Hey guys,

I'm looking at buying a quick change tool post for my lathe, but there are a few options out there.....

Can any of you with experience please help with advice please?

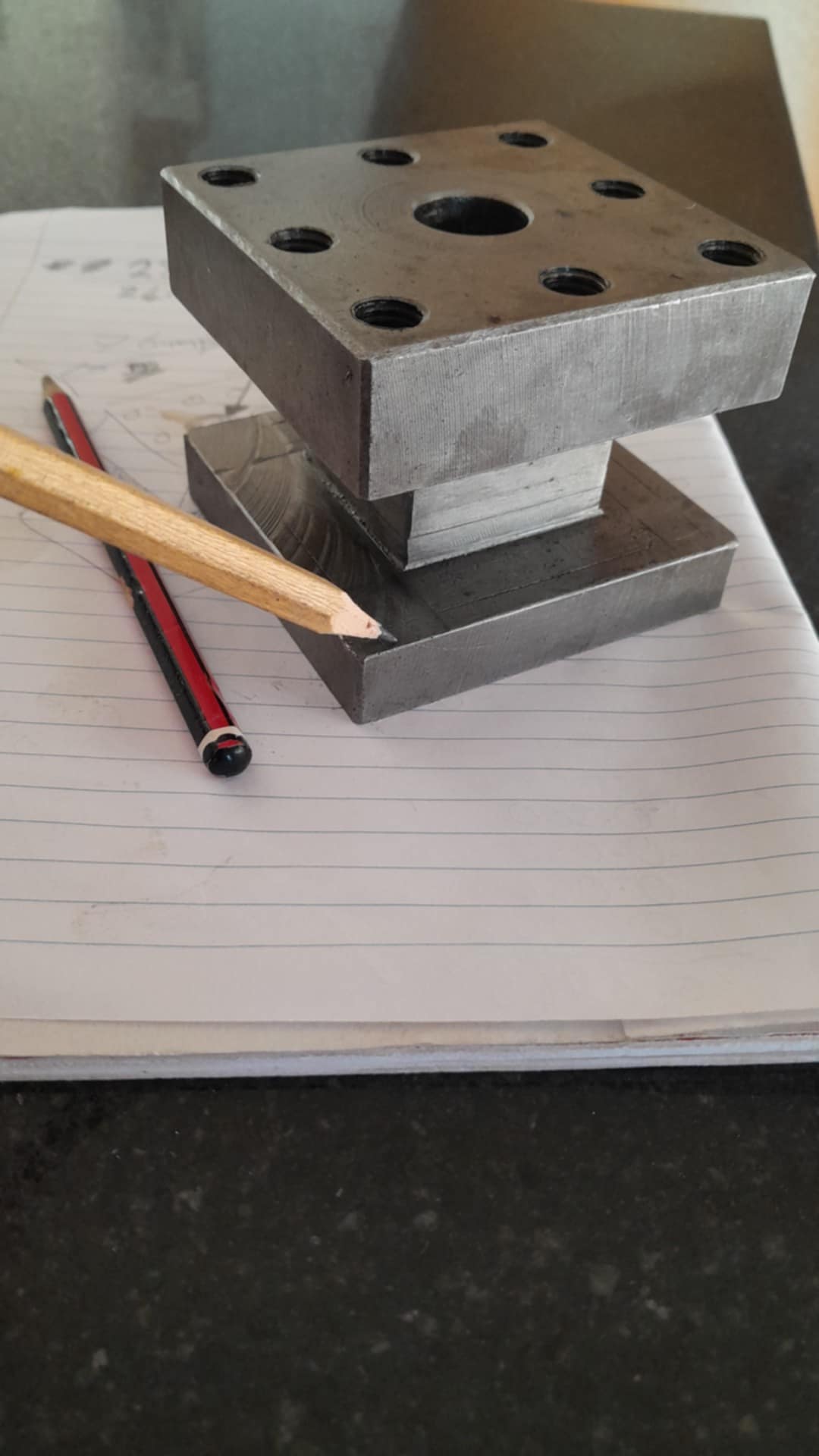

Ill attach my existing tool post dimensions below.

Thanks in advance, 40mm

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 55

-

23-03-2025, 09:50 AM #1

Quick change tool post, advice please

Use enough gun

-

-

23-03-2025, 10:20 AM #2

Or........ I tried using a HSS fly cutter to machine my tool post but the hardened steel ate the fly cutter!

Anyone got a suggestion to help machine it please?

Ive asked a mate if a surface grinder will do it, but i think the side of the wheel will need to be used and I dont know if thats ok?Use enough gun

-

23-03-2025, 10:24 AM #3

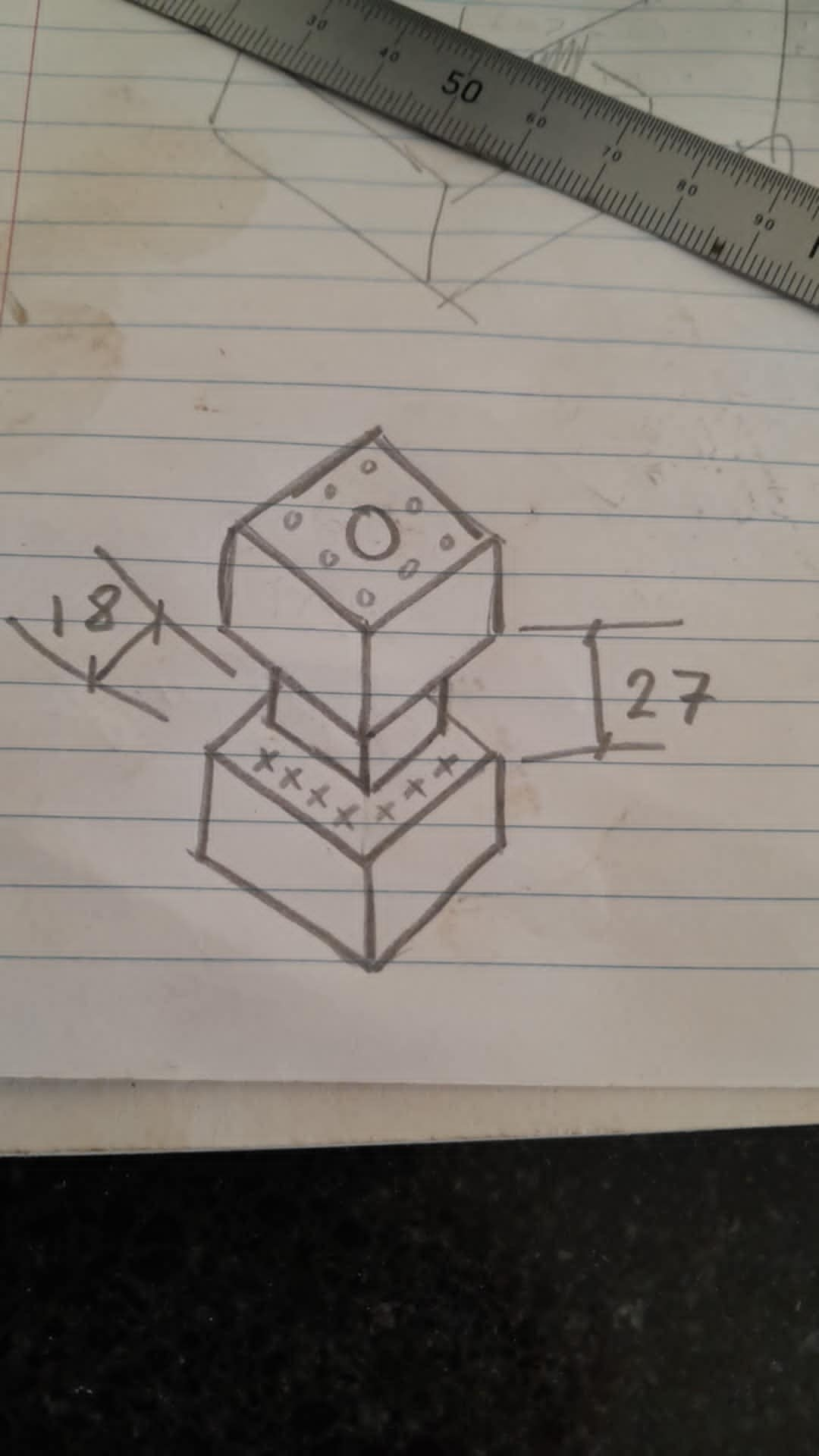

This is the area i need to remove/grind true and flat

This is the area i need to remove/grind true and flat

the area with the xxxxx's is to be ground etc

Use enough gun

the area with the xxxxx's is to be ground etc

Use enough gun

-

23-03-2025, 10:39 AM #4Member

- Join Date

- May 2023

- Location

- South

- Posts

- 805

fyi carbide stuff from aliexpress works well and is cheap.

I hardly bother with hss anymore.

you wont regret buying a decent quick change toolpost and enough inserts (except when you buy it)

-

23-03-2025, 12:31 PM #5Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,378

Tried Chevpac or Machinery Hse?

Boom, cough,cough,cough

-

23-03-2025, 12:33 PM #6Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,378

-

23-03-2025, 01:05 PM #7Member

- Join Date

- Jul 2021

- Location

- Whangarei

- Posts

- 503

I use pretty much only carbide now, works well and lasts for ever…. These guys are well priced and quick on delivery. https://carbidenz.co.nz/

Run them fast and climb mill for the finishing cuts

-

23-03-2025, 01:57 PM #8Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,954

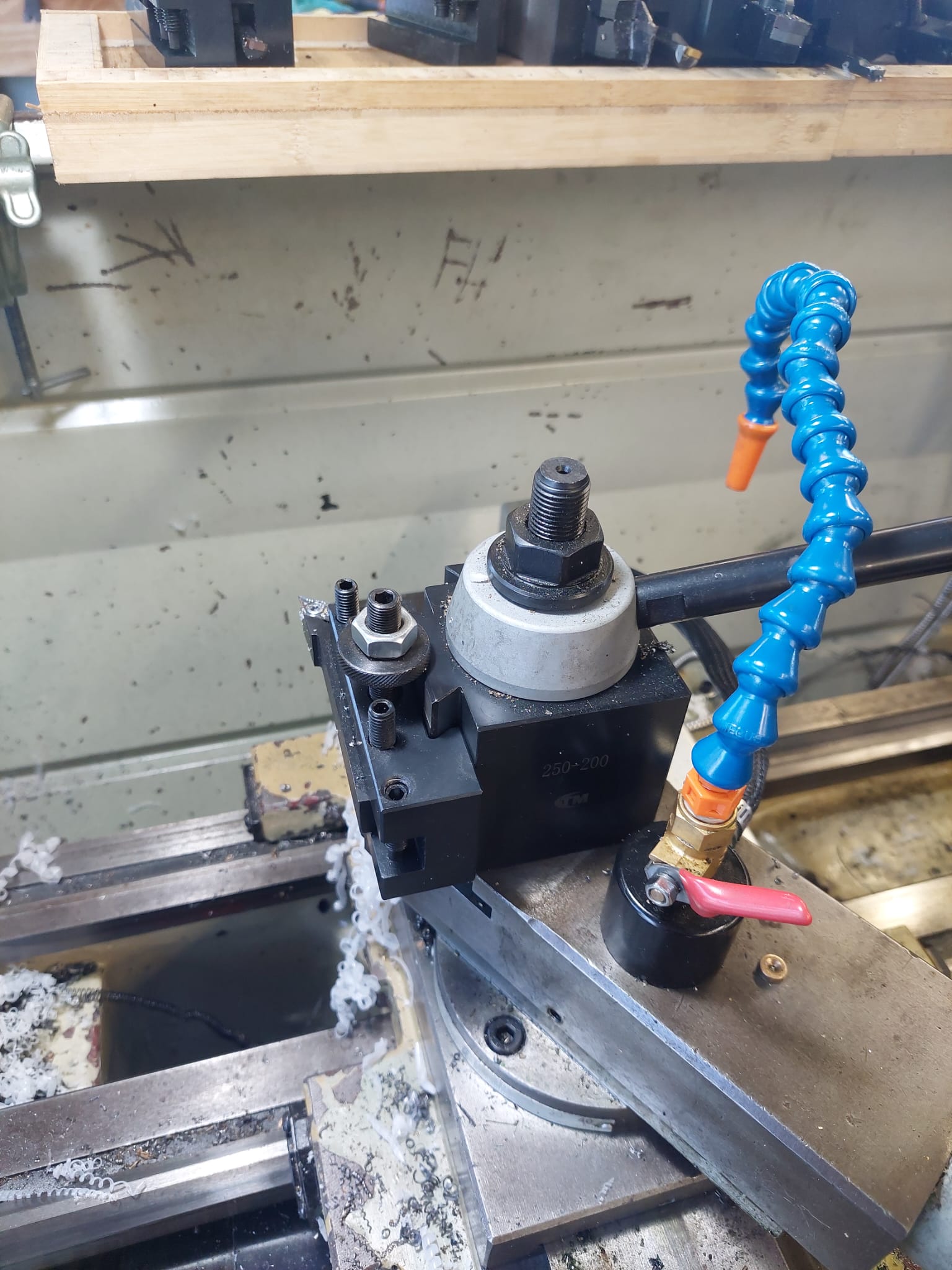

I'd have a good look at the 100 series quick change toolposts. I have a 200 series on my lathe, very simple, easy, quick and more solid than the machine. I have 5 tool adapters, and a knurling tool and a parting off blade holder...

Likely that tool post will have a hard skin, but nothing but butter underneath so if you chop through it it will not hold up to a hammering like an interrupted cut with a bit of knock to it????

-

23-03-2025, 02:33 PM #9Member

- Join Date

- Jul 2021

- Location

- Whangarei

- Posts

- 503

-

23-03-2025, 02:52 PM #10Member

- Join Date

- Dec 2011

- Location

- Te Awamutu

- Posts

- 1,054

I've got two spares of these. One used and one unused: https://www.machineryhouse.co.nz/l292

Use one on my lathe.

-

23-03-2025, 02:52 PM #11Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,954

Yep, those are the 200-series toolposts - bloody good. Mine I got for several hundy I think, and picked up two more toolholders later. Do not regret it one bit.

I still use a lot of HSS - as I tend to turn a lot of oddball stuff like urethane, engineering plastics and reaching into small areas and carbide is poo for that. Also, things that aren't free cutting can be nasty with carbide but with HSS you can give them a bit more hook and really get under the hard bit on top.

The 100 series I think is closer in size to what the one up top is for size, but might be able to get away with the 200? 200 series has more meat and more surface area at the bass so is more rigid. The center height measurement is what will dictate the post you need.

-

23-03-2025, 02:55 PM #12Member

- Join Date

- Dec 2011

- Location

- Te Awamutu

- Posts

- 1,054

-

23-03-2025, 03:40 PM #13Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,954

Yeah, them spendy though. I have HSS here already ground and it was free haha.

-

23-03-2025, 03:46 PM #14

I tried that, but it still wore the HSS down.

I am an amateur though.... so likely I had a hand in that result!Use enough gun

-

23-03-2025, 03:48 PM #15

Similar Threads

-

Inline Fab quick change top plate

By Tommy in forum Reloading and BallisticsReplies: 2Last Post: 22-09-2018, 07:57 PM -

New Varimax Quick-change muzzlebrake

By dfmaisey in forum Dean Maisey GunsmithReplies: 22Last Post: 19-01-2015, 08:48 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

37Likes

37Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks