So tried to do some 300blk reloads with cast 151gr bullets today, didn't go so well......

Using Hornady "custom grade" die set with what I think is a universal 30cal seating die, the bullets have a huge step in the tip from the seating stem.

The die set came with two different seating stems (on for VLD type bullets) but both had the same effect.

The cases are unfired Hornady ones that I ran through the sizing dies.

There seemed to be a bit of resistance when seating the bullets, more than I am normally used to but ususally use a bushing die.

Is this a normal issue to have with cast bullets?

Am I doing something wrong?

Is the seating die rubbish?

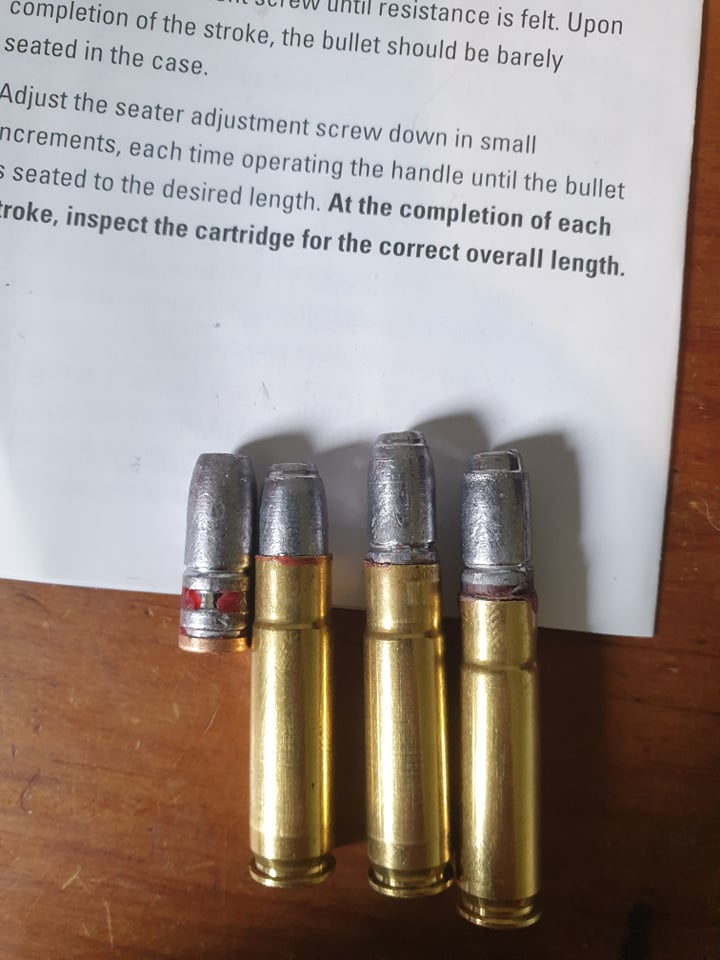

Have attached an image, ignore the different seating depths.

Can see the furtherest Right bullet has a bigger step in the tip.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 1 to 15 of 20

Thread: Issues Seating Cast Bullets

Threaded View

-

22-09-2021, 01:52 PM #1

Issues Seating Cast Bullets

Similar Threads

-

.303 Cast bullets

By shooternz in forum Reloading and BallisticsReplies: 19Last Post: 26-06-2021, 05:33 PM -

Cast Bullets

By gimp in forum Reloading and BallisticsReplies: 9Last Post: 28-05-2013, 12:56 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

19Likes

19Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks