Interested to hear if you've tried paper patching yourselves.

A while back I read an article in a NZ shooting mag about some guy with a "hollow" 1895 303 and he managed to seal the gas cutting with paper patching like the old cowboys used to do. Thought it was kind of cool so did some googling and lurking on forums. Some of those yanks (and Kiwis) are quite clever buggers.

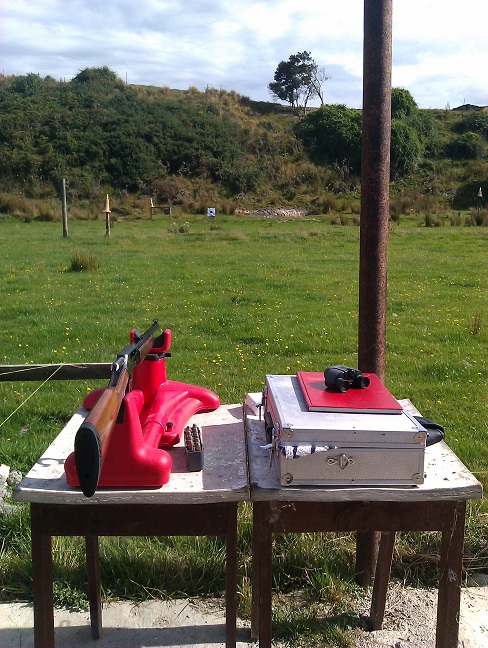

Anyhoo this is some of my 45/70 experiments:

Started with some TL452-230TC's, wrapped "cut to size" wet paper parallelograms and let dry for day or so.

I've already had the sermon read to me that 230gn 45 colt projectiles will never stabilize in a 45/70 so I was wasting my time and had to get some > 300gn.

I've got an unemployed 6 banger mold from when I had a 45LC and was dreaming of a 1911. The lead is from soft old leadheads, fine to use though as it doesn't touch the barrel.

To fit easier in the case and a bit of peace of mind I like to run them through a 0.457" sizer with a bit of lube . Sizing lube works good but not catastrophic if you don't lube.

Used no crimp but rather used the 45/70 sizing die with decapper out (seated way out on the press) so that the case is gently sized around the projectile till the desired amount.

I don't trust using the mag in case of "stove piping".

I've loaded with Trailboss as I'm only punching paper and who needs all the recoil eh. The masking tape is for patching the target here but some have used it and probably not successfully.

@50 yards it's hardly MOA but still minute of pig. I blame my eyes more than anything.

You got to love those big holes.

The paper should confetti at the muzzle and not stick on the bullet to the target.

It was quite scary trying this out at the start.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 14 of 14

Thread: Addicted to Paper Work

Hybrid View

-

02-06-2013, 10:26 PM #1

Addicted to Paper Work

Last edited by Chupacabra; 02-06-2013 at 10:32 PM.

-

02-06-2013, 11:05 PM #2Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,374

Load both 45/70 and 577/450 paper patched, for your paper use old dress patterns, it close to onion paper and comes in diff thicknesses

Max wrap 3 times round, measure the circumference of sized projectile and and multiply for # of wraps, make a pattern out of plastic and cut the paper shape out with a sharp knife/razor, wet and wrap. The girls wrapping for the 577/450 could do about 1200 per day, something to work on. No leaded barrel in theory, I do still size and lube my projectile. Very satisfying.

-

03-06-2013, 11:48 AM #3

Good idea on the old pattern.

You start looking at paper in a whole new way and find yourself firing everything from baking paper to notepads down your barrel.

You start looking at paper in a whole new way and find yourself firing everything from baking paper to notepads down your barrel.

I hear some paper can have clay in it so lubing is a good idea.

For my patches (2 wraps) pattern I converted every thing to metric, PIxD+PI(D+2(paper thickness))-0.25mm to allow for the paper bending up onto the 2nd wrap. About this time I was thinking I was a fancypants mathmagician when I got slapped down with the big ol variable that paper stretches when it gets wet. Doh! Got there in the end by rolling a ribbon of paper twice and measuring the required length.

With the 45/70 printer paper works ok so made up a pattern and print out a sheet of them at a time

Last edited by Chupacabra; 03-06-2013 at 12:10 PM.

-

02-06-2013, 11:17 PM #4

For the uninitiated why do you do this?

Sent from my GT-S5360T using Tapatalk 2"Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

-

03-06-2013, 12:15 PM #5

Bloody good question I ask myself sometimes

For me two main reasons; You know the sense of satisfaction you get from reloading, it's a whole next level. It's way cheap so you get to make a lot more booms for your buck.

Like Maca said, little fouling and I think it might even help clean your barrel.

-

02-06-2013, 11:28 PM #6Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,374

Because we dont own 308s, but mainly to size it to the bore on BP guns and not have the soft lead touch the bore. Also lubing is not a problem and I wipe the bore every shot. And I can fit it into my brass and don't crimp, load by hand with a hammer

-

03-06-2013, 03:22 PM #7

You BP chaps are hardcore but err umm yeah nah I PP 308win with smokeless too...

but err umm yeah nah I PP 308win with smokeless too...

My C312-185-1R mold knocks them out with a .301 nose (you would think if they were meant to work in a 303B they would have .303-.304 nose). Stick em in the lathe and cut the bands down to match .301.

Got excellent groups with Trailboss. Had high hopes that the leadhead lead would work like a Vmax so I could take the 308 out bunny busting but was disappointed to find a starting load of W748 will blow them straight through 2-3mm of steel.

Have a special little project in mind of tweaking the mold to hollow point and making homemade ballistic tips.Last edited by Chupacabra; 03-06-2013 at 03:49 PM.

-

03-06-2013, 10:32 PM #8Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,374

-

04-06-2013, 09:22 AM #9

-

02-06-2013, 11:35 PM #10

So the advantage is you can use soft lead presumably to get decent expansion on animals instead of harder alloys and those gas check things with out lead fouling your bore ?

Sent from my GT-S5360T using Tapatalk 2"Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

-

03-06-2013, 12:37 AM #11Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,374

You can use gas checks on BP to stop erosion of the rear of the projectile,BP burnts slowly with lots of heat. I also use wads between the powder and the projectile, one milk carton cardboard and then a lube biscuit. Lube is very important to stop hard crusting of burnt BPIn the bore. The projectile will bump up on ignition into the rifling and form a seal,and grip, round ball does the same. 500 gr of lead doing 1300 fps is pretty devastating.

-

03-06-2013, 10:24 PM #12

Macca you dont know were a 577/450 henry could be brought?

Rule 4: Identify your target beyond all doubt

OPCz

-

03-06-2013, 10:28 PM #13Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,374

-

03-06-2013, 10:29 PM #14

I have a mate that would love to buy one, cheers let me know

Rule 4: Identify your target beyond all doubt

OPCz

Similar Threads

-

i think iam now addicted to geese

By major in forum Game Bird HuntingReplies: 2Last Post: 12-11-2012, 04:20 PM -

CZ action needs work!

By Malhunting in forum Firearms, Optics and AccessoriesReplies: 14Last Post: 13-07-2012, 09:48 AM -

Hows this for some Lab work...

By EeeBees in forum DogsReplies: 8Last Post: 02-05-2012, 08:55 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

1Likes

1Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks