A small production run could be in order, to buy a factory one is about $600!

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 30 of 90

Thread: Annealing questions

-

13-01-2016, 07:55 PM #16Using Tapatalk

-

-

13-01-2016, 07:59 PM #17

Good idea. Me first😆

Only need one for bulk .223 brass to be fair.

Sent from my SM-G900F using TapatalkDo what ya want! Ya will anyway.

-

13-01-2016, 09:21 PM #18

@R93

$2.4million usd

Or slightly less if you supply all the parts.

Cheers

Pete

-

13-01-2016, 09:23 PM #19

Cheap at twice the price.😆

Sent from my SM-G900F using TapatalkDo what ya want! Ya will anyway.

-

13-01-2016, 09:28 PM #20

Yep

That's what I thought.

A good keen man like you would build one of these in an afternoon.

I'll put up the link to the materials/parts list and cutting instructions

Here's the link

http://www.shootingaustralia.net/for...er-black-betty

Cheers

Pete

-

13-01-2016, 09:40 PM #21

-

13-01-2016, 09:47 PM #22

Can't even join as it says my email is invalid. It never has been anywhere else.

Any chance you could make it visable here?

Sent from my SM-G900F using TapatalkDo what ya want! Ya will anyway.

-

13-01-2016, 09:50 PM #23

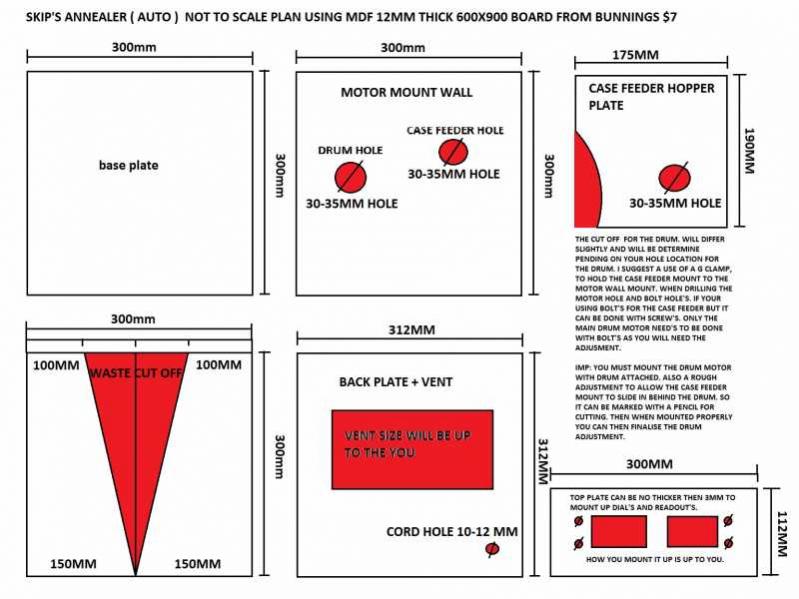

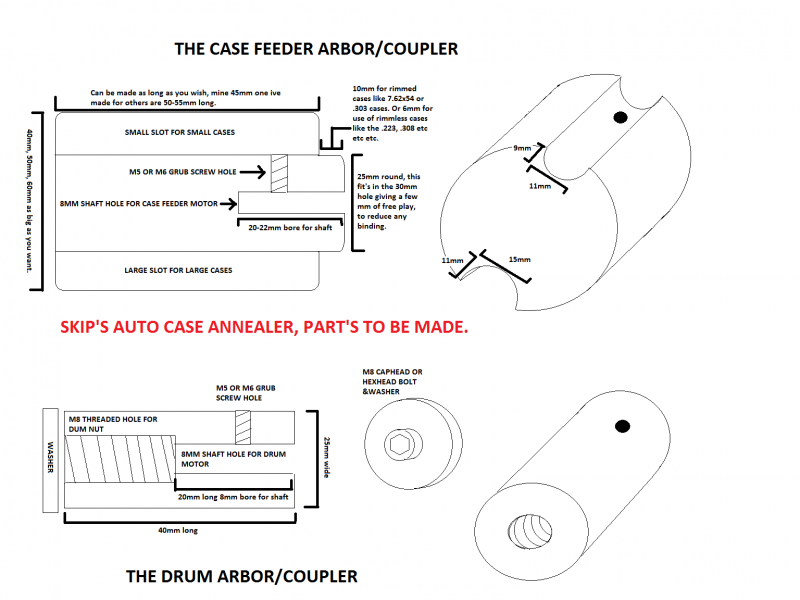

Ok here is a ebay list and a rough drawing of the dimension's i used to build my annealer.

First the rough measurement's. Your's can differ and you can chop n change this sizes as you like. This is a ball park guide ( well this is how i built mine ) Not i haven't put the exact hole placement in as it's determined by the first hole you drill ( main drum motor ) Leave the case feeder drum hole last to drill out.

The rough total build cost is $140 that's everything if you have to buy all the bit's new. For me it was $60 as i had scavenged bit's off my older build.

from Bunning's you will need:

1x Benzomatic pencil flame torch kit

1-2x100mm long 13mm hole eyelit bolt ( This will hold the torch. od on the brass tip is 12.7mm so the internal diamiter of the eyelit bolt must be 12.7-13mm )

Bolt's, nut's, washer's, ( m5 ) Mine was M6 but i had to drill out the motor mount's. m5 threadded rod ( for drum motor adjustment 3x75mm )

1-2x Small tube of Liquid nail's $2.50 each.

Wood screw's 20mm ( I used 8g 20mm hinge screws as that's what i had in the shed. )

35mm dress nail's ( this is to pin all the mdf till the Liq nail's set's ) or you can just buy longer screw's.

Bunning's also sell timber bracket's cheap that at of the right size and shape's. to use as a ramp and case hopper side's etc. also they sell angle also flashing ( easy to bend )

If i can think of anything else i'll add to the above list.

Skip's shithouse excuse of plan's :lol:

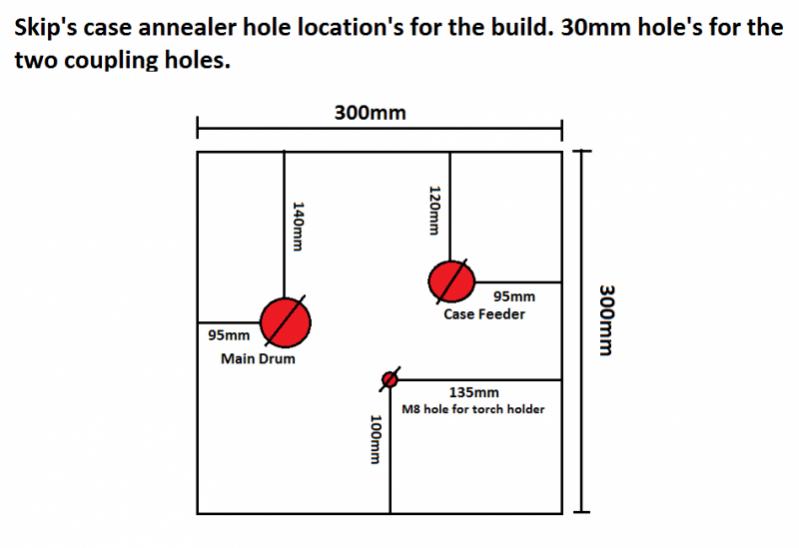

Update: the main motor drum hole and feeder hole is 30mm ( i did say 30-35 ) 30 would be better. Mine was 35 as that was a size i had in my hole saw kit i got a few year's ago

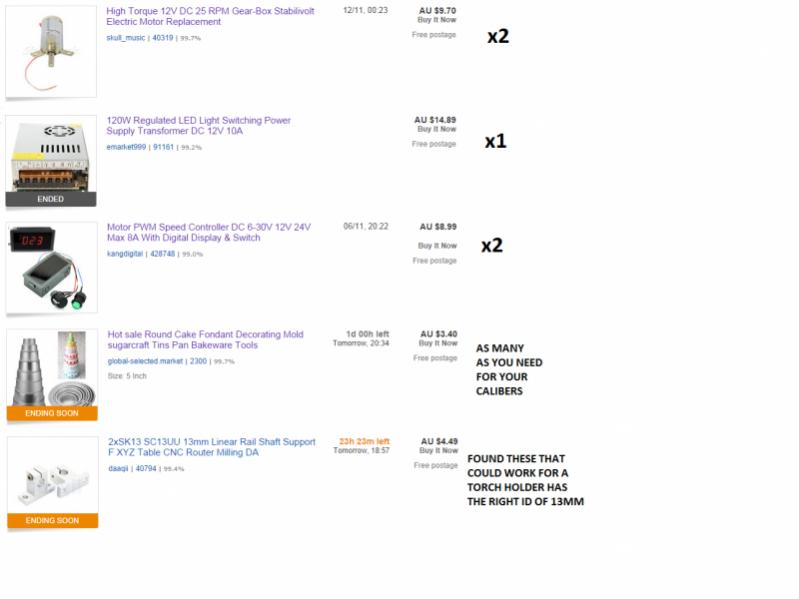

Ebay buying list: EDIT :facepalm: Thank you EBAY for having to make thing's difficult every time you update your site.

So i have come up with this to hope stop the link's turning into blank white boxes. ( NOTE: you will have to search for these as i no longer can use the link's ) Below will help your search in what i used for my build. ( i have added one extra item that i found that could be used as a torch holder )

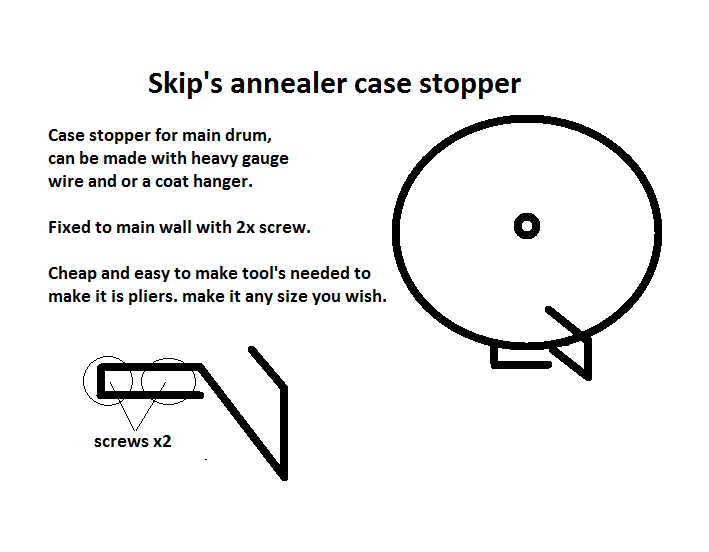

As to the cable well i am assuming just about everyone has a old cable no longer getting used, from a old PC monitor etc you can use. ( If your like me you have a box of all sort's of cable's collected over the year's. ) The build can be as cheap as you want or as expensive as you want. It depend's on how good you are on scavenging bit's for the build. You can run it all off a battery if you wish like AusHunter. For a case stopper/holder in the drum you can use a bent up bit of coat hanger as a quick cheap option ( Like Adam did in his first build )

I don't want to do a step buy step instruction, I'm not Ikea nor is the build that complex to warrant it. As to the coupling's and case arbor we'll it's been stated i can help out there ( If and when 10 member's get together ) I will then buy the material and make them up for thos ten ( ten is the number as that's the min length's, i can buy the stuff ) If GregT is willing to do it great even better, as he has the gear at home to do it where i have to drive out to go use it.

Watch this vid pause it when needed to give you a rough idea

Drum width size will be up to you: Example is for me my smallest case is .223 ( i made the dum 35mm wide ) for my largest case i made a 45mm one ) If you have larger case's i would buy the next drum size up which i think is 6" ( which is also wider )

-

13-01-2016, 09:52 PM #24

Legend.😆

Thanks Pete.

Sent from my SM-G900F using TapatalkDo what ya want! Ya will anyway.

-

13-01-2016, 09:59 PM #25

Here's some more drawings that you will need

-

13-01-2016, 10:03 PM #26

oh and it looks like Skips making them for sale.

So log onto the website and access the page if you want to buy rather than make one.

Cheers

Pete

-

14-01-2016, 06:52 AM #27

Good info Pete . Cheers for posting.

I Have Sexdaily. I mean Dyslexia! Fcuk!

-

14-01-2016, 08:54 AM #28

+1 thanks Pete.

Sent from my SM-G900F using TapatalkDo what ya want! Ya will anyway.

-

14-01-2016, 10:26 AM #29

I might have a go at one of those. I'd use one motor linked to both shafts as you ideally want them spinning at the same speed to keep in sync. Just rotate one shaft relative to the other to get the relative timing as you want. Wouldn't need to buy anything.

There are only three types of people in this world. Those that can count, and those that can't!

-

14-01-2016, 10:31 AM #30northdudeGuest

Just be careful and watch a few YouTube clips one I watched the guy was getting the brass way to hot compared to the other clips I watched

Similar Threads

-

Annealing machines?

By kimjon in forum Reloading and BallisticsReplies: 27Last Post: 28-04-2015, 01:02 PM -

Annealing Scenars

By Beavis in forum Reloading and BallisticsReplies: 9Last Post: 20-05-2014, 06:06 PM -

annealing cases

By longrange308 in forum Reloading and BallisticsReplies: 21Last Post: 19-05-2014, 09:39 PM -

Annealing machine

By R93 in forum Reloading and BallisticsReplies: 23Last Post: 14-12-2012, 07:50 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

53Likes

53Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks