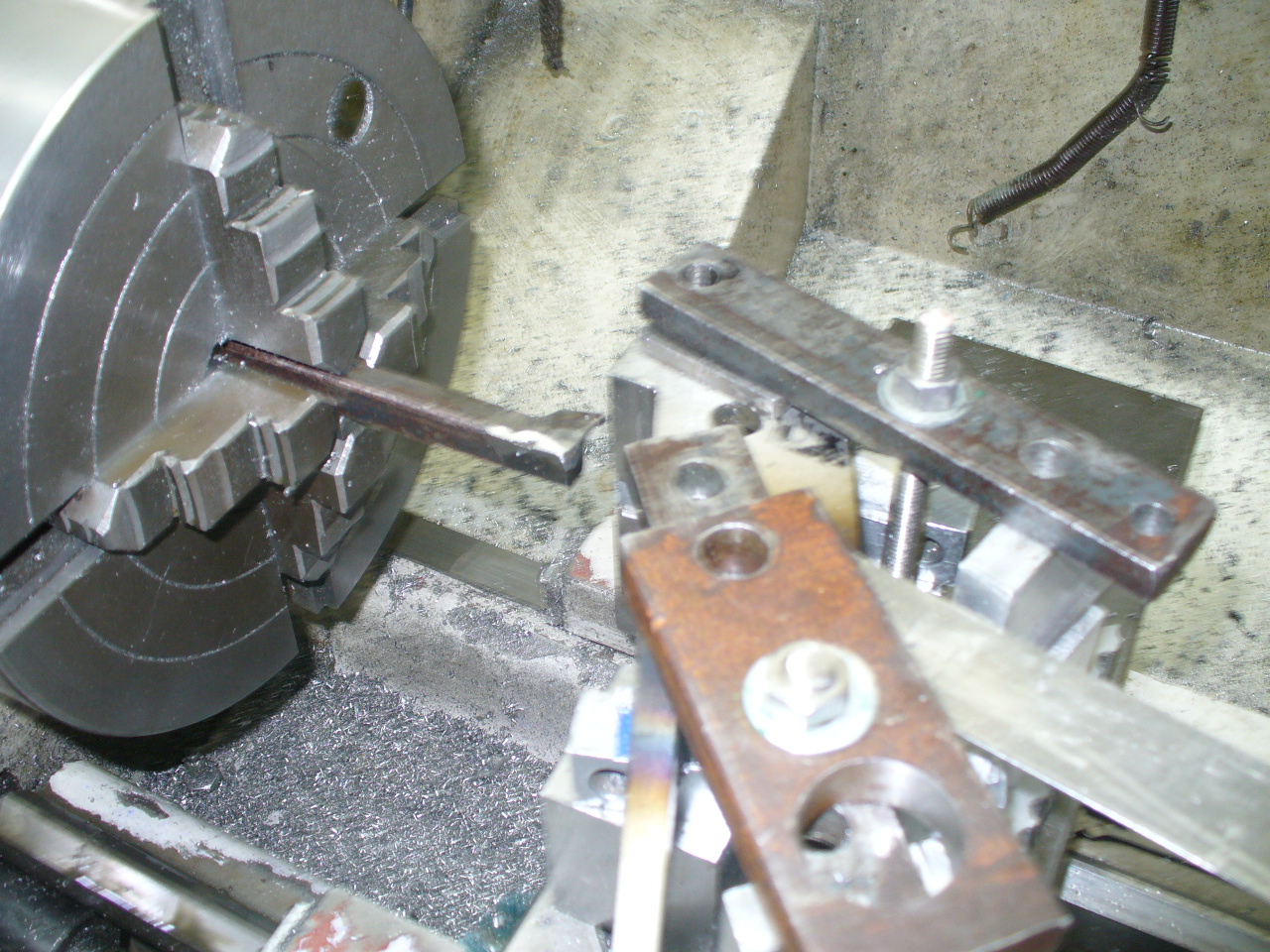

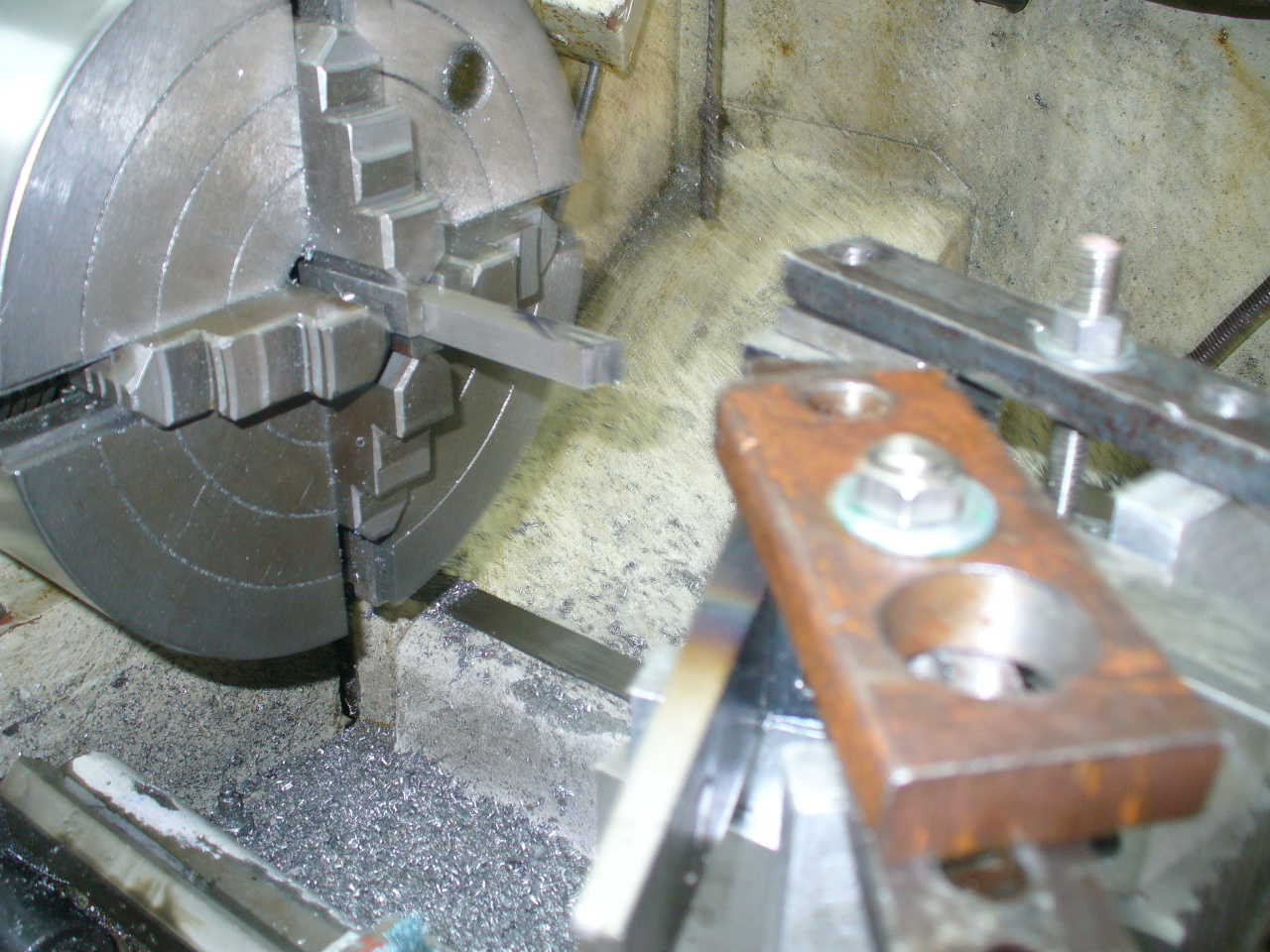

OK, so having milled out all the centre it needs to be square in the round corners, this was achieved by using a T/C tipped cutter from a saw blade first and then a small HSS square one to finish. Mounted in the four jaw chuck and set at the right height the lathe saddle is moved back and forward like a shaper, with small infeed on cross slide got the job done.

, T/C tipped blade cutter first.

, T/C tipped blade cutter first.

, square one to finish.

, square one to finish.

-

23-07-2020, 05:16 PM #96

Jeez your a clever bugger. Its amazing what you can get that lathe to do. Nice simple solutions too.

-

27-07-2020, 08:47 PM #97

Yes I can get it to do most things, here`s one, It helps with my beer supplies,

as I use shims to pack things up I have found that ali beer cans cut into strips are the best for this. Different brands of beer come in cans of different wall thickness and have let my wife know that I must have them for my hobby, but you will have to empty them first she said, I know, its a hard job but I know I "CAN" do it.

as I use shims to pack things up I have found that ali beer cans cut into strips are the best for this. Different brands of beer come in cans of different wall thickness and have let my wife know that I must have them for my hobby, but you will have to empty them first she said, I know, its a hard job but I know I "CAN" do it.

-

28-07-2020, 06:58 PM #98Member

- Join Date

- Jan 2019

- Location

- South Canterbury

- Posts

- 1,649

-

30-09-2020, 08:16 AM #99Member

- Join Date

- Jan 2019

- Location

- South Canterbury

- Posts

- 1,649

http://www.youtube.com/shorts/Aag-GvhxEwA

Just saw this and thought a few would find it interesting.

-

10-09-2021, 08:28 PM #100

Well guys this bloody lock down bit is a bugger wearing out my shoes walking the dog , getting wood to keep the fire going. My lathe has packed a sad, broken gear in gear box so using it by hand. Yep still working on my project and a few others to keep busy , so its coming along with my back yard way. I have made a barrel for it , just have to chamber it. Pic`s so far.

Similar Threads

-

Making a Sharps Barrel in my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 273Last Post: 08-03-2021, 05:22 PM -

Rolling block

By rusl in forum Firearms, Optics and AccessoriesReplies: 26Last Post: 04-08-2019, 03:07 PM -

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

189Likes

189Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks