Champion!

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 121 to 135 of 274

-

18-05-2015, 09:07 PM #121

-

-

18-05-2015, 09:27 PM #122

Hi, Have sent the block of 4140 steel for the receiver to cut out the breech block hole, should hear back soon when finished. Went to the black powder shoot and after lunch had a go with my Hawken, .45, well getting all ready to load and hammer to half cock, no spring load, the tumbler to spring pin had come out,

, so a frantic side plate out, pin back in and pliers to hook spring back on. Had my best group with ten shots, fore holes touching ,

, so a frantic side plate out, pin back in and pliers to hook spring back on. Had my best group with ten shots, fore holes touching , . The sight is finished and looks good, Homebrew.357.

. The sight is finished and looks good, Homebrew.357.

-

18-05-2015, 09:32 PM #123

Oops, forgot the pic`s,

,

,  ,

,  ,

,  , And the day went with a bang!, Homebrew.357.

, And the day went with a bang!, Homebrew.357.

-

18-05-2015, 09:43 PM #124

Gotta get my arse to one of these BP shoots, looks like a hoot!

-

19-05-2015, 01:02 PM #125

Hi, Its a lot of fun alright , will post some pic`s on a new thread. Here is my best group bench shooting with ten shots aiming at the black cross, 6 o'clock, mind fore shots are missing,

have to put a bigger backing paper to see where they go. Was trying out a new way to load, powder in 70grs 3f, card on powder, lube felt wad, S P G lube 270gr bullet. Seam's to like it, this will be my hunting load. Cheers, Homebrew.357.

have to put a bigger backing paper to see where they go. Was trying out a new way to load, powder in 70grs 3f, card on powder, lube felt wad, S P G lube 270gr bullet. Seam's to like it, this will be my hunting load. Cheers, Homebrew.357.

, That's definitely a dead deer!.

, That's definitely a dead deer!.

-

20-05-2015, 03:43 PM #126Bah, humbug !

- Join Date

- Nov 2013

- Location

- Auckland, until I can escape south....to Southland.

- Posts

- 1,696

Looking good

That's the Akld Deerstalkers range, at Riverhead ?He nui to ngaromanga, he iti to putanga.

You depart with mighty boasts, but you come back having done little.

Sounds like a typical hunting trip !

-

21-05-2015, 08:19 PM #127

Yep, that's the one, this was the first time out there for me after convalescing from my hip op, had to give my Hawken a feed. But something will always go wrong, set up to start loading, hammer to half cock and no spring presser, the retaining pin to the sear had come out. So a frantic side lock off, fined pin and re hook up mainspring. After all that It`s a wounder I could hit anything. All so shoot my old PH .308 and a Marlin .3030 , helps keep the eye in .Homebrew.357.

-

21-05-2015, 08:19 PM #128Member

- Join Date

- Apr 2014

- Posts

- 49

Hi , are you still set up to bore a blank if so would you consider boring any for others (me for starters ) I would like one for black powder in free cutting mild steel ( 12L14) .

-

22-05-2015, 09:30 PM #129

Hi Lefty 1, I can re setup to drill a bore size ,( one at .419/20" and one at ,444". The two gun drills I have. I use my lathe for normal work, all the add on bits come off. I have a 26' blank, rifled 1-33' in 1018 steel with a roughish bore, needs lapping that I don`t want. It`s the rifling that takes time, have to make up a new rifling cutter head for each bore, and I would not say a price until you see the barrel and all would be for black powder only. At this time can only do a left hand rifling twist off 1-33'" or 1-20" , most M/L are 1-48"/1-60", Cheers, Homebrew.357.

-

24-05-2015, 10:43 AM #130Member

- Join Date

- Apr 2014

- Posts

- 49

Hi , and Thanks for the reply , I do not have a gun drill but I have a sine bar rifling bench nearing completion which gives you a choice of left or right hand and almost any twist you want and easy to make ..

I really want a barrel 30 to 34 inches long the .444 would be ok but at 26 is too short .. I can ream the bore to suit my requirements .. I am making a flint lock

-

24-05-2015, 07:01 PM #131

Hi, I've pm you Lefty and that 1018 blank rifled barrel is 1-25/5 twist, .450" bore . Will be picking up my receiver block on monday with the hole for breech block done, so will be back in to it, Ceers . Homebrew.357.

-

25-05-2015, 08:49 PM #132

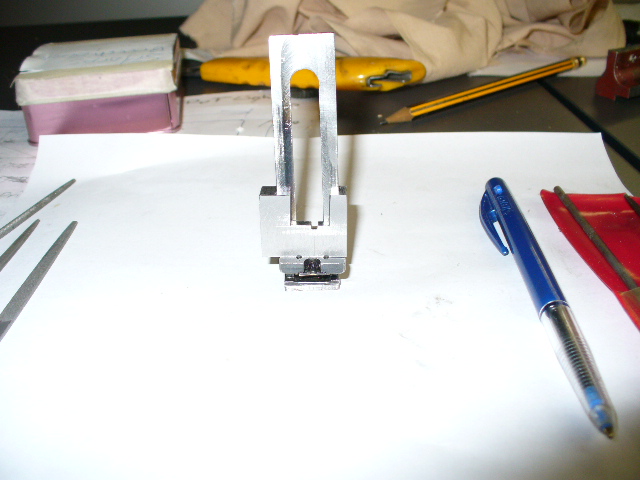

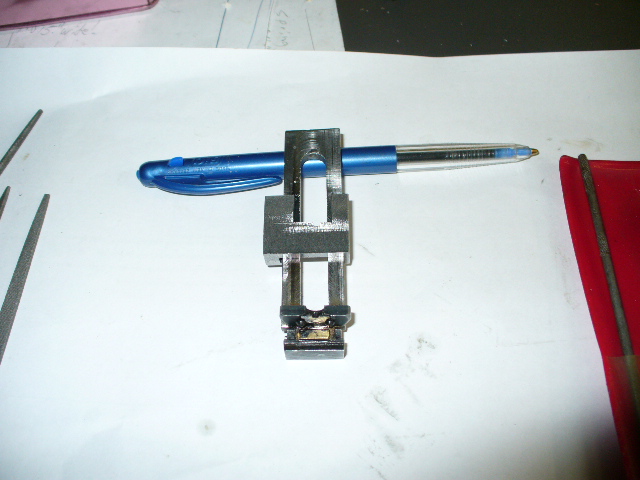

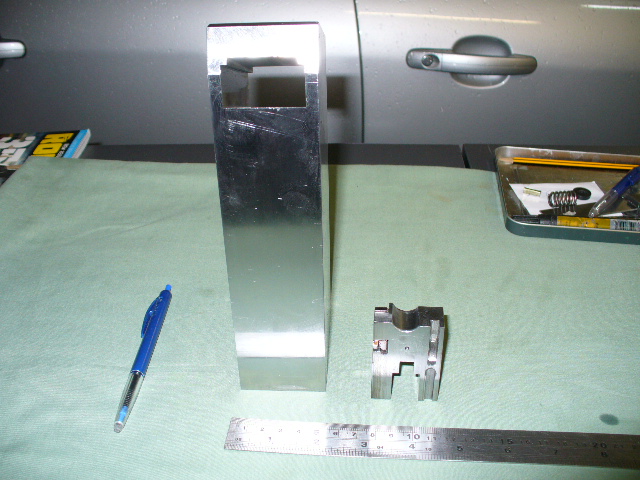

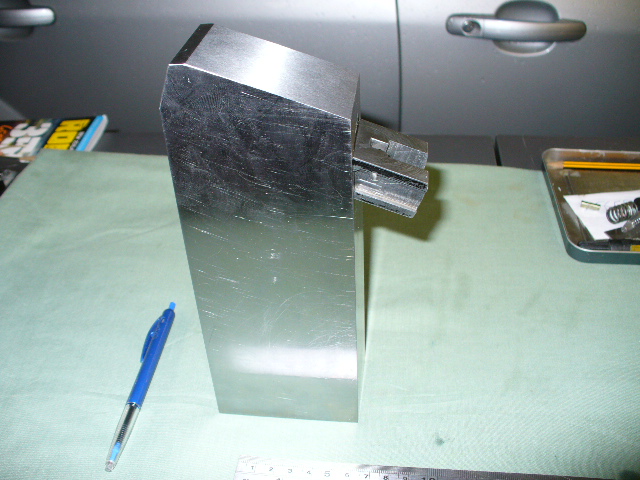

Hi guys, I`m a happy camper, have just got my block of 4140 steel back from the machinist with the breech block hole cut out and my breech block fits in a nice snug oily fit. It has also been squared up by grinding for good datum points, so as they say, I`ve got my work cut out for me, but lots more to do. Some pics before I stuff it up. Homebrew.357.

,

, , This is the precision I can not do ,

, This is the precision I can not do ,

-

30-05-2015, 08:50 PM #133

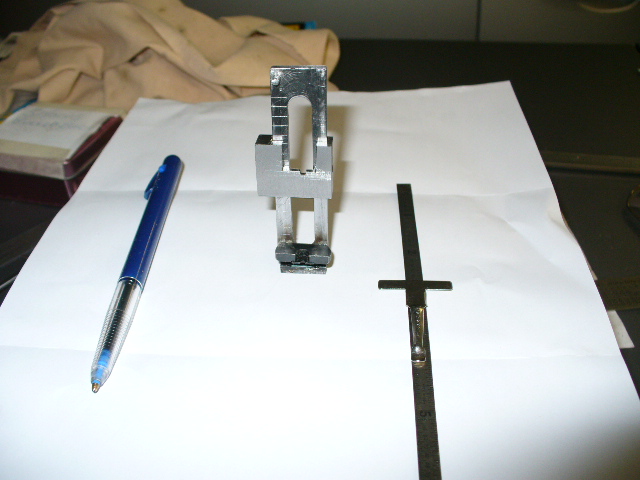

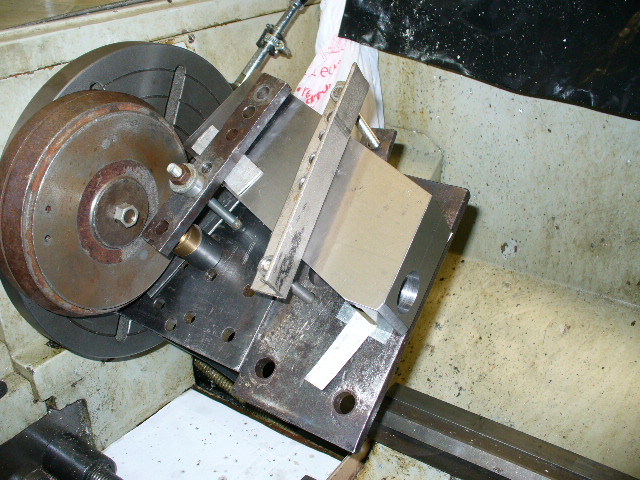

Hi, hopefully this is the precision I can do, b/block mounted on top slide after marking out centre for barrel hole and then drill with small and larger drills. Change to milling cutters to plunge cut hole larger and change to boring bar for a hole size of 1.070",and then will have to thread it on the saddle as well. The threading tool held in four jaw chuck and adjustment out using two of the jaws ever so slightly. Will have to remove the tail stock so I can test the barrel for fit, by driving saddle to back of the lathe while still in threading mode. So this is what you do if it won`t fit on your faceplate .

, Homebrew.357. P S, All so have threaded the Sharps barrel, 1.5metric.

, Homebrew.357. P S, All so have threaded the Sharps barrel, 1.5metric.

,

, , Getting there.

, Getting there.  .

.

-

01-06-2015, 09:25 PM #134

Hi, As you can see I have threaded the barrel end ready to fit in the receiver and as I said it will not fit on my face plate, but with right low down cunning, it did!," there`s ways and means". So with the angle plate bolted to the f/plate, and the rec/block clamped to that , it took all day to git it running true to side, face, and hole. Now I can cut the thread and test the barrel for fit, I think and if not will just have to remove the tailstock. Will take it real slow, Cheers, Homebrew.357.

, boring bar to finish size.

, boring bar to finish size.  , It takes low cunning and a lot of junk.

, It takes low cunning and a lot of junk. , And some nuts and bolts.

, And some nuts and bolts.

-

03-06-2015, 09:22 PM #135

After some careful but slow thread cutting I finally was able to screw in the barrel with plenty of grease so it would not jam up on me as I wanted a tight thread. It now screws in nicely with a bit of presser and when tightened up there is a .050" gap with the breech block and barrel chamber face, as I left it short for final machining of barrel lip to receiver face and head spacing. Will have to cut away about 70% of the steel block to get it looking like a Sharps receiver , but must, must take it carefully so there`s no stuff ups, measure three times and cut once!, if I cut it off, carn`t put it back. Cheers,Homebrew.357.

,

,

Similar Threads

-

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM -

Anyone got a lathe at home

By specweapon in forum Projects and Home BuildsReplies: 12Last Post: 14-07-2014, 09:55 PM -

Is there anyone in Dunedin that can drive a lathe?

By gimp in forum Firearms, Optics and AccessoriesReplies: 20Last Post: 19-02-2012, 06:34 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

419Likes

419Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks