Hey,

First attempt at reloading at a mates place. He loads for his WSM and 22-250, so I bought some second hand 243 dies, powder, pills and primers for a start.

So we found that the COAL theoretical was longer than we could possibly achieve as the Nosler Varmint BT's couldn't go in any less. The COAL measured theoretically 2.752. The actual we could seat to was 2.700".

We had problems with the Hornady neck seating die. We set it up in the Redding press using the Hornady instructions. First time we found it near impossible to remove the case from the die. After 3 attempts at butchered cases I took the die apart and found that previous owner had bent the centre spindle. Ah,ha. So I pinched the spindle from the full length reseating die and started again. Much better.

We loaded up a couple of cases without powder and found that the bolt was slightly tight to close when the bullet in place, yet a resized empty case was fine? (WHY?)

We started at 42g of ADI 2208 and loaded 3 per weight of powder, incrementing in 0.3g per triple, until we had loaded to max from the ADI table which worked out nicely at 11x3 = 33 cases.

Then we headed out to the range.

three shots at a target, new target per load and took as best a time as I could for most of the afternoon.

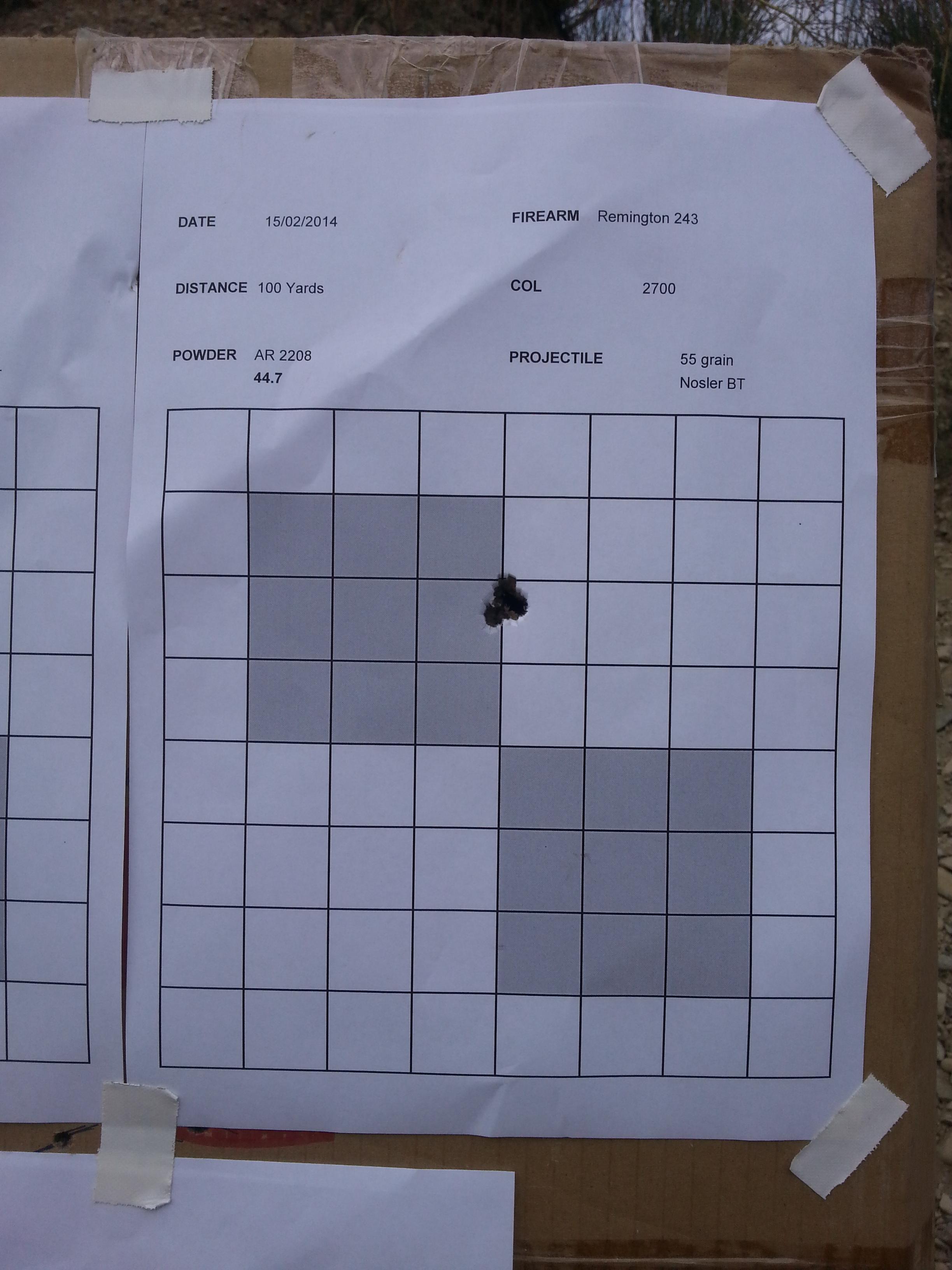

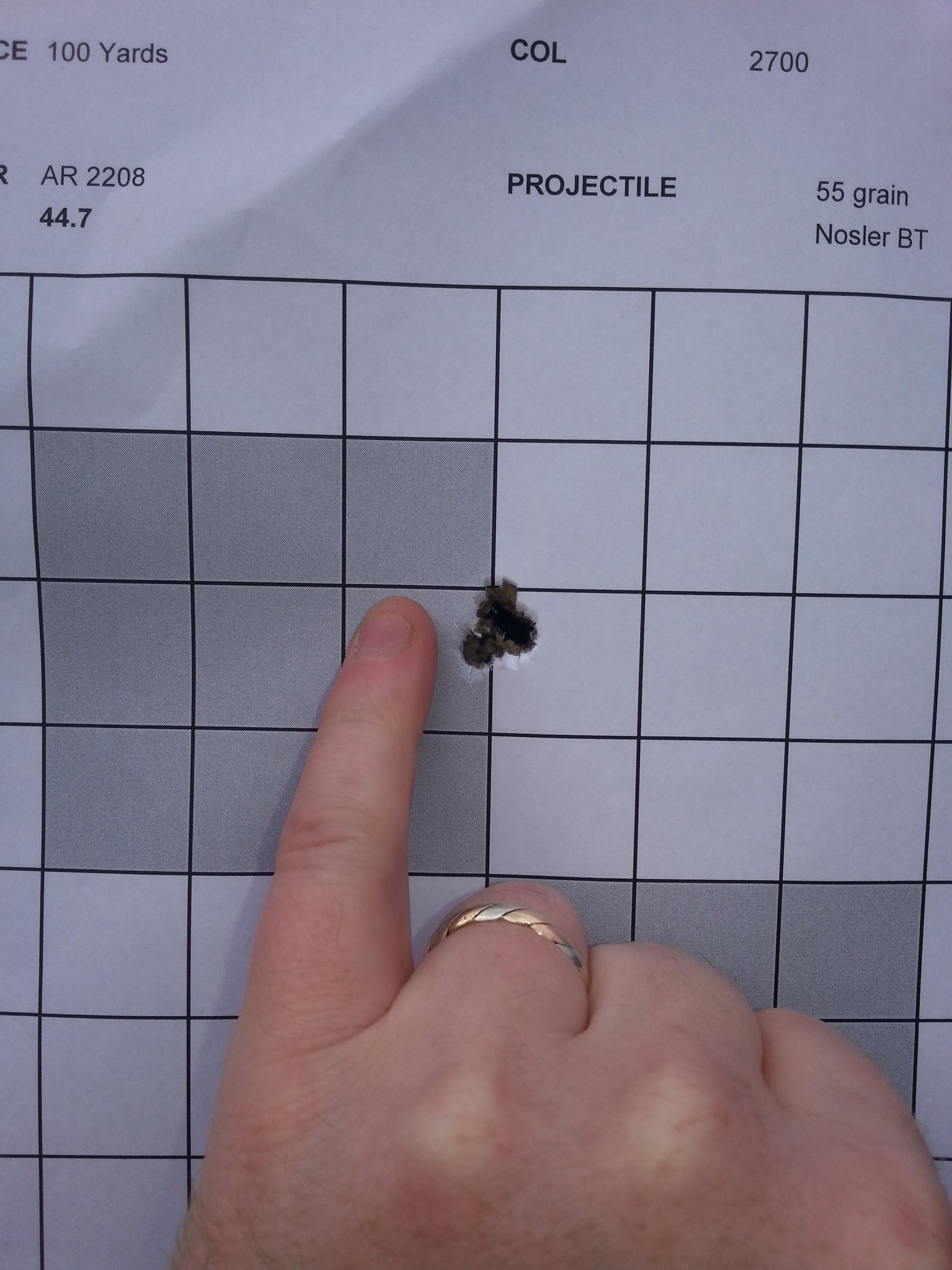

Somewhere in the middle of the loads I had 2 bullets touching and pulled the third :-[ booger. Then the groups got bigger and started to close up again until the penultimate load 42.7g. I got three rounds at 100m with a 0.28inch measurement outside edge to edge. The last group first round was too high pressure, could barely open the bolt, so we called it quits.

So summary. I think I have a load. Need to chrony it now. But why the resistance in closing the bolt, and what do I do about it?

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 9 of 9

Thread: first time reloading.

Hybrid View

-

16-02-2014, 07:26 PM #1Member

- Join Date

- Dec 2011

- Location

- West of Christchurch

- Posts

- 1,716

first time reloading.

-

16-02-2014, 07:42 PM #2

Case without bullet chambering sounds like you are seating projectile too far out, so it is getting jammed into lands and bolt will be tight or impossible to close. You getting any marks on the projectiles ?

With most projectiles it is better (more accurate) to measure base to ogive with a comparator.

You can measure the lands for you chamber / projectile combo using something like the Hornady Oal Gauge

The centre spindle you talk about is called the decapping rod / expander ball. Those are probably sizing dies, not seating dies.

Nice looking group

Last edited by ebf; 16-02-2014 at 07:54 PM. Reason: OAL gauge not Headspace gauge, doh !

Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

16-02-2014, 08:35 PM #3Member

- Join Date

- Dec 2011

- Location

- West of Christchurch

- Posts

- 1,716

-

16-02-2014, 07:45 PM #4Member

- Join Date

- Feb 2014

- Location

- Cambridge

- Posts

- 686

The projectile may be touching the rifling.

Did the projectile have rifling scratches on it when you ejected the test round?

It may have pushed the projectile slightly further into the case as well so check the length with your measuring stick to check if it did shorten as this will confirm that the projectile is engaging the rifling.

You will need to seat the bullet slightly deeper if this is the cause of your issue.

Good luck.

Nice group.

-

16-02-2014, 08:21 PM #5

And also, if you got to the stage you had real trouble opening your bolt you went WAY too far. You would have felt it starting to get heavier before then surely?

Load a dummy round and colour the projectile in marker pen, chamber it and eject it. Look if it has marks where it has contacted the lands. Another way to do it is to remove the firing pin assembly ( a remington you push the wee square edge on the rear of the bolt onto something and slide a 20c coin into the slot that appears then unwind it from the bolt body) from the rifle and you can get a feel what it's like with an empty case and a loaded case. It's very noticeable if the projectiles are getting jammed.

-

16-02-2014, 08:33 PM #6

Also check case over all length.

"Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

-

16-02-2014, 08:37 PM #7

and that you are not trying to crimp and seat by having the seating die set to low. this can push the shoulder out enough to make tight chambering.

"Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

-

16-02-2014, 09:04 PM #8Member

- Join Date

- Dec 2011

- Location

- West of Christchurch

- Posts

- 1,716

Nope, checked the crimp function isn't set on the hornady dies.

-

18-02-2014, 09:33 PM #9

Check the case length and trim it. Even new brass can need trimming.

If you take the case and bullet that was hard to close the bolt, adjust the seating die in by 20thou and check again in the rifle. If ok, the bullet was seated to far out and the projectile was touching the rifling as mentioned. If the bolt is still hard to, case is either touching the rifling or not fully sized.

Sent from my iPad using Tapatalk

Similar Threads

-

Long time wannabee hunter, short time FA "owner"

By peril 787b in forum IntroductionsReplies: 10Last Post: 07-04-2014, 08:50 AM -

Long time lurker, first time poster

By Brakelie in forum IntroductionsReplies: 16Last Post: 19-08-2013, 01:04 PM -

first time there

By Kiwiman in forum HuntingReplies: 4Last Post: 04-06-2013, 01:01 PM -

Howdy, 1st time poster long time gun nut signing in.

By Chupacabra in forum IntroductionsReplies: 14Last Post: 28-05-2013, 07:15 PM -

Time

By Shooter in forum Questions, Comments, Suggestions, Testing.Replies: 1Last Post: 16-02-2012, 12:15 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

3Likes

3Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks