If so, a few further questions should you be so kind to consider. Do you, or have you, used it to reload 2 1/2 inch as well as 2 3/4 and 3 inch hulls?

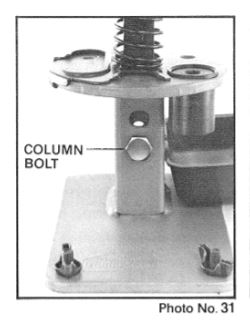

If so, then you will know that the 600 has this ability to load more than one 12 bore hull length and it is achieved without the need to insert a 1/4 inch riser plate, as required with some other MEC press's because the 600's base plate support collar for the metal column as well as the metal column, each have two holes, one positioned above the other and the insertion of a column bolt into various permutations of the column and base plate hole 's achieve this.

I have a couple of second hand 600's but the resource material available to me make no mention of the alignment of the column and base plate collar holes apart from "raising it a quarter of an inch for 3 inch hulls". As both my second hand units arrived with no indication as to what their settings of the holes were, I have no point to start from to adjust their height.

I "suspect" that they were both at 2 3/4 inch settings 's but have enough problems with column height without charging blindly on and crushing "lotsa" hulls.

SO, the knowledge I seek, Please with a side salad of thank you's, is what are the column and base plate collar holes alignment settings you use for your different hull lengths.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 1 to 4 of 4

Threaded View

-

08-08-2021, 09:31 PM #1Member

- Join Date

- Feb 2013

- Location

- Wanganui without an "h"

- Posts

- 3,023

Do you reload 12 bore using the MEC 600 Junior press?

.

Similar Threads

-

Is it 'Cold Bore' or 'Foul Bore' ?

By redbang in forum ShootingReplies: 31Last Post: 17-01-2021, 08:42 PM -

Te Matai Hut Junior

By BruceY in forum HuntingReplies: 5Last Post: 15-06-2015, 09:05 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

3Likes

3Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks