Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 106 to 119 of 119

Thread: New old lathe

-

24-07-2016, 01:48 PM #106Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,379

Boom, cough,cough,cough

-

-

24-07-2016, 01:49 PM #107Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,379

-

24-07-2016, 10:03 PM #108Member

- Join Date

- Jan 2016

- Location

- Omaru

- Posts

- 565

-

10-08-2016, 10:16 PM #109Member

- Join Date

- May 2015

- Location

- Parahaki, Whangarei

- Posts

- 1,274

Went to Lynfield College (west Auckland back then),

Did Engineering (metalwork - prac and theory).

My cobber and I got really excited about model pulse jet engines (V1 bomb engines).

Built one in Metalwork, filled the tank with a mix of meths and turps.

Fired it up by blasting oxyacetylene flame through it.

Was supposed to be held static, by an engineers vice.

It took a month of detentions to compensate for the hole in the workshop roof, and complaints from a couple of Blitz survivors (who recognized the sound of the jet) plus a few strokes of the flexibamboo.

Never did find the vice or engine either - despite the aerodynamics being similar to a lead balloon.

-

10-08-2016, 10:42 PM #110Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,159

-

11-08-2016, 10:11 AM #111Member

- Join Date

- May 2015

- Location

- Kapiti Coast

- Posts

- 1,085

Radio Spares has them: Same day despatch on Twist Link Belting parts | RS Components

Free delivery on web orders too.

-

11-08-2016, 10:58 AM #112

These guys Conveyor and Power Transmission Specialists | Conveyor and Transmission Ltd - Contrans just made me two for this old girl .Fast service as well as cheapish

I didn't fancy taking it all apart again either. Just has a joining pin. Piece of string, measure at or near center of adjustment.

Too easy. VSD for any speed under the sun plus reverse to fix things for when you take to much off

"This is my Flag... Ill only have the one ..

"This is my Flag... Ill only have the one ..

-

11-08-2016, 03:24 PM #113

-

11-08-2016, 10:46 PM #114Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,333

When I was a kid learning to use the gear in my uncle's engineering shop, I was always amused by his old flat bed lathe that was run by an overhead electric motor and a 3-speed flat belt set-up. To give a better range of speeds (and reverse) he mounted a pre-war ford V8 gearbox upside-down between the motor and the top pulley. To change speeds you just rerached up to the gear stick and selected what you wanted. It looked mickey mouse but it worked well!

-

11-08-2016, 10:56 PM #115

-

15-02-2017, 01:53 PM #116Member

- Join Date

- Sep 2016

- Location

- Waikato

- Posts

- 184

@Happy what kind of lathe is that? It looks similar to my selson lathe. Will post up a pic of it when I get home

-

15-02-2017, 04:37 PM #117

-

17-02-2017, 11:46 AM #118

Quite enjoying this thread. Got to love old lathes - not much on them that can't be fixed or rebuilt.

We had a guy like that who was ultimately banned from all our shops - he managed to get his tie pulled into a big hand held belt sander that he was inexplicably trying to sand a very small loose piece of wood with; he almost killed himself by poorly mounting a very large and unbalanced piece of wood in the wood lathe, starting it at a high rpm and then diving at it with a gouge, which ultimately ended up in the ceiling, and finally, spent a good minute trying to cut through a piece of wood that had a large bolt in it with a chop saw, and wasn't noticed until the industrial vac system burst into flames and blew smoke and burning sawdust back through the vents into the shop. The fire department put the vac system out and he was never allowed inside any rooms with moving equipment again.

I'm fairly certain he runs a couple McDonald's franchises now. Nice guy, just not situationally aware.

-

18-02-2017, 11:06 AM #119Member

- Join Date

- Sep 2016

- Location

- Waikato

- Posts

- 184

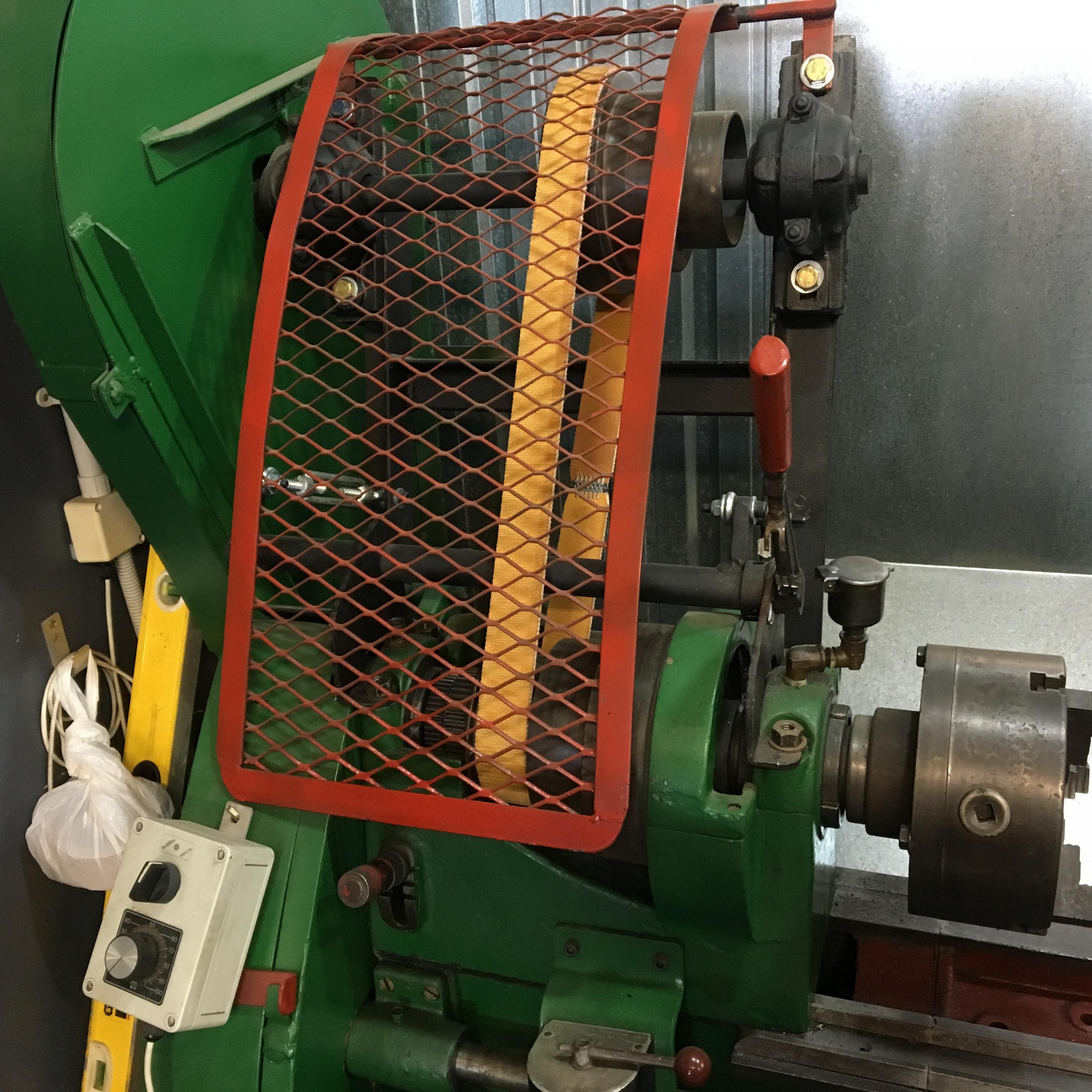

Here's my old lathe

Shes pretty tired, the wear in the front headstock bearing causes a bit of chatter on larger pieces and when parting off. Fortunately the whole spindle/chuck/headstock assembly is so heavy it doesn't really affect turning of smaller peices. Long term I would like to get a better lathe or refurbish this one, but I'm not sure how to go about doing that. It would probably involve casting new bearings and bluing/scraping til the clearance was just right.

Similar Threads

-

The new cnc lathe has arrived.

By DPT in forum DPT MachinistsReplies: 45Last Post: 17-03-2015, 02:44 PM -

Anyone got a lathe at home

By specweapon in forum Projects and Home BuildsReplies: 12Last Post: 14-07-2014, 09:55 PM -

Is there anyone in Dunedin that can drive a lathe?

By gimp in forum Firearms, Optics and AccessoriesReplies: 20Last Post: 19-02-2012, 06:34 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

122Likes

122Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks