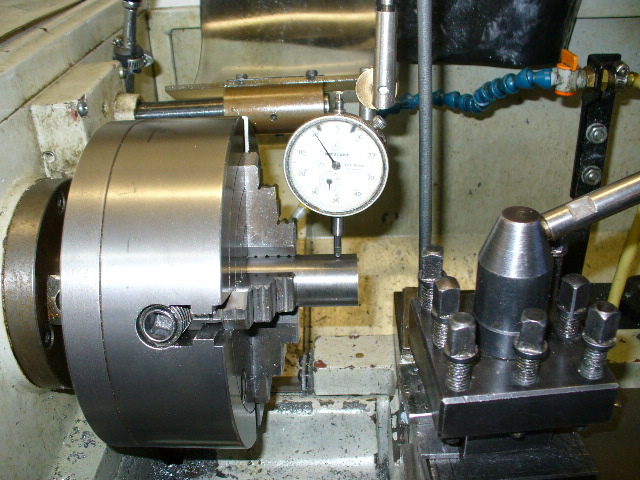

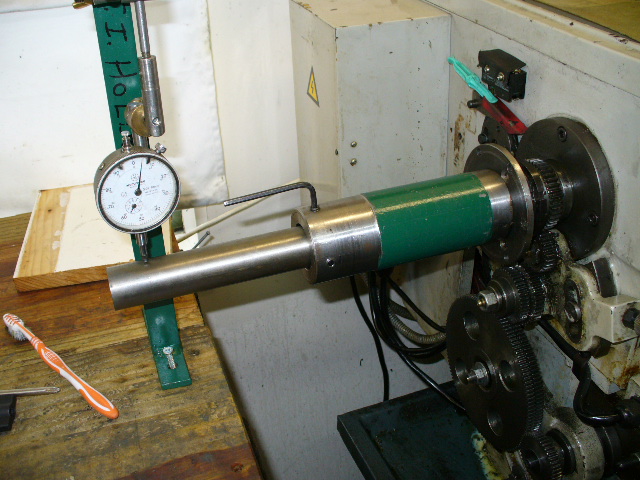

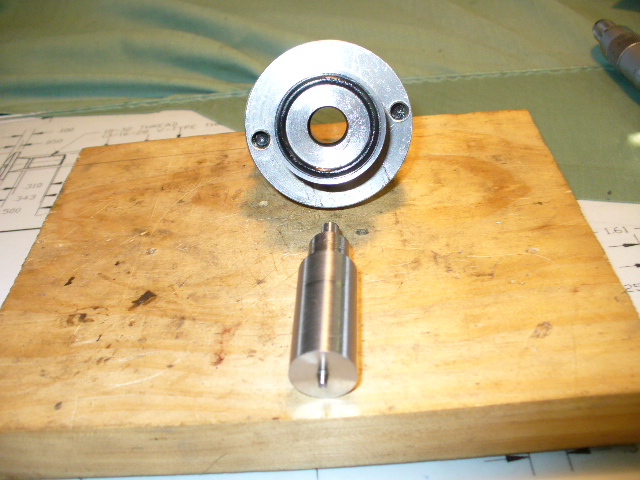

Hi All, This is how I drilled, reamed and cut rifle a barrel in my lathe. My lathe is belt driven and .900" centres ,I made some attachments to fit on the lathe so I could do this, never thinking it would work but having a go any way. I made up a barrel centring tube to screw on to a bit of thread at the back of my lathe, with fore grub screws to centre the barrel. It also has a round flange welded on with six spaced holes for the rifling register .pic`s, Homebrew.357.

[

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 274

-

28-09-2014, 08:51 PM #1

Making a Sharps Barrel in my lathe.

-

-

28-09-2014, 10:35 PM #2

You made your own barrel? I'm very impressed, and jealous of your skill!

Using Tapatalk

-

29-09-2014, 02:04 PM #3

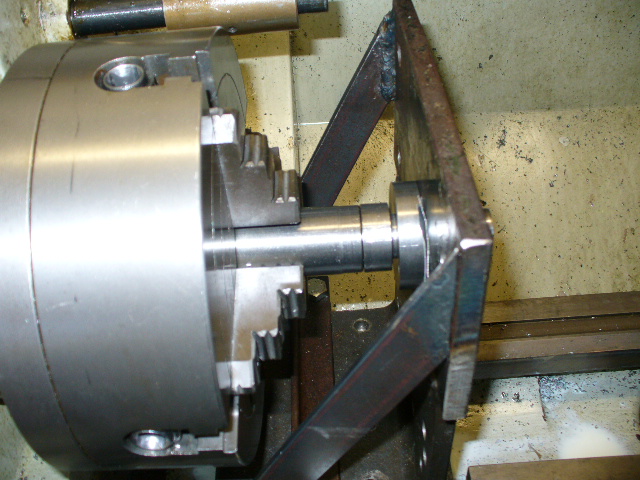

Hi Res, I`m drilling this barrel now, about 16" to go and no It`s not my first one, check my other threads. The barrel stock is trued up in the lathe at each end and a fine cut and faced for register. You can see the tail end attachment in place to holed the barrel and screws for trueing up, pic`s,

, Homebrew.357.

, Homebrew.357.

-

29-09-2014, 06:01 PM #4Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,180

well bugger me with a pineapple and call me herman -what will ya come up with next.

listen got a wee challenge - there a political mob lookin for a leader -apparently if the latest sideshow had of been a horse race -theyd have been hard pressed to beat sunset past the post. could you manufacture something to take charge of em, whats available aint doin the job.

-

29-09-2014, 08:45 PM #5

Yer, your right Kotuku, they are like a bloody rugby scrum, all falling all over then selfs , could put some gun powder in

some where and lite it, mite get a bang.

some where and lite it, mite get a bang.

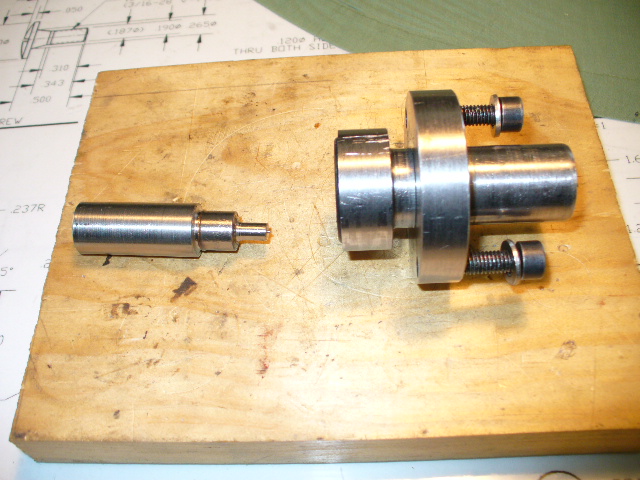

The gun drill guide is made in three bits, guide stub, drill guide, and holder. The holder has two screws for fitting and the drill guide is a taper press fit in, will not move. the guide stub is for lining it all up in the fore jaw chuck true to the lathe centre, will show the setup later. , HOMEBREW.357.

, HOMEBREW.357.

-

29-09-2014, 08:56 PM #6

What mates up with that O-ring? Something to do with keeping coolant or cutting lube in somewhere? Bloody cool stuff, really liked all your sprockets etc set up on the lathe for your last barrel. buggered if I know how you worked out your sprocket ratios to come up with a twist rate...

10MRT shooters do it 60 times, in two directions and at two speeds.

10MRT shooters do it 60 times, in two directions and at two speeds.

-

29-09-2014, 10:56 PM #7Member

- Join Date

- Jun 2014

- Location

- Middle Earth

- Posts

- 231

I work on the tools, very impressive I like your work.

-

30-09-2014, 11:39 AM #8Member

- Join Date

- Nov 2012

- Location

- AKL

- Posts

- 396

more pics! Cool!!!

-

01-10-2014, 07:38 PM #9

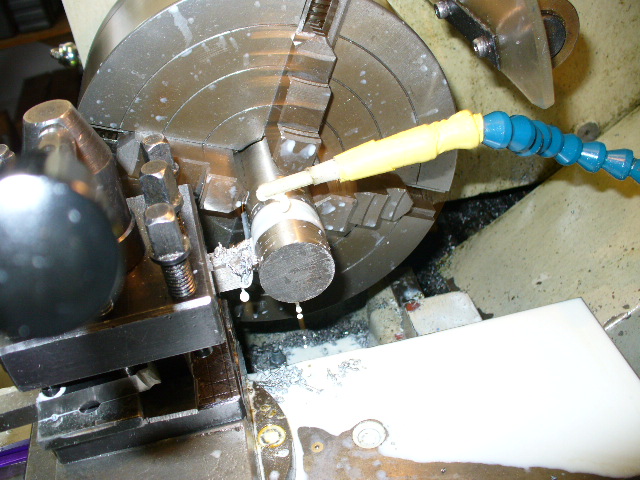

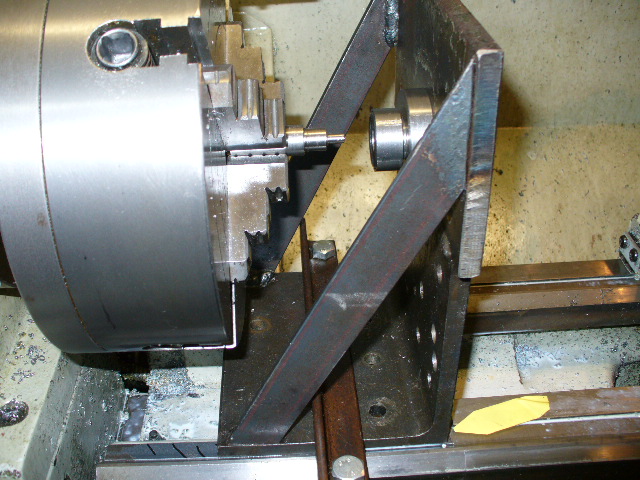

Ok, The drill guide is mounted on my angle bracket and it sits in front of the 4 jaw chuck, but first the guide stub in set in the chuck true. The drill guide and bracket is set in front of the chuck with the stub in the guide and clamped . Guide is lined up on the stub and the two screws of the housing are set tight, now the drill guide is lined up on centre and locked on the angle bracket. The stub and angle bracket are removed and the barrel stock is set up in the lathe and the angle bracket is clamped back in front all lined up, and the seal stops the oil dribbles . Photo shoot,

Ok, The drill guide is mounted on my angle bracket and it sits in front of the 4 jaw chuck, but first the guide stub in set in the chuck true. The drill guide and bracket is set in front of the chuck with the stub in the guide and clamped . Guide is lined up on the stub and the two screws of the housing are set tight, now the drill guide is lined up on centre and locked on the angle bracket. The stub and angle bracket are removed and the barrel stock is set up in the lathe and the angle bracket is clamped back in front all lined up, and the seal stops the oil dribbles . Photo shoot,  , Homebrew.357.

, Homebrew.357.

-

01-10-2014, 07:44 PM #10

Lovin your work dude, honestly my skills extend to building a plumb bob in the lathe at the local walls tech in the 80's and that's about it... Well Done that man!

-

04-10-2014, 07:47 PM #11

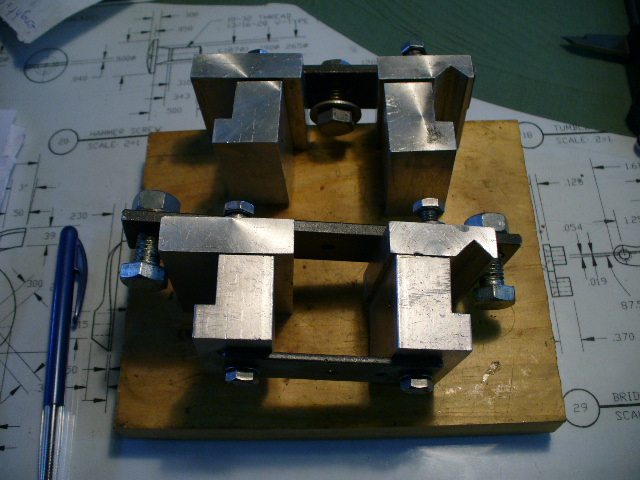

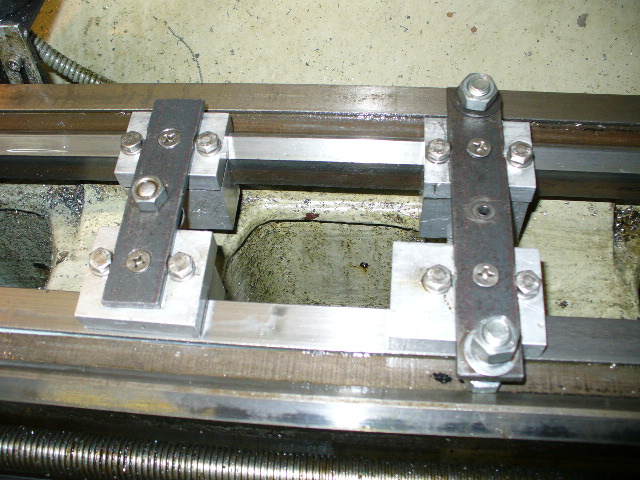

Well hi there C Diem, I`v got two foots in them there hills as well, just a jafa. Ok, to get things moving on my lathe bed ways and to hold the gun drill, I made up to sets of ali blocks that fitted on to the bed ways, on top of theses I mounted my X/Y vice and the gun drill was clamped in at lathe centre height. The blocks and vice is pulled along by the lathe saddle vie a bracket under the saddle , up turned bit is in the front of the saddle and is held in place by the following steady, the back is bolted in front of the vice, (arrows show it) in the pic`s.

. Homebrew.357.

. Homebrew.357.

-

05-10-2014, 07:48 PM #12

-

07-10-2014, 07:49 PM #13

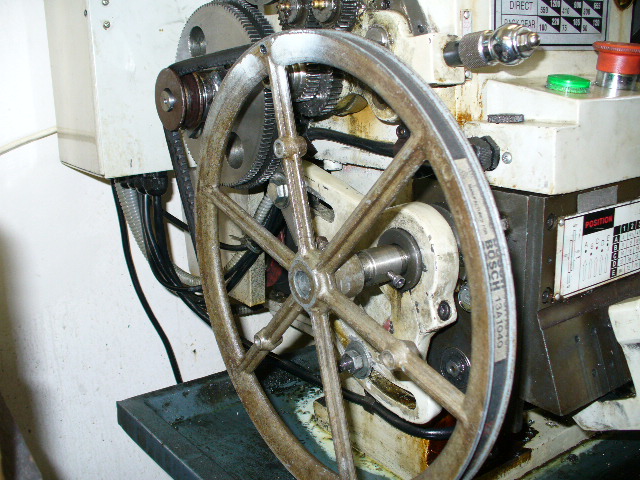

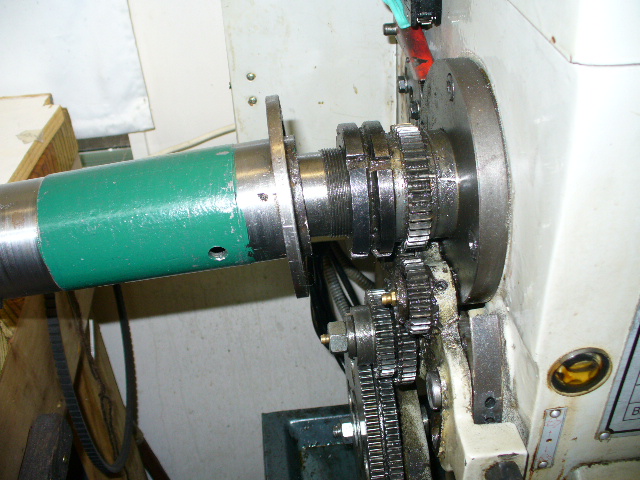

Hi, Now that I had things set up for drilling with the gun drill ready to go, had to think about the in feed rate. The drill must go in very slowly for small chips that can be flushed out with the cutting oil and my lathe, (and most other ones)the finest feed is to fast. So with some junk bits I set about down gearing it. A large gear, 127 tooth, was driven with a forty tooth one, the first drive, I swopped it for a thirty tooth one. This large gear had fore holes ,so using two I made up two ali plugs and a bracket to fit on it. From my junk box I got two Vbelt pulleys, a small one and a large one from a old washing machine . The small one was fitted onto the bracket at centre so it would drive the big one and the big vbelt pulley was fitted onto the lathe gear box in drive. An extension arm was made to hold the large gear so it could get drive from the thirty tooth gear and also tension the vbelt. Now with the lathe gear box set at the finest feed I got five turns of the chuck for 0.010 mm in feed WITH THE D T I ,

I diden`t believe it, so checked again, YEP, ON THE MONEY. The pic`s, Hope this helps under stand it all, Homebrew.357.

I diden`t believe it, so checked again, YEP, ON THE MONEY. The pic`s, Hope this helps under stand it all, Homebrew.357.

-

07-10-2014, 07:58 PM #14

A few more pic`s.

, And all in place.

, And all in place.![Name: P1010092[1].JPG

Views: 2059

Size: 169.7 KB](https://www.nzhuntingandshooting.co.nz/attachments/f53/29831d1412664991-making-sharps-barrel-my-lathe-p1010092%5B1%5D.jpg)

![Name: P1010093[1].JPG

Views: 2084

Size: 151.6 KB](https://www.nzhuntingandshooting.co.nz/attachments/f53/29832d1412665032-making-sharps-barrel-my-lathe-p1010093%5B1%5D.jpg) , that's It.

, that's It.

-

07-10-2014, 08:03 PM #15

Wow that's a really low rate of feed! Is that what the drill makers recommend ?

Sent from my GT-S5360T using Tapatalk 2"Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

Similar Threads

-

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM -

Anyone got a lathe at home

By specweapon in forum Projects and Home BuildsReplies: 12Last Post: 14-07-2014, 09:55 PM -

Is there anyone in Dunedin that can drive a lathe?

By gimp in forum Firearms, Optics and AccessoriesReplies: 20Last Post: 19-02-2012, 06:34 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

419Likes

419Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks