I have this old Lachmiller 12g Shotgun press. Press is complete and obvious to work..dies not so much.

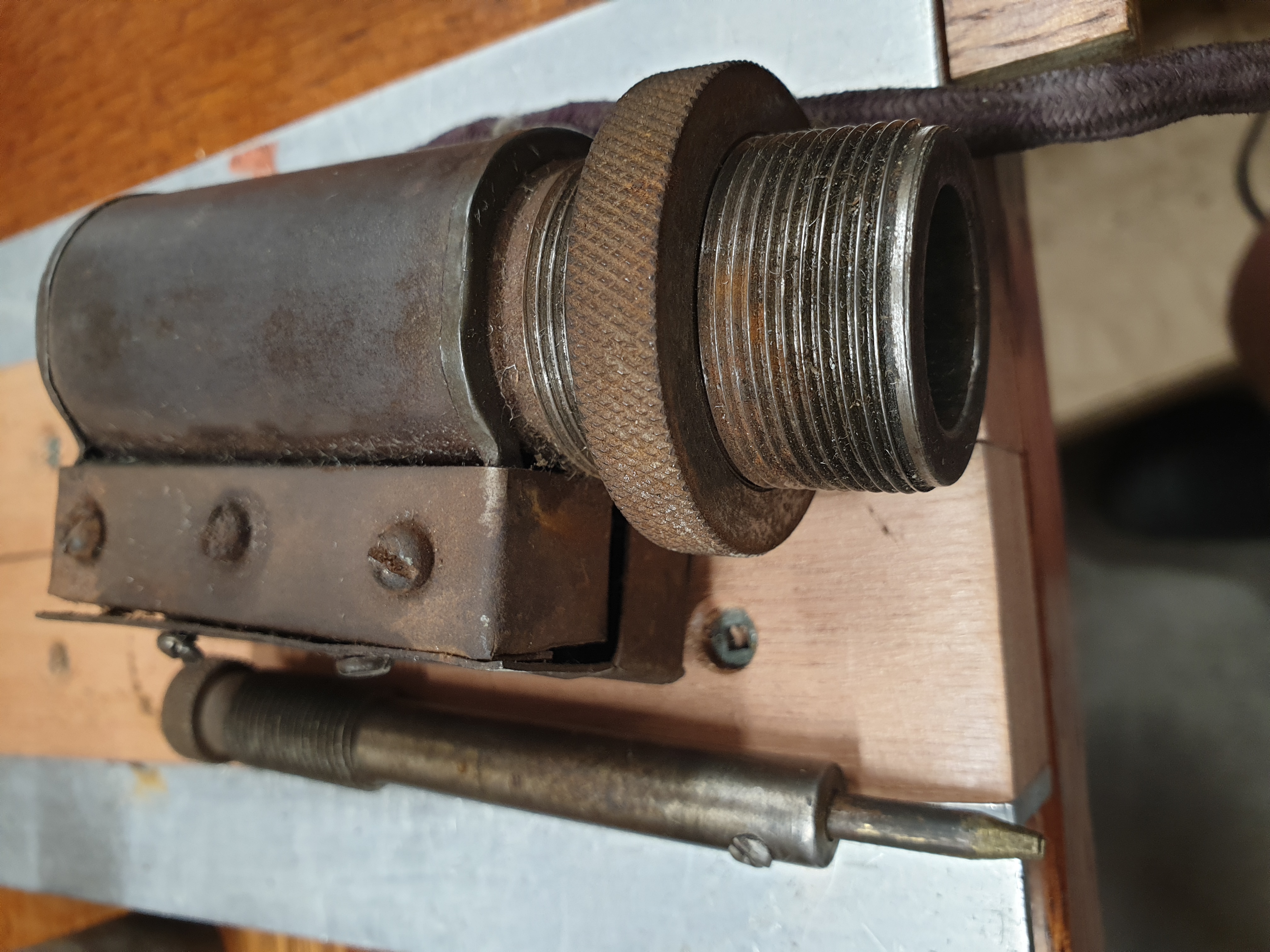

There is a die assembly stamped Lachmiller 12g reloading unit. It came to me assembled with two springs and a plunger running into a removable internal collar, no marks on the top shaft to indicate pressure on a wad. As the plunger does not plunge past the mouth of a case I'm kind of lost as to its purpose unless it performs a slight roll crimp on brass over an overshot card. That is my best guess. There is a second stem/plunger marked 12g which has the pressure gradations marked at the top. It does not fit the same internal collar the previous one uses so I guess that one is lost. De-priming appears to have been done off the press by the previous owner, the Lachmiller Die Unit may have originally had an insert for this but not there now. A couple of long depriming rods of the whackamole type came in the box. Easily done so no issues there. Surprise surprise, the original priming arm assembly is present and intact.

There is also a somewhat random tube with a star crimp assembly in it that does not appear to fit the press. Also a couple of similar tubes with knurled caps that I have no idea about.

Finally, there is a die with a heating element. It has a center pin like a decapping pin. The only thing I can think this is is a die for annealing brass cases. I'm not game to plug it in lol. If you know more do please tell.

Photos below.

My interest in the press is multi-strand. First I just love good old gear. The press is cast iron at the top, O Frame, the linkage arms and bottom piece, while all painted the same olive-green, are solid brass!

Second I wanted a press dedicated to reloading 12g brass hulls. I have an RCBS Cowboy Shotshell Die set for brass. Unfortunately the thread on the Lachmiller is different.

Probably the sensible option is to bore and sleeve the press to accept the RCBS dies. And, perhaps, get or have made a thread-in sleeve a- la RCBS and Lee Classic Cast presses to accept standard dies. If the gape on the O-Frame would accept a 50 BMG shell this approach could be appealing. It does not. And even if it did, maybe the brass bottom linkages would not be up for that.

So, if anyone knows anything about these old dies I'd be keen to hear from you. I have other options for loading shotshells but this has kind of caught my fancy. They must be 80 plus years old.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 17

Hybrid View

-

10-05-2023, 06:58 PM #1Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,615

Lachmiller Shotgun Press - looking for info

I know a lot but it seems less every day...

-

11-05-2023, 10:08 AM #2Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,615

Ah well, I guess it was a long shot hoping for info here..I guess the press came into NZ with someone a long time ago and has probably been in a box since they passed. Worrh one bump perhaps but I'll post it up on some US forums and see what happens. I am real curious about that die with a heater element. . Maybe someone's great grandson somewhere remembers something lol

I know a lot but it seems less every day...

-

11-05-2023, 10:25 AM #3

the funny star crimpy tube is possibly just a funnel,it directs shot down into the wad... and the rod with two diameters and collar COULD BE THE pusher downer thingy to poke wads down into case and close off/finish off crimp

75/15/10 black powder matters

-

11-05-2023, 10:18 AM #4

I can answer half of the puzzle...... the rods are indeed for deprimeing as per LEE whackamole...the two metal tubed with knurling on one end..look for all intents like LEE whackamole also.....it will fit down over a case and semi resize rim..... will have slight taper inside one end to give the crimp a bit more push inwards to be finished off with plunger that fits snuggly inside the smaller hole end.....dowel will work. the star crimp bit...weird all me LEE ones are hard plastic,you fit over shell and tap downwards to start the star foming..best if turn gently untill flops into existing crimps.

is/does the middle rod as shown in first photo have a hollow end??? if so its for priming... the primer is placed on flat surface shell placed on top in correct position and shell tapped down onto it...sounds more dodgy than it is.75/15/10 black powder matters

-

11-05-2023, 10:29 AM #5

-

11-05-2023, 10:33 AM #6

you dont need to roll crimp brass......over shot card and tiny bit of adheisive...glue/nail polish etc and job done....

75/15/10 black powder matters

-

11-05-2023, 10:38 AM #7

In the end that's all I used to do for my 12g black powder loading. A ring of PVA around the outer edge of the over shot card. The PVA doesn't exactly stick well to the hull but I never had a card come loose in the second barrel of my old sbs when first barrel fired.

Did the same with my 16g which I didn't have reloading gear for.

-

13-05-2023, 06:03 PM #8Member

- Join Date

- Feb 2023

- Location

- Chch

- Posts

- 180

The round tube with the wad guide mounted in it is off a Lyman easy press, case fits inside, unit inserted in press,

Wad placed in top and press handle lowered pushing wad down into case.

I have shooters digest books going way back, I'll check tomorrow if they are old enough to list any thing like that pressLast edited by Skeetshooter; 13-05-2023 at 06:11 PM.

-

13-05-2023, 06:45 PM #9Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,615

Thanks team. I'm am now definitely leaning toward rethreading the press to take the current RCBS Cowboy 12g dies for brass cases.

I know a lot but it seems less every day...

-

11-05-2023, 10:30 AM #10Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,615

Yeah thanks Mickey, It became obvious that it was a collection of bits from various kits. Its a shame tge inner collar for the 12g wad seating plunger is missing, that would actually make the press usable for priming, wad seating and the slight roll crimp used for brass. I suspect the main die body will also resize.

If I was a lathe guy I'd have a go at turning a guide collar with the crimp one as a template. Can't be that hard. But I'm not.

My sparky is into reloading so I'll get him to check the heater die before I try annealing with it. I know a lot but it seems less every day...

I know a lot but it seems less every day...

-

11-05-2023, 10:32 AM #11

bottom is MRC top is LEE

Surprisingly effective but rather slow..... great for the different loads a fella may want to make up and definately cheaper than factory in .41075/15/10 black powder matters

-

13-05-2023, 06:01 PM #12Member

- Join Date

- Feb 2023

- Location

- Chch

- Posts

- 180

The "heater die" is a case conditioner,

Made to heat and redistribute the wax in the older paper type American cases

-

13-05-2023, 06:43 PM #13Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,615

-

13-05-2023, 07:24 PM #14Member

- Join Date

- Mar 2022

- Location

- Catlins

- Posts

- 537

Will you strip it back, paint the frame and polish up the brass??

“Age is a very high price to pay for maturity”

-

13-05-2023, 07:56 PM #15Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,615

Similar Threads

-

Arbor press V single stage press, thoughts?

By steven in forum Reloading and BallisticsReplies: 4Last Post: 04-11-2013, 10:51 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

5Likes

5Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks