Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 31 to 45 of 51

-

25-04-2022, 08:13 PM #31

-

-

25-04-2022, 08:16 PM #32

Yep that was why I had two lots of 5 seated at same depth. One to check group size and velocity and the other with magnetospeed off and to check group size again to see what impact it had. Having it on the barrel may have improved my groups but never really got to that stage to verify

.

.

-

25-04-2022, 08:27 PM #33Member

- Join Date

- Sep 2013

- Location

- Wairarapa

- Posts

- 1,426

@Snowgrass

Ex instrumentation calibrator here and user of both balance beam and electronic scales.

The only reason I use electronic scales is because mine are attached to a powder dispenser. Beam scales in general are inherently more reliable.

Electronic scales generally work well, however there are many more ways they can be inaccurate without you realising. They can drift after zeroing or the span may be inaccurate (0 reads 0, 10 reads 10.1 20 reads 20.2 .... 80 reads 80.8) or you might breathe on them and cause them mis-read.

It is probably OCD on my part but I like to use my beam scales to weigh what my powder dispenser throws on about every tenth throw. If you have two separate instruments giving the same reading repeatedly, chances are they are both repeatedly accurate.

If you are struggling to trust your beam scales the best thing to buy is some check weights. They are great for validating any scales you have and removing doubt.

I like to set my scales for the powder weight that I am using and then put the equivalent weight in check weights on the scales to ensure they are reading accurately at weight and not just at zero. It can be reassuring to use the check weights every 10-15 loads to ensure the scales have not drifted.

Keep check weights in a sealed container so they don't get dust on them.

Also probably doesn't make much difference but it is good practice to handle the checkweights with tweezers only.Last edited by longshot; 25-04-2022 at 08:39 PM.

-

25-04-2022, 08:37 PM #34

Thanks @longshot, that’s probably my first move (and cheapest). I’ll pull a few of the rounds I loaded the other day and verify against the check weights as well to see if they match up.

-

25-04-2022, 08:48 PM #35Member

- Join Date

- Sep 2013

- Location

- Wairarapa

- Posts

- 1,426

Good move.

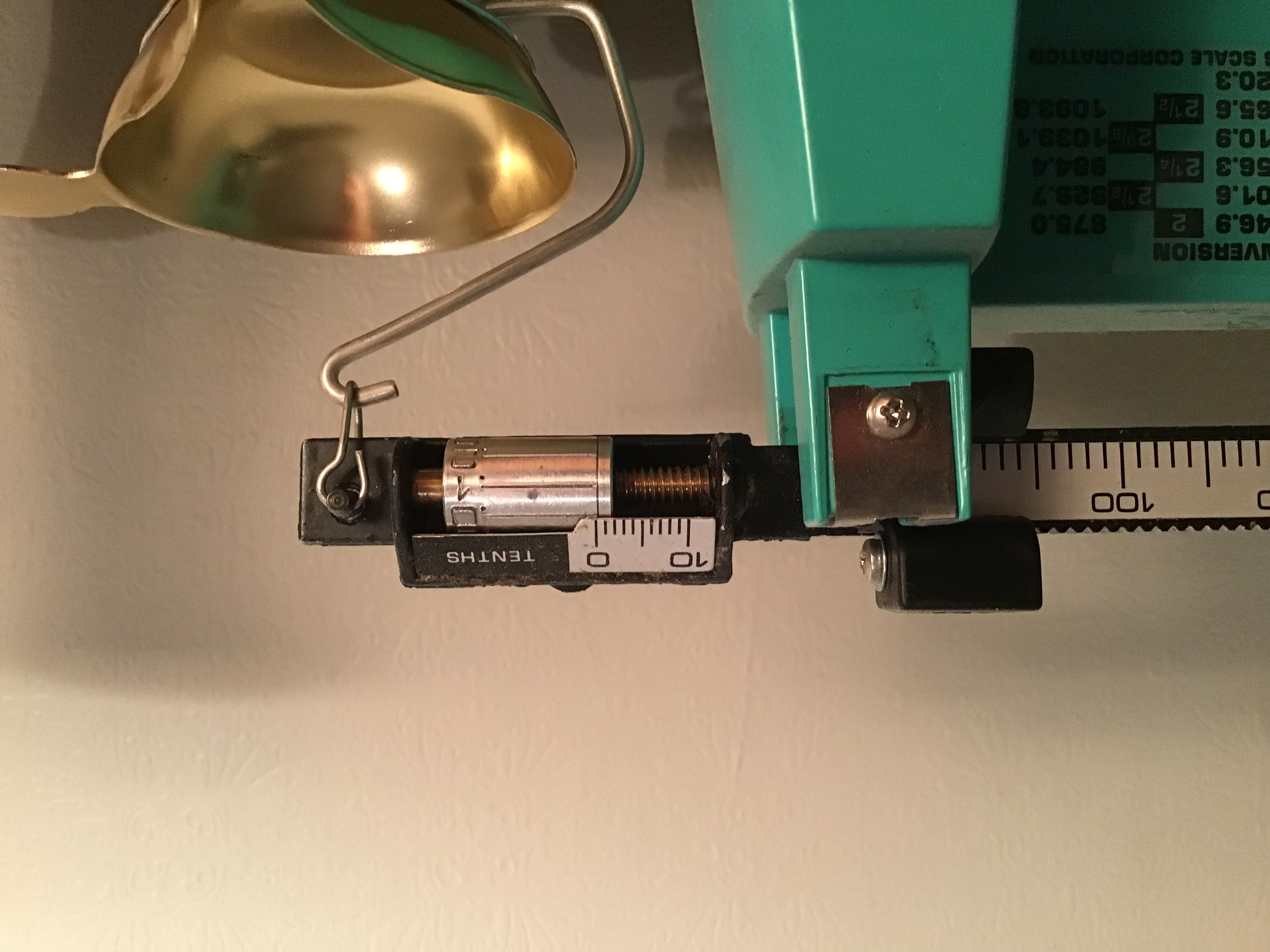

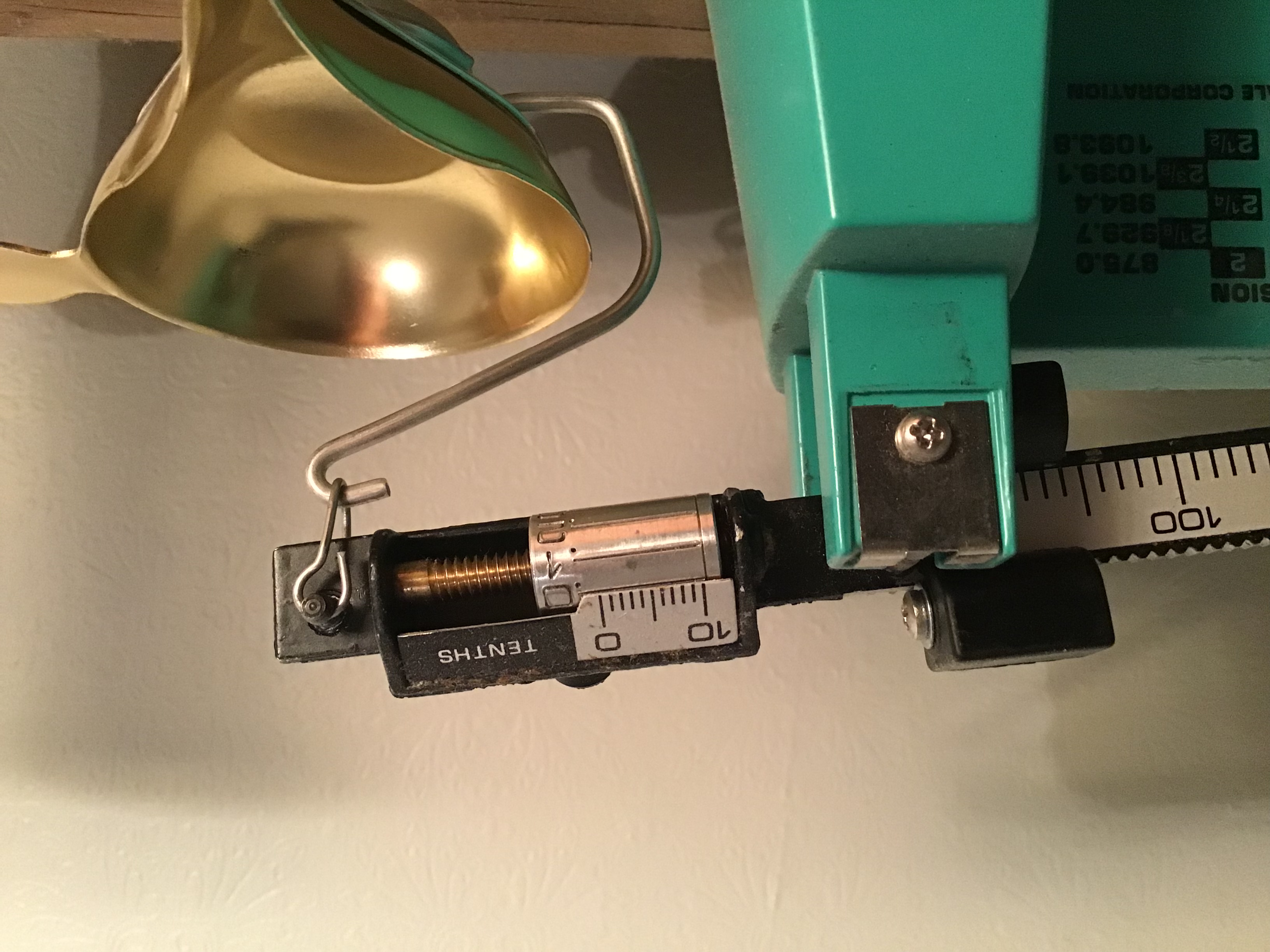

Do you want to post a photo showing how the fixed zero doesn't line up with the zero on the screw weight?. Not sure that I can offer any advice there but I would like to understand it better in case I can help.

You maybe already doing so but it also helps to have the scales at eye height (prevents parallax error).

If that isn't ergonomic you can also mount a cheap webcam aimed at your scales and have a laptop screen angled toward you. (The one thing to be careful of here is that the screen doesn't freeze causing an incorrect powder weight.

-

25-04-2022, 09:14 PM #36

-

25-04-2022, 09:17 PM #37

I believe that is your 10ths of a grain..and its reading correctly?????

-

25-04-2022, 09:20 PM #38

eg...your numbers to the left of centre are your 10grn-100grn lines...you roll your dial on screw along and the line on left of round steel dial line up with number 0-10grains and the .0-.9 on end will be your 10ths of a grain.....

-

25-04-2022, 09:21 PM #39

you would need 10.1grains of weight in the pan for beam to be level in 2nd photo.

-

25-04-2022, 09:25 PM #40

“ I believe that is your 10ths of a grain..and its reading correctly?????”

Correct, just offset slightly. Doesn’t affect anything just slightly annoying with the OCD. Would need 10.0 grains to re zero pan in second photo.

I’m playing around with the sliding weight on the beam with the scales zeroed.The weight can sit in the notch on the beam but be ever slightly off one way or tother and it puts the scale out of zero. The most I’ve got is .4 grains. So there’s room to re zero each time and be inconsistent between loading sessions, which may explain why I thought my average velocity was down the other day over last time.

-

25-04-2022, 09:29 PM #41

.4 of a grain is 61.4 times able to be fitted into a 24.5grain load...so its ?????? 100 devided by 61.4 = sweet fark all %

-

25-04-2022, 09:29 PM #42Member

- Join Date

- Jul 2012

- Location

- Hamilton

- Posts

- 755

Depends what youíre objective is. For a hunting set-up, itís probably not necessary to continue with the chronograph during seating depth test. But it is worth knowing that your velocity may change with seating depth as internal volume changes and your ES/SD

I look for where several groups with low ES/SD coincide with small group size. Itís easy to get sucked in by a single spectacularly small group and ignore the so-so ES/SD, but this is unlikely to consistently hold-up at distance.

I run a tuner-brake on my match rifle. The weight is maybe 50-75grams and only 1/8th of a turn will take the load out of tune on a 26Ē Medium Palma contour barrel (barrel weighs 3kg). So the effect of the MS on your groups versus without, is very real.

-

25-04-2022, 09:33 PM #43

and if .4 is the most you have ever been able to get...you will normally/usually be getting an error that is less than 0.4 again sweet fark all %

if you use a powder thrower for say 100 loads...your difference between one load and the next will be minimal and wont make enough difference to matter your state of heart beat could well change impact more....

I firmly believe you are over thinking this.

-

25-04-2022, 10:23 PM #44Member

- Join Date

- Sep 2013

- Location

- Wairarapa

- Posts

- 1,426

That is an example of inaccurate span that I mentioned earlier. In theory and most likely in practice it won't affect outputs but double weighing will confirm this.

Most instrumentation has this phenomenon, many car speedos are accurate at ~20kph but out by ~10% by the time they are up to 80kph. On some instrumentation equipment it is adjustable so some extent and on some not.

The only fix here would be to alter the pitch of the thread by 2/5 of 3/8 of !@$# all, too much hassle and likely not effective in the end, just something you have to live with.

One possible fix for the slide weight situation though is to gently loosen the screw on the right and move the washer under the screw so that it engages with the beam notch 'floors'. From what you are saying, the washer could be set high and hitting the notch 'walls' thereby allowing the beam slide weight to move slightly within the notches.

One other area for improvement would be to bend the wire that the pan hangs from so the top hook hangs more vertically. At the wide curve level with the top of the pan would be best, just make the curve a bit wider. As things are currently it looks like the hook has potential to slide side to side in the hanging loop. If it slides to the right this would show a heavier charge then what there is and to the left will give a lighter charge. You will be able to judge if it can slide as it is, it is hard to judge from a photo.Last edited by longshot; 25-04-2022 at 10:30 PM.

-

25-04-2022, 10:43 PM #45

Good observations, I hadn’t looked at the pan mounting. If I got really enthusiastic I could screw the brass screw the weight is on out a fraction but I’m sure it’s got locktight from a quick test so don’t want to damage anything for no real gain. I’ll get hold of some check weights which should negate any deviations on the beam balance weight by checking each time it’s moved.

Similar Threads

-

Solar charges for devices

By deepsouthaussie in forum Gear and EquipmentReplies: 34Last Post: 22-06-2017, 02:35 PM -

Whitianga launching charges

By Pengy in forum FishingReplies: 11Last Post: 22-12-2013, 08:43 PM -

Permit Charges.

By Malhunting in forum HuntingReplies: 23Last Post: 24-09-2012, 12:01 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

57Likes

57Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks