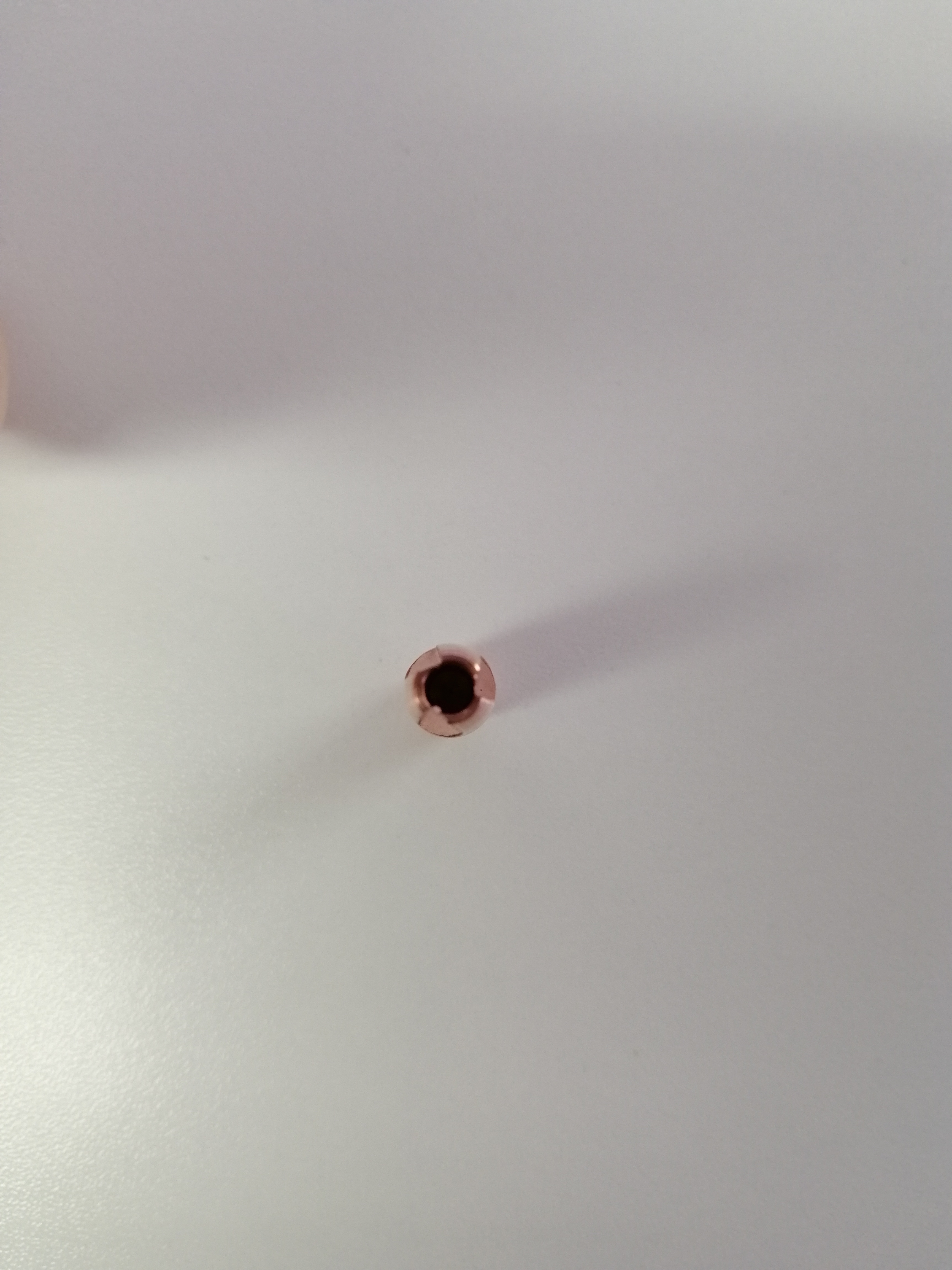

Turns out that when an engineering firm has a CNC lathe and most of its staff are hunters, eventually someone starts designing solid copper bullets for their 300blk.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 9 of 9

16Likes

16Likes

Thread: Monolithic copper hollowpoints

-

27-12-2024, 03:14 PM #1Member

- Join Date

- Sep 2014

- Location

- Dunedin

- Posts

- 1,453

Monolithic copper hollowpoints

-

-

27-12-2024, 03:17 PM #2Member

- Join Date

- Sep 2014

- Location

- Dunedin

- Posts

- 1,453

Ours pictured next to a Peregrine one, I was finding the cup of the seating die was breaking the three pre-defined petals of the bullet, so I designed a seating stem that pushes against the inside of the metplat.

-

27-12-2024, 03:28 PM #3

I love it. Have you tried them out yet?

I have been playing around with the same idea, but in 338.

What insert do you use for copper? I am getting mixed results with aluminum inserts and am contemplating getting some PCD to try.

-

27-12-2024, 03:39 PM #4

very clever indeed

Trust the dog.........................................ALWAYS Trust the dog!!

-

27-12-2024, 04:40 PM #5Member

- Join Date

- Sep 2014

- Location

- Dunedin

- Posts

- 1,453

-

27-12-2024, 04:47 PM #6Member

- Join Date

- Sep 2014

- Location

- Dunedin

- Posts

- 1,453

I think the copper he's using is pretty pure and soft, so we've used similar ribs to the Peregrine ones to change the contact area.

-

28-12-2024, 11:17 AM #7

Look great.look forward to hearing the terminal results.

75/15/10 black powder matters

-

28-12-2024, 01:29 PM #8Member

- Join Date

- Jun 2013

- Location

- Middle Earth

- Posts

- 4,573

Have you seen the new Barnes bore rider long range projectiles?

An interesting concept:

https://www.youtube.com/watch?v=hGMqyi5gVQw

-

28-12-2024, 04:45 PM #9Member

- Join Date

- Jul 2012

- Location

- Timaru

- Posts

- 884

Coolant concentration can be quite important. Higher is better.

CNC Machining

Hgprecision.net

Similar Threads

-

Reloading for Hammer monolithic pills

By chainsaw in forum Reloading and BallisticsReplies: 3Last Post: 27-11-2024, 10:02 PM -

308 and monolithic

By micknz in forum Reloading and BallisticsReplies: 11Last Post: 25-11-2024, 07:50 AM -

Monolithic Projectiles

By WillB in forum Reloading and BallisticsReplies: 19Last Post: 19-11-2018, 09:53 AM -

Monolithic projectiles

By Boar Freak in forum Reloading and BallisticsReplies: 20Last Post: 07-09-2015, 08:28 PM -

monolithic pills

By baldbob in forum HuntingReplies: 7Last Post: 28-02-2013, 04:55 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks