Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 166 to 180 of 339

Thread: Self isolation gun projects

Hybrid View

-

10-04-2020, 05:51 PM #1Member

- Join Date

- Jan 2018

- Location

- kaiapoi

- Posts

- 7,359

Last edited by csmiffy; 10-04-2020 at 06:00 PM.

-

10-04-2020, 06:37 PM #2Member

- Join Date

- Aug 2019

- Location

- South Otago

- Posts

- 3,994

-

09-04-2020, 05:02 PM #3Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,335

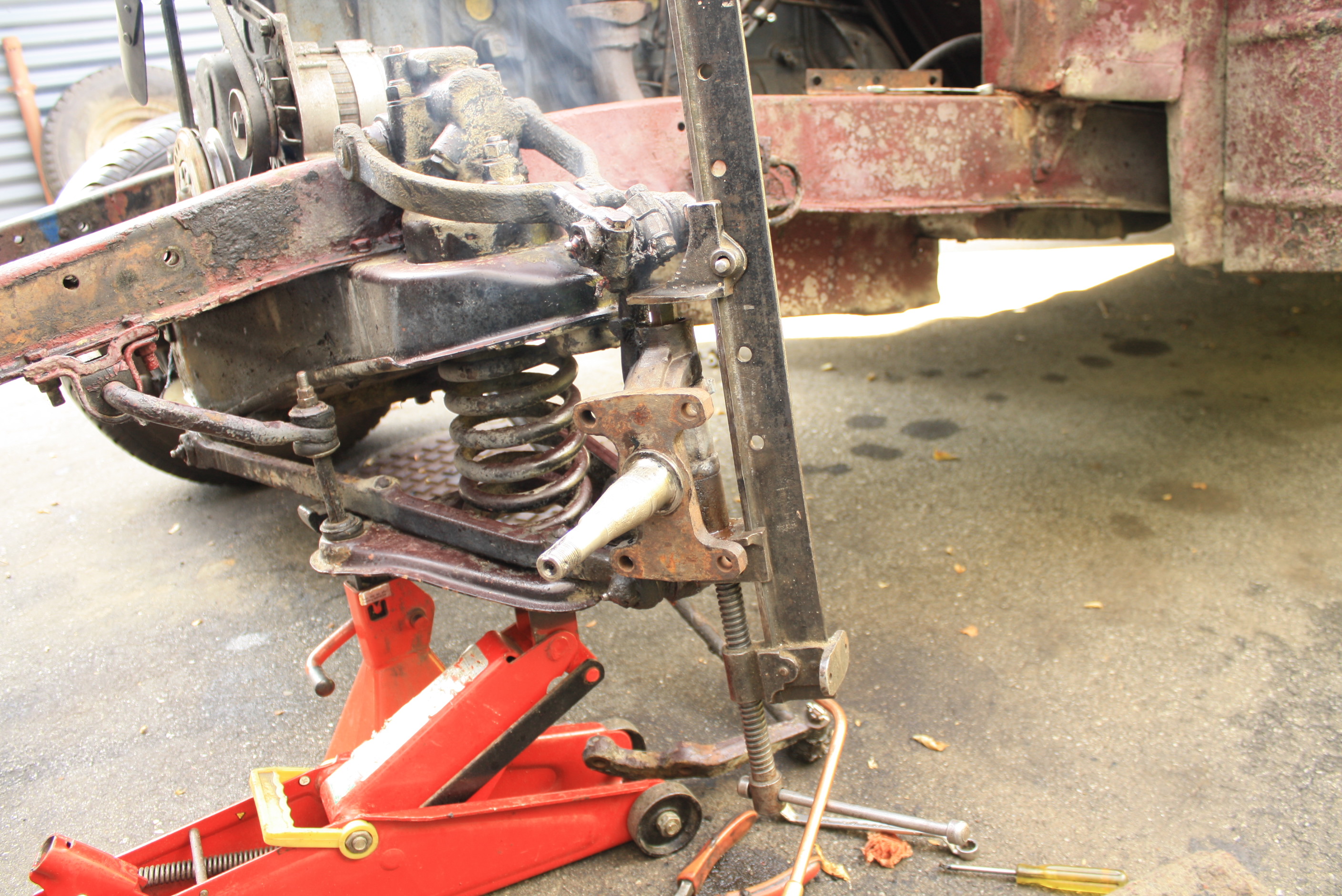

A little 'Ahh shit!' moment. The kingpin is well rusted into the eye. I have had the eye glowing red while under extreme pressure with the cramp only got a few thou out of it. I will let it soak overnight in penetrating oil and have a go again tomorrow. If we get a frost tonight I will hit the eye with the gas again and that might do it if I can keep the pin cold, speed being of the essence!

-

09-04-2020, 05:06 PM #4northdudeGuest

sit the suspension arm on something solid and try a decent square hit with a heavy sledge hammer the jack will absorb the shock it you use jack to support the arm

-

09-04-2020, 05:13 PM #5Member

- Join Date

- Aug 2019

- Location

- South Otago

- Posts

- 3,994

ATF and acetone mix is meant to be the bees knees for ‘unseizing’ things

That and a b.f.h.!

PS: have you tried loading up the clamp pressure and then giving the top of the clamp a hard whack with a hammer while supporting the other end of the clamp?

-

09-04-2020, 05:13 PM #6Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,172

Id sit down -with a nice glass of single malt --snuggle up close ..and in your most sultry voice murmur

you do as I say

Or

Chuck Norris is on the next waka headed this way and you will know what pain is all about

I trust im understood!!

-

09-04-2020, 05:33 PM #7Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,335

An unfortunate design means the upper control arm curves out over the line of the king pin and you can only get an angled blow at it, about 10 degrees off line. I got another 1/8" out of it a few minutes ago so will leave it soaking overnight. A good point about the jack absorbing the blow. I will put a solid support under the spindle tomorrow.

-

09-04-2020, 08:12 PM #8Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,172

now listen old chasp -ive a psycho babble solution to your problem .

take another gulp of scotlands finest

lean in close to the offending joint

and in remembrance of one of countrys finest men GeorgeJones

croon

"I FALL TO PIECES

AND I SUGGEST YOU FUCKING DO TOO

option two

If you know any old westcoast coal miners -

a suitably applied dollop of Nobels #5

lavishly wrapped about that reticent joint

and ignited once youre undercover in the dunny or outside

mat prove you wont take no for an answer

just sayin like

-

09-04-2020, 08:30 PM #9Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,335

-

09-04-2020, 10:49 PM #10Member

- Join Date

- Jan 2018

- Location

- kaiapoi

- Posts

- 7,359

On the yucky rusty tight fitting stuff it's like previously mentioned.

A bit like a slipping socket. If there is the slightest give any impact is lessened significantly.

-

10-04-2020, 10:29 AM #11

You`v all got it wrong, you pour the single malt extract over the flaming pin, then the roasting trick, breath in the heavenly fumes.

,, now what was I meant to be doing.

,, now what was I meant to be doing.

-

10-04-2020, 05:10 PM #12Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,335

A good Friday! Thanks for the tips! The support block under the spindle certainly helped but I had to make up a special drift as well to properly direct the hammer blows. Suspension, king pins and disc brakes done (the 8" wheels are only temporary till the new 6" front ones arrive). Next will be to remove the seats and open up the floor, then disconnect the drive train. You can see from the second photo that she is a fairly tidy old girl for a 73 year old.

-

10-04-2020, 05:22 PM #13Member

- Join Date

- Aug 2019

- Location

- South Otago

- Posts

- 3,994

Excellent work gundoc!!

Watch when you mount the diff that you make an allowance for the fact that the center bolt of the rear springs won’t have the dif in the right location if you mount it in the traditional manner otherwise your dif will be too far to the rear. ( or front, it’s been a decade or two si ce I last looked a. Chev torque-tube drive line!)

To get an idea have a look at the factory pivot point on the dif.

And don’t cut the mounts off the original dif and weld them onto the new dif, they’re designed to operate with a torque-tube.

-

10-04-2020, 08:12 PM #14Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,335

-

10-04-2020, 06:25 PM #15Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,815

@csmiffy easily available where ?

I would buy one in a flash if I could find one

Just about to go practice on an old barrel to see how to turn one down to 1/2"

Similar Threads

-

My projects last 12 months!

By Gloves in forum Projects and Home BuildsReplies: 7Last Post: 21-07-2018, 06:06 PM -

DIY Leather Projects

By LOC in forum Projects and Home BuildsReplies: 22Last Post: 25-01-2017, 06:33 PM -

Dog projects

By RCGSP in forum Trial, Pedigree and Bird DogsReplies: 35Last Post: 18-06-2013, 09:12 PM -

Dog projects

By RCGSP in forum DogsReplies: 21Last Post: 09-01-2013, 01:15 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

697Likes

697Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks